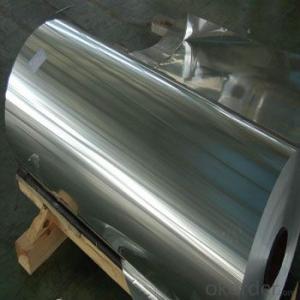

3 4 Aluminum Tubing Coil

3 4 Aluminum Tubing Coil Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For Sale3 4 Aluminum Tubing Coil Supplier & Manufacturer from China

Okorder.com is a professional 3 4 Aluminum Tubing Coil supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 3 4 Aluminum Tubing Coil firm in China.Hot Products

FAQ

- Yes, aluminum coils can be used in the production of electrical transformers. Aluminum coils offer several advantages such as being lighter in weight, having better thermal conductivity, and being more cost-effective compared to traditional copper coils.

- Coil-stucco aluminum coils have a wide range of potential applications due to their unique properties and characteristics. Some of the potential applications of coil-stucco aluminum coils include: 1. Building and construction: Coil-stucco aluminum coils are commonly used in the construction industry for various purposes. They can be used for roofing, cladding, and siding applications, providing durability, versatility, and aesthetic appeal to buildings. The stucco finish on the coils adds texture and enhances the overall appearance of the building. 2. Transportation industry: Coil-stucco aluminum coils are also used in the transportation industry for manufacturing trailers, truck bodies, and other vehicles. Aluminum is lightweight, yet strong, making it an ideal material for reducing the weight of vehicles and increasing fuel efficiency. The stucco finish on the coils provides additional strength and resistance to scratches and abrasions. 3. Appliances and electronics: The coil-stucco aluminum coils are suitable for manufacturing appliances and electronics due to their corrosion resistance and thermal conductivity. Aluminum coils are commonly used in refrigerators, air conditioning units, and other household appliances. The stucco finish provides an added layer of protection against wear and tear. 4. Signage and advertising: Coil-stucco aluminum coils are widely used in the signage and advertising industry for making outdoor signs, billboards, and displays. The stucco finish enhances the visibility of the signs by reducing glare and reflections. Additionally, aluminum is a weather-resistant material, making it suitable for outdoor applications. 5. Packaging industry: Coil-stucco aluminum coils find applications in the packaging industry as well. Aluminum is a non-toxic and non-reactive material, making it suitable for packaging food and beverages. The stucco finish adds an attractive texture to the packaging material, making it visually appealing. 6. Industrial applications: Coil-stucco aluminum coils are used in various industrial applications such as manufacturing equipment, storage tanks, and processing systems. The excellent corrosion resistance, high thermal conductivity, and strength make aluminum coils a preferred choice in industries where these properties are crucial. Overall, the potential applications of coil-stucco aluminum coils are diverse and extensive. The unique properties of aluminum, combined with the stucco finish, make these coils suitable for a wide range of industries, including construction, transportation, appliances, signage, packaging, and industrial applications.

- show step by step

- First write out the formula reaction: 4Al + 3O2 --- 2Al2O3 Next, find the number of moles of oxygen gas needed to oxidize 3.42 g of aluminium completely. From the cchemical equation above, 3 mol of oxygen is used to oxidize completely 4 mol of aluminium. Calculate the no. of moles of aluminium used: no. of moles of aluminium used = 3.42 g / molar mass of Al = 3.42 g / 26.98 g mol^-1 = 0.127 mol Use the mole ratio concept to find the no. of moles of oxygen required: no. of moles of oxygen required : no. of moles of aluminium used = 3 : 4 no. of moles of oxygen required / 0.127 = 3 / 4 no. of moles of oxygen required = (3 / 4)(0.127) = 0.095 mol Next, use the gas equation PV = nRT [P: Pressure of gas in Pa; V: Volume of gas in m^3; n: no. of moles; R, gas constant, 8.314 J mol^-1 K^-1; T, Temperature of gas in K] -Convert 0.975 atm to Pa: 0.975 atm = (0.975 x 101325) Pa = 98791.875 Pa -Convert 25 oC to K: 25 oC = (25 + 273) K = 298 K -Substitute into the equation PV = nRT and solve it: (98791.875)(V) = (0.095)(8.31)(298) (98791.875)(V) = 235.2561 V = 235.2561 / 98791.875 = 0.002381 m^3 = (0.002381 x 10^3) L = 2.381 L

- How can aluminium ingots be processed into aluminium coils (aluminium sheets)?

- Make the blank first, then roll on the mill.

- Is there any elements that can be added to aluminum to create any compound?

- Which industries? while you're actually not greater particular the checklist can pass on perpetually. i'm going to checklist some nonetheless: Hydrogen-Used to make ammonia and for hydrogenation techniques like the production of liquid fuels and margarine. Ammonia-Used to make fertilizer for agriculture. Sulfuric acid-fabric ending, prescribed drugs, pesticides, oil-nicely acidification, preserving coatings, purification of petrol, manufacture of detergents, explosives....... Carbon-Used for all smelting of metals Iron-For the production of steel. Oxygen-Steelmaking, paint pigment, welding, rocket gas. As you may locate the checklist is getting ridiculous. Sulfuric acid is the main used yet you may look this info up in any good inorganic chemistry textbook.

- Can the displacement sensor be used for real-time measurement of the aluminum coil thickness?

- You are suggested to use eddy current displacement sensor KD2306 to measure aluminum.

- Aluminum coils are essential components in energy-efficient lighting systems due to their unique properties and functionalities. Firstly, aluminum is an excellent conductor of electricity, allowing for efficient energy flow within the lighting system. This property ensures that minimal energy is lost during transmission, maximizing the overall energy efficiency of the system. Moreover, aluminum coils are lightweight and durable, making them ideal for use in lighting systems. The lightweight nature of aluminum allows for easier installation and handling, reducing the overall energy required during the manufacturing and installation processes. Additionally, aluminum's durability ensures that the coils can withstand the rigors of daily use without compromising performance, further contributing to the longevity and efficiency of the lighting system. Furthermore, aluminum has excellent thermal conductivity, allowing for efficient heat dissipation. Heat management is crucial in lighting systems as excessive heat can reduce the lifespan and efficiency of the bulbs. By using aluminum coils, the heat generated by the lighting system can be effectively dispersed, minimizing the risk of overheating and ensuring optimal performance. In summary, aluminum coils contribute to energy-efficient lighting systems by providing efficient electrical conductivity, lightweight and durable construction, and effective heat dissipation. These properties help to minimize energy loss, reduce manufacturing and installation energy requirements, and enhance the overall efficiency and longevity of the lighting system.

- Automotive heat shields can indeed utilize aluminum coils. Aluminum, known for its outstanding thermal conductivity and high melting point, is frequently employed as a heat shield material. Its lightweight nature and remarkable resistance to corrosion make it particularly well-suited for automotive purposes. By effortlessly molding aluminum coils into the desired configuration, effective heat insulation can be attained, safeguarding delicate components from the engine or exhaust system's excessive heat. Moreover, aluminum is cost-efficient and easily accessible, contributing to its widespread preference as an automotive heat shield material.