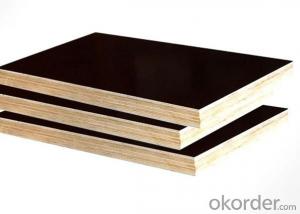

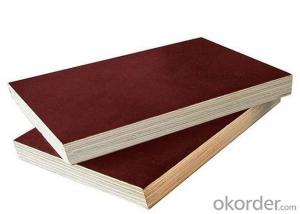

1/2 CDX Marine Film Faced Plywood with Best Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Item:film faced plywood

Size:1220x2440mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,customer's thickness is available

Color:Brown,Black,Red

Description:

Product Names | Plywood,Commercial plywood,veneer faced plywood |

Place of Origin | LINYI ,SHANDONG PROVINCE ,CHINA |

Face/back | Melamine, Bintangor, Pencil Cedar, Keruing, Poplar, Birch,Pine,Maple, Hardwood, Ash, Oak,Teak and as your requested |

Core | Poplar, Hardwood, Hardwood Combi, Birch, eucalypts, as your requirement. |

Size | 1220*2440/1250*2500mm and as your requirement |

Thickness Torlerance | 2.7-6mm: +/-0.2mm , 6-30mm: +/-0.5mm |

Grade | BB/BB GRADE, BB/CC GRADE

|

Glue | E0,E1,E2,MR,MELAMINE |

Moisture | 8%-14% |

Certificate | ISO9001,CE,SGS |

Brand name | CMAX |

Usage | construction,Furniture,decoration,packing. |

Joint way | Overlap joint,end joint,scraf joint,finger joint |

Packing | Inner with plastic bag, Outside are cover with plywood or Corrugated paper and then steel tap for strength. |

Payment | TT, L/C at sight |

Delivery time | 15 days after receiving downpayment or L/C |

Min order | 21 m3 , 21CBM/20FCL,55CBM/40HQ |

Supply ability | 10000 CUBIC, best service , your best choice

|

Features:

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

FAQ:

1.Can I be your agent?

Yes, welcome to deep cooperation. We have big promotion in the market now. For the details please contact with our overseas manager.

2.Is OEM available?

Yes, OEM is available. We have professional designer to help your brand promotion.

3.Is the sample available?

Yes, samples are available for you to test the quality.

4.Are the products tested before shipping?

Yes, all was qualified before shipping. We test every batch every day.

5.What's your quality guarantee?

We have 100% quality guarantee to customers. We will be responsible for any quality problem.

6.What's benefit will you bring?

Your client satisfied on the quality.

Your client continued orders.

Your can get good reputation from your market and obtain more orders.

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: What are the further processing of plywood?

- plywood plywood through mechanical finishing or gluing, such as cutting, profiling sawing, hitting, drilling, milling and other processed plywood

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- High-quality urea-formaldehyde glue / melamine glue / phenolic glue can reach E0 level, E1 level, that can be used directly for indoor

- Q: Plywood is a common material for furniture?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences.

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- the difference between the process: multi-layer solid wood flooring will be a layer of each layer of scientific criss-cross, to eliminate internal stress, at present, its layers have grown from 7 to 9 layers, 11 layers

- Q: Multilayer board and plywood difference

- A group of boards are usually made of mutually adjacent panels in the direction of the adjacent layers.

- Q: The Preparation of plywood ingredients

- Loose loose side In the process of peeling or slicing, the side of the board and the knife contact side, this side due to reverse expansion and often produce a bottle peeling or cut fissure.

- Q: What are the defects in plywood material?

- Fissure check The short separation of the panel fiber usually does not start from the side of the board, not all extending through the thickness of the veneer.

- Q: What is medium density fiberboard

- Its thickness specifications are 2.7,3,3.5,4,5,5.5,6,7,8 mm, commonly used specifications are 3,3.5,4 mm.

- Q: Why is the plywood commonly used in the singular layer

- and the back of the stripes) from the beautiful and do not look good

Send your message to us

1/2 CDX Marine Film Faced Plywood with Best Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords