All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

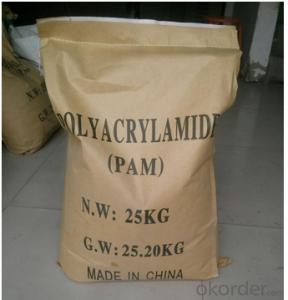

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of polymers in the field of bioelectronics?

Polymers play a crucial role in the field of bioelectronics as they enable the development of flexible and biocompatible devices. These polymers can be used as substrates, encapsulation materials, and conductive components in various bioelectronic devices such as sensors, interfaces, and implants. Their unique properties, including flexibility, stretchability, and biocompatibility, make them ideal for integrating electronics with biological systems, allowing for improved signal transmission, reduced tissue damage, and enhanced biointegration.

How are polymers used in the production of biodegradable sutures?

Polymers are used in the production of biodegradable sutures by providing a flexible and strong material that can be easily woven into threads. These polymers are typically derived from natural sources such as plants or animals and are designed to break down over time, reducing the need for suture removal. This allows for safer and more environmentally friendly wound closure, as the sutures degrade and are eventually absorbed by the body, eliminating the need for manual removal.

What is rotational molding?

Rotational molding is a manufacturing process that involves heating and rotating a hollow mold filled with a powdered material, such as plastic, until it coats the interior walls of the mold and forms a desired shape. Once the material is evenly distributed and fully melted, the mold is cooled to solidify the product. This method is commonly used to produce large, hollow and seamless plastic products with complex shapes, such as storage tanks, playground equipment, and automotive components.

Wholesale Polymer from supplier in Zimbabwe

We understand the unique challenges and requirements of the Zimbabwean market and have tailored our products and services to meet these needs. Whether you are looking for high-quality polymer materials for construction, packaging, or industrial applications, we have a wide range of options to choose from.

Our sales team is dedicated to providing you with personalized assistance, ensuring that you find the right polymer products for your specific requirements. They are knowledgeable about the latest industry trends and can offer expert advice to help you make informed decisions.

In addition to our sales support, we also offer comprehensive quotations to help you budget and plan your projects effectively. Our team will work closely with you to understand your needs and provide competitive pricing options.

Technical support is another key aspect of our service offering. We have a team of experienced engineers and technicians who can provide guidance and assistance throughout the project lifecycle. Whether you need help with product selection, installation, or troubleshooting, we are here to support you every step of the way.

Being a subsidiary of CNBM, a Fortune Global 500 company, gives us access to vast resources and expertise. This allows us to offer you convenient one-stop polymer procurement solutions, saving you time and effort. We have established strong relationships with reliable suppliers and manufacturers, ensuring that we can deliver high-quality products on time.

Our years of operating in Zimbabwe have given us invaluable market experience. We understand the local regulations, industry standards, and customer preferences, making us the ideal partner for your projects. We are committed to building long-term relationships with our clients, providing exceptional service and support to help you achieve your goals.

Choose us as your polymer supplier in Zimbabwe and experience the convenience, expertise, and reliability that we bring to the table. Contact us today to discuss your requirements and let us help you find the best polymer solutions for your projects.

Our sales team is dedicated to providing you with personalized assistance, ensuring that you find the right polymer products for your specific requirements. They are knowledgeable about the latest industry trends and can offer expert advice to help you make informed decisions.

In addition to our sales support, we also offer comprehensive quotations to help you budget and plan your projects effectively. Our team will work closely with you to understand your needs and provide competitive pricing options.

Technical support is another key aspect of our service offering. We have a team of experienced engineers and technicians who can provide guidance and assistance throughout the project lifecycle. Whether you need help with product selection, installation, or troubleshooting, we are here to support you every step of the way.

Being a subsidiary of CNBM, a Fortune Global 500 company, gives us access to vast resources and expertise. This allows us to offer you convenient one-stop polymer procurement solutions, saving you time and effort. We have established strong relationships with reliable suppliers and manufacturers, ensuring that we can deliver high-quality products on time.

Our years of operating in Zimbabwe have given us invaluable market experience. We understand the local regulations, industry standards, and customer preferences, making us the ideal partner for your projects. We are committed to building long-term relationships with our clients, providing exceptional service and support to help you achieve your goals.

Choose us as your polymer supplier in Zimbabwe and experience the convenience, expertise, and reliability that we bring to the table. Contact us today to discuss your requirements and let us help you find the best polymer solutions for your projects.

Hot Search

- Fiberglass Chopped Strand in Sri Lanka

- Fiberglass Mesh Cloth in Guyana

- Composite Pipes in Montenegro

- FRP Pultrusion Profiles in Uruguay

- Fiberglass Mat Tissue in Albania

- Fiberglass Fabrics in Iceland

- Fiberglass Mesh in Chad

- Composite Tank in Egypt

- Fiberglass Mesh tape in Switzerland

- Polymer in Angola