All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

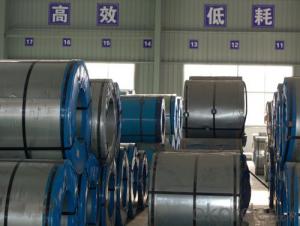

How are steel coils prepared for the manufacturing of industrial and agricultural machinery components?

Steel coils are prepared for the manufacturing of industrial and agricultural machinery components through a series of processes. Firstly, the coils are uncoiled and flattened to achieve the desired thickness and shape. Then, the steel is cut into specific lengths and widths using machines such as shears or slitters. These cut pieces are then further processed through techniques like bending, shaping, and welding to create the necessary components. Finally, the components are thoroughly inspected for quality before being used in the manufacturing process.

What is the significance of coil packaging and banding for transportation in the manufacturing of industrial machinery?

Coil packaging and banding play a crucial role in the transportation of industrial machinery within the manufacturing process. This packaging method ensures that coils, which are commonly used in industrial machinery, are securely bundled and protected during transportation. By banding the coils together, it prevents them from shifting or getting damaged while being transported, ensuring their structural integrity is maintained. This is particularly important in the manufacturing of industrial machinery as any damage to the coils can lead to faulty machinery, delays, and additional costs. Therefore, coil packaging and banding guarantee safe and efficient transportation of industrial machinery, ultimately contributing to the overall quality and success of the manufacturing process.

How are steel coils inspected for surface defects?

Steel coils are inspected for surface defects through visual inspection, where trained personnel carefully examine the coils for any irregularities such as scratches, pits, dents, or discoloration. Additionally, advanced technologies such as automated optical inspection systems can be used to detect and analyze surface defects with high accuracy and efficiency.

Wholesale Steel Coils from supplier in Malta

Our team of experts can guide you through the process of selecting the right Steel Coils for your project, ensuring that you receive the best quality and value for your money. We understand the importance of timely delivery and strive to provide efficient logistics solutions, ensuring that your Steel Coils are delivered to your location in Malta on time.

In addition to our extensive product range, we also offer professional services such as steel coil processing, including cutting, slitting, and shearing. Our state-of-the-art facilities and advanced machinery enable us to handle large volumes of Steel Coils, ensuring quick turnaround times and precise cuts.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources, allowing us to offer competitive prices without compromising on quality. Our strong relationship with manufacturers ensures that we can provide you with the latest and most innovative Steel Coils options in the market.

Customer satisfaction is our top priority, and we strive to exceed your expectations with every interaction. Our team is available to answer any questions you may have, provide technical support, and assist you throughout the procurement process. We pride ourselves on building long-term relationships with our customers, based on trust, reliability, and exceptional service.

Choose us as your preferred Steel Coils supplier in Malta, and let us help you achieve your project goals. Contact us today to discuss your requirements, and we will work closely with you to provide customized solutions that meet your specific needs.

In addition to our extensive product range, we also offer professional services such as steel coil processing, including cutting, slitting, and shearing. Our state-of-the-art facilities and advanced machinery enable us to handle large volumes of Steel Coils, ensuring quick turnaround times and precise cuts.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources, allowing us to offer competitive prices without compromising on quality. Our strong relationship with manufacturers ensures that we can provide you with the latest and most innovative Steel Coils options in the market.

Customer satisfaction is our top priority, and we strive to exceed your expectations with every interaction. Our team is available to answer any questions you may have, provide technical support, and assist you throughout the procurement process. We pride ourselves on building long-term relationships with our customers, based on trust, reliability, and exceptional service.

Choose us as your preferred Steel Coils supplier in Malta, and let us help you achieve your project goals. Contact us today to discuss your requirements, and we will work closely with you to provide customized solutions that meet your specific needs.