All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can electrolytic tinplate coil be used for cosmetic packaging?

Yes, electrolytic tinplate coil can be used for cosmetic packaging. It is commonly used due to its excellent corrosion resistance, durability, and ability to maintain product freshness. Additionally, the tin coating provides an attractive and glossy appearance, making it suitable for cosmetic packaging.

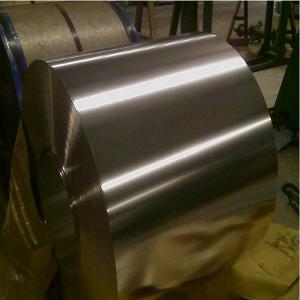

What are the typical production processes for electrolytic tinplate coil?

The typical production processes for electrolytic tinplate coil involve several steps. First, cold-rolled steel coils are cleaned and pickled to remove any impurities. Then, they undergo an electrolytic tinning process, where the steel coils are immersed in an electrolyte solution and an electric current is passed through them. This causes a layer of tin to be deposited on the steel surface.

After tinning, the tin-coated coils are rinsed and dried to remove excess moisture. They are then subjected to a tempering process, which involves heating and cooling to improve their mechanical properties and enhance their formability.

Next, the tinplate coils undergo various surface treatments, including oiling to prevent corrosion and improve handling. They may also undergo passivation, where a thin layer of chromium oxide is applied to further protect the tin coating.

Finally, the tinplate coils are trimmed, inspected for quality, and packed for shipment. These processes ensure the production of high-quality electrolytic tinplate coils that are widely used in the packaging industry for items such as cans and containers.

What are the different printing options available for electrolytic tinplate coil?

The different printing options available for electrolytic tinplate coil include lithographic printing, flexographic printing, and screen printing.

Can electrolytic tinplate coil be used for packaging of chemicals?

Yes, electrolytic tinplate coil can be used for packaging of chemicals. It provides excellent resistance to corrosion and is known for its durability, making it suitable for packaging various chemicals. Additionally, the tin coating on the coil acts as a barrier, preventing any reaction between the chemicals and the metal, ensuring the safety and integrity of the packaging.

Can the coil be used in marine applications?

Yes, the coil can be used in marine applications as long as it is designed and built to withstand the harsh marine environment, including exposure to saltwater, moisture, and corrosion.

Wholesale Electrolytic Tinplate Coil from supplier in Zimbabwe

Our team is knowledgeable about the specific requirements and regulations in Zimbabwe, ensuring that we can provide tailored solutions to meet your needs. We work closely with manufacturers to ensure the highest quality standards are met and that products are delivered on time and within budget.

In addition to supplying Electrolytic Tinplate Coil products, we also offer technical support services. Our team of experts can provide guidance and assistance in selecting the right products for your specific applications, as well as providing technical advice on installation and maintenance.

We understand the importance of competitive pricing in the Zimbabwean market, and we strive to offer the most cost-effective solutions without compromising on quality. Our strong relationship with manufacturers allows us to negotiate favorable prices and pass those savings on to our customers.

At CNBM, we are committed to providing excellent customer service. Our dedicated sales team is always available to answer any questions or concerns you may have, and we pride ourselves on our prompt response times. We believe in building long-term relationships with our customers, and we strive to exceed your expectations with every interaction.

Whether you are a large-scale industrial project or a small business, we have the expertise and resources to meet your Electrolytic Tinplate Coil needs in Zimbabwe. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects.

In addition to supplying Electrolytic Tinplate Coil products, we also offer technical support services. Our team of experts can provide guidance and assistance in selecting the right products for your specific applications, as well as providing technical advice on installation and maintenance.

We understand the importance of competitive pricing in the Zimbabwean market, and we strive to offer the most cost-effective solutions without compromising on quality. Our strong relationship with manufacturers allows us to negotiate favorable prices and pass those savings on to our customers.

At CNBM, we are committed to providing excellent customer service. Our dedicated sales team is always available to answer any questions or concerns you may have, and we pride ourselves on our prompt response times. We believe in building long-term relationships with our customers, and we strive to exceed your expectations with every interaction.

Whether you are a large-scale industrial project or a small business, we have the expertise and resources to meet your Electrolytic Tinplate Coil needs in Zimbabwe. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects.