All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the potential applications of shape memory polymers?

Shape memory polymers have a wide range of potential applications in various industries. Some potential applications include biomedical devices such as stents, sutures, and drug delivery systems, as they can be designed to change shape in response to body temperature or other stimuli. They can also be used in aerospace engineering for morphing aircraft structures, in textiles for wrinkle-resistant clothing, and in electronics for flexible and self-repairing circuitry. Additionally, shape memory polymers have potential applications in robotics, automotive, and packaging industries, where their ability to change shape and return to their original form can be utilized for various purposes.

What are the main methods of polymer modification?

The main methods of polymer modification include blending, grafting, crosslinking, and copolymerization.

How do polymers degrade over time and what are the factors that accelerate degradation?

Polymers can degrade over time through various processes like hydrolysis, oxidation, and photodegradation. Hydrolysis occurs when the polymer chains react with water molecules, leading to the breaking of chemical bonds and eventual degradation. Oxidation happens when polymers react with oxygen, causing chain scission and degradation. Photodegradation occurs when polymers are exposed to UV radiation, leading to the breaking of chemical bonds.

Several factors can accelerate polymer degradation. Higher temperatures can speed up degradation reactions by providing more energy for chemical reactions to occur. Exposure to certain chemicals like acids, bases, and solvents can also accelerate degradation by promoting chemical reactions that break down the polymer chains. Additionally, exposure to UV radiation can intensify photodegradation. Other factors include mechanical stress, humidity, and the presence of microorganisms.

How can the degradation of polymers be prevented or slowed down?

The degradation of polymers can be prevented or slowed down through various methods. One way is by adding stabilizers to the polymer formulation, which act as antioxidants or UV absorbers, preventing degradation caused by oxidation or exposure to sunlight. Another approach is to modify the polymer structure, such as crosslinking or blending it with other materials, to enhance its stability and resistance to degradation. Additionally, proper storage and handling of polymers, such as storing them away from heat, light, and moisture, can help prevent degradation.

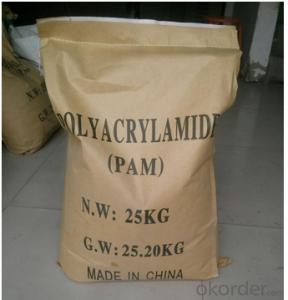

Wholesale Polymer from supplier in Vietnam

With our expertise and strong network, we can offer competitive prices and reliable supply chains for various Polymer products such as polyethylene, polypropylene, PVC, PET, and more. Our team of professionals is committed to providing exceptional customer service and ensuring that your requirements are met efficiently.

Whether you are looking for raw materials for manufacturing, packaging solutions, or specialized Polymer products, we have the knowledge and resources to fulfill your needs. Our technical support team can assist you with product selection, application guidance, and troubleshooting to optimize your processes and enhance product performance.

At CNBM, we prioritize quality and sustainability. We work closely with reputable manufacturers to ensure that our Polymer products meet international standards and comply with environmental regulations. By choosing us as your Polymer supplier in Vietnam, you can trust that you are receiving products of the highest quality.

We understand the unique challenges and opportunities in the Vietnamese market and can provide tailored solutions to meet your specific requirements. Our team is fluent in both English and Vietnamese, ensuring effective communication and smooth transactions.

Partner with us for all your Polymer needs in Vietnam, and experience the benefits of working with a reliable and trusted supplier. Contact us today for sales inquiries, quotations, or technical support.

Whether you are looking for raw materials for manufacturing, packaging solutions, or specialized Polymer products, we have the knowledge and resources to fulfill your needs. Our technical support team can assist you with product selection, application guidance, and troubleshooting to optimize your processes and enhance product performance.

At CNBM, we prioritize quality and sustainability. We work closely with reputable manufacturers to ensure that our Polymer products meet international standards and comply with environmental regulations. By choosing us as your Polymer supplier in Vietnam, you can trust that you are receiving products of the highest quality.

We understand the unique challenges and opportunities in the Vietnamese market and can provide tailored solutions to meet your specific requirements. Our team is fluent in both English and Vietnamese, ensuring effective communication and smooth transactions.

Partner with us for all your Polymer needs in Vietnam, and experience the benefits of working with a reliable and trusted supplier. Contact us today for sales inquiries, quotations, or technical support.