WPC Decking Wood Plastic Composite Anti-water, Anti-insect, Rigidity

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

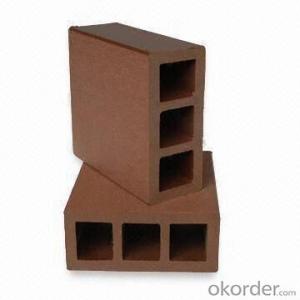

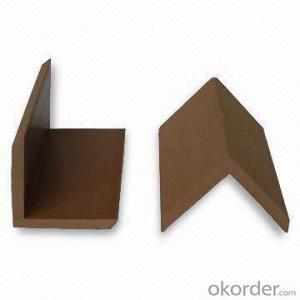

Structure of WPC Decking :

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

Description Main Features of the WPC Decking:

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

indoor wpc flooring

deck wpc solid

WPC Decking Images:

WPC Decking Specicication:

FAQ of WPC Decking :

1> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

2> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

3> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

4> How to buy and concerned terms?

*MOQ – 300m2 per item

*Lead time—2 weeks

*Departure port—Shanghai

*Package-- PE film, carton box or 2pcs.bundle, treated pallet

5> Certificates and Quality guarantee

*Certificates – CE&ISO 9001 complied

*Warranty—10 years

*Quality guarantee—test report for each order under the strict management system.

6> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

- Q:In the old composite wood flooring and then add a layer of elephant composite wood flooring is possible, will not exceed the formaldehyde content

- Any brand of any floor will contain formaldehyde, formaldehyde not only from the glue, but also from the paint. Formaldehyde emission in accordance with national enforcement standards is 1.5mg / L, better than this standard Caixing. Decoration process, you can release a lot of formaldehyde things, such as home, carpentry, paint ... ... it is inevitable to ensure that the standard. You can ask the business, floor production is used in what glue, such as water-based glue and the like. General water-based plastic market price in 2000 or so a ton, and professional floor glue about one ton, such as the international market more professional floor glue is Finland's Tail glue. And paint, then, relatively good is the German Fu Fu paint.

- Q:engineered floor toronto?

- What about it? Engineered wood is available any where flooring is sold. GL

- Q:A square 80 yuan floor budget, with a composite wood floor or a large tiles good? Please introduce the brand

- Choose a composite floor bar Floor tiles, where the cement and sand materials and paving the cost of artificial waste after the remaining 60 yuan, and 60 yuan per flat tiles can only buy low-grade tiles, color and specifications do not have much choice. And tiles of different wall tiles must also be durable and not fade but low-grade brick is difficult to meet the quality requirements. Select the composite floor of the substrate to consider the substrate is better, the election is a large sub-substrate to do the quality of the composite floor can be, and not necessarily selected brand, first asked the supplier floor substrate.

- Q:My home is used: Montblanc Teng map of the floor, renovation is less than two months began to drums, there are more than a dozen, looking for after-sales service providers, he said that is engaged in the infiltration of lying lie, Run by water. I do not understand, we engage in cleaning are the first wiping the damp, and then wring dry, if you do so on the drum package, how to do after cleaning? Is there a problem with the quality of the floor? Please enlighten the Supreme more

- First, the composite floor drum package approach: 1, weight and waxing method. Floor seams at the small area of the Alice, can be used in heavy pressure on the above, after a period of time after the wood floor will return to normal; after the pressure of the floor can be waxing, waxing after the bubble floor will be basically the same as the original Few. 2, re-pavement; 3, for the floor. Second, the floor will be inflated after the damp, the floor has no room around the expansion of the space so drum up, and a long time the floor will be deformed.

- Q:Now the home of the composite floor ~ how much the general price ~ ~ ~ ~ ~ ~ ~ more

- Composite floor wood composite with enhanced composite, solid wood composite is generally 1.2cm thick, strengthen the general 0.8 thick, solid wood flooring a little more than 100 points, strengthen the composite a little better 7,80, 70 the best do not use the following, quality assurance can not.

- Q:Are not laminate flooring environmentally friendly?

- Can not say that is not environmentally friendly, but relatively speaking: solid wood composite floor is indeed enhanced than the composite floor laminate laminate laminate laminate laminate flooring by the wear-resistant layer, decorative layer, grass-roots, balanced layer composition. Advantages are wear-resistant: about 10 to 30 times the ordinary paint floor of the floor; beautiful: available computer simulation of a variety of wood grain and pattern, color; stability: completely broke the original wood organization, destroyed anisotropy and Wet expansion and contraction characteristics, the size is very stable, especially for the warm room to the room. Advantages Wear: about 10 to 30 times more than ordinary paint floor. Beautiful: available computer simulation of a variety of grain and pattern, color. Stable: completely break the original wood of the organization, destruction of the anisotropy and wet expansion and contraction characteristics, the size is very stable, especially for the floor to warm the room. In addition, there are impact, anti-static, resistant to pollution, light resistance, resistance to burning cigarettes, easy installation, maintenance and simple. Disadvantages of blisters can not be damaged after damage, foot feeling poor. In particular, it is pointed out that there have been dealers in the past that strengthen the composite floor is "waterproof floor", which is only for the surface, in fact, strengthen the use of composite flooring only to avoid the blisters.

- Q:Why is the solid wood flooring more expensive than the composite floor ah?

- My home decoration complex floor less than a year, there are several computer desk has been blistering. It may be better for solid wood flooring.

- Q:What kind of solid wood flooring? Which is better?

- 1. Three layers of solid wood flooring for the top of the table, are selected high-quality tree species. The middle layer for the core board, the general selection of pine because the pine has a good stability. The lower floor for the main plate to poplar, The three layers of the texture between the two vertical and horizontal, that is, criss-cross. This process is to ensure the stability of the floor .2 multi-layer solid wood flooring is divided into two parts, the top of the table and the underlying substrate. The number of layers of the substrate depends on the design thickness of the floor, and each layer of the multi-layer solid wood flooring is a criss-cross structure between the layers and the layers, so that the internal stress causing the deformation of the wood is canceled off Solid wood flooring is the most reliable stability of solid wood flooring

- Q:Or solid wood (also see what the wood, such as two-winged beans, etc.), but the composite price is better, not easy to change, good care.

- It is recommended to remove the original floor, and then re-install the new floor. There are several reasons for the following reasons. 1, environmental protection: even if the special green sheet, there are formaldehyde. If blindly superimposed artificial plate, plant Shan class to catch the non-stumbling stone leopard will be excessive. 2, for the floor is certainly not satisfied with the original floor, and perhaps just did not fancy color. But does not rule out the place where there are wear and damage, these places if covered under the new floor, easy to absorb moisture deformation, affecting the installation and use of the new floor effect. 3, because it is the old house, it is best to be able to remove the old floor, you can thoroughly clean. And can look at the original ground conditions, is not needed from the new ground flat. 4, the old floor to install a new floor, due to elevation, it is likely to cause the gap under the gap. Or other aspects of the relevant decorative items modified.

- Q:My house up and down the floor of the water there is not much water above the floor there is water just started with the foot of the wall on the edge of the wall will have water overflow from the wall after an hour after the top of the skeleton repair Lennon agent Yi Chuan floor now basically no It is estimated that the penetration of the floor has been in the first time to open the door to open the door which the Supreme who knows the floor will be deformed? Can not use it? Do not open? Is the best professional answer more

- First of all to be able to deal with the water first clean, the floor of the water for the time being to ignore it, the floor is the main water to keep the ventilation to make it natural dry, if the top of the skeleton repair Lennon agent Wang Chuan floor is removed, the floor But will be deformed, in order to let the floor as soon as possible, you can remove the buckle, the baseboard if it is easy to remove the water can be evaporated as soon as possible.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WPC Decking Wood Plastic Composite Anti-water, Anti-insect, Rigidity

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords