All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

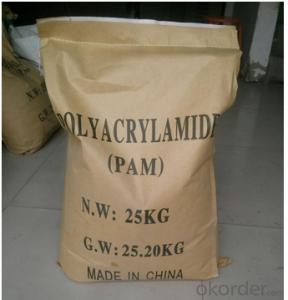

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the key properties of polymers?

The key properties of polymers include their ability to be molded into various shapes, their high strength and durability, their resistance to chemicals and corrosion, their flexibility, and their low density.

What is the role of catalysts in polymer synthesis?

Catalysts in polymer synthesis play a crucial role in speeding up the chemical reactions involved in the formation of polymers. They lower the activation energy required for the reactions to occur, thereby increasing the rate of polymerization. Catalysts also help control the molecular weight and structure of the polymer by influencing the formation of specific bond types and branching patterns. Overall, catalysts enable efficient and controlled polymer synthesis, leading to the desired properties and characteristics of the final polymer product.

How does molecular weight affect the properties of a polymer?

Molecular weight greatly influences the properties of a polymer. Generally, as the molecular weight of a polymer increases, its physical properties like viscosity, melting point, and tensile strength tend to increase as well. This is because higher molecular weight polymers have longer chains, which results in stronger intermolecular forces and greater entanglement. Consequently, higher molecular weight polymers typically exhibit improved mechanical properties and enhanced resistance to degradation.

How does the glass transition temperature affect the behavior of a polymer?

The glass transition temperature significantly influences the behavior of a polymer. Below the glass transition temperature, the polymer is in a glassy state, and it behaves as a rigid and brittle material. Above the glass transition temperature, the polymer becomes soft and rubbery, displaying elastic behavior. The transition temperature affects various polymer properties, such as hardness, flexibility, dimensional stability, and thermal expansion. It also determines the polymer's ability to withstand mechanical stresses and impacts.

Wholesale Polymer from supplier in Sri Lanka

We understand the unique requirements of the Sri Lanka market and strive to meet them by offering a wide range of high-quality Polymer products. Our product range includes polymers for various applications such as packaging, construction, automotive, and electrical industries.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, enabling us to source and deliver Polymer products efficiently and at competitive prices. Whether you are looking for standard or customized Polymer solutions, our team of experts is dedicated to providing you with the best possible options.

In addition to our supply capabilities, we also offer comprehensive technical support to assist you in choosing the right Polymer products for your specific needs. Our experienced team can provide guidance on product selection, application techniques, and troubleshooting, ensuring that you achieve optimal results in your projects.

We take pride in our market development experience in Sri Lanka, which allows us to understand the local market dynamics and trends. This knowledge enables us to offer tailored solutions that meet the specific requirements of your projects and help you stay ahead of the competition.

Partnering with us means gaining access to a reliable and trusted supplier of Polymer products in Sri Lanka. We are committed to delivering exceptional customer service, timely deliveries, and competitive pricing. Contact us today to discuss your Polymer product needs and let us be your preferred partner for all your Polymer requirements in Sri Lanka.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, enabling us to source and deliver Polymer products efficiently and at competitive prices. Whether you are looking for standard or customized Polymer solutions, our team of experts is dedicated to providing you with the best possible options.

In addition to our supply capabilities, we also offer comprehensive technical support to assist you in choosing the right Polymer products for your specific needs. Our experienced team can provide guidance on product selection, application techniques, and troubleshooting, ensuring that you achieve optimal results in your projects.

We take pride in our market development experience in Sri Lanka, which allows us to understand the local market dynamics and trends. This knowledge enables us to offer tailored solutions that meet the specific requirements of your projects and help you stay ahead of the competition.

Partnering with us means gaining access to a reliable and trusted supplier of Polymer products in Sri Lanka. We are committed to delivering exceptional customer service, timely deliveries, and competitive pricing. Contact us today to discuss your Polymer product needs and let us be your preferred partner for all your Polymer requirements in Sri Lanka.

Hot Search

- Fiberglass Chopped Strand in Eritrea

- Fiberglass Mesh Cloth in Portugal

- Composite Pipes in Jordan

- FRP Pultrusion Profiles in Paraguay

- Fiberglass Mat Tissue in Timor Leste

- Fiberglass Fabrics in Mozambique

- Fiberglass Mesh in Australia

- Composite Tank in Bolivia

- Fiberglass Mesh tape in Armenia

- Polymer in South Africa