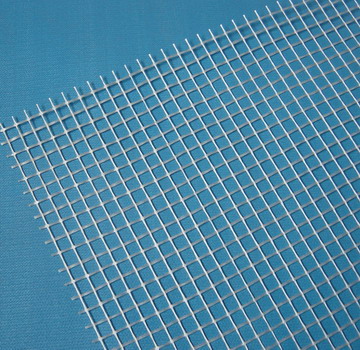

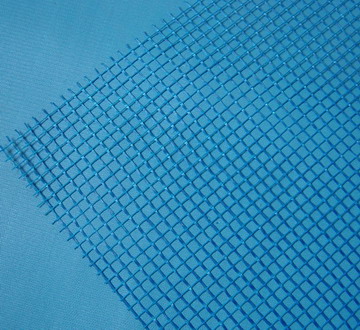

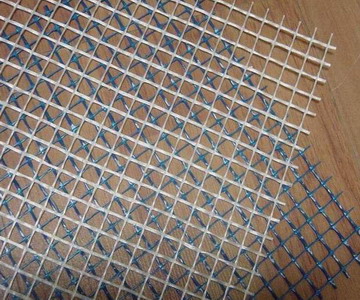

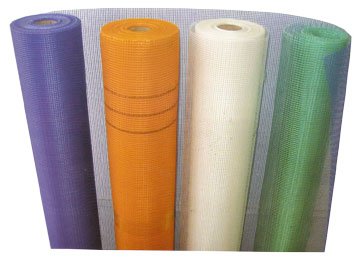

Woven black line for the fiberglass From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 4000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Packaging & Delivery

| Packaging Details: | Each roll packing with polybag and then in carton . we accept customer's special packing. |

| Delivery Detail: | 45days |

Woven black line on both sides for the fiberglass based on your requirement onetouch and expresstouch and express

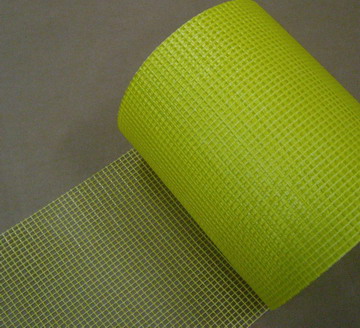

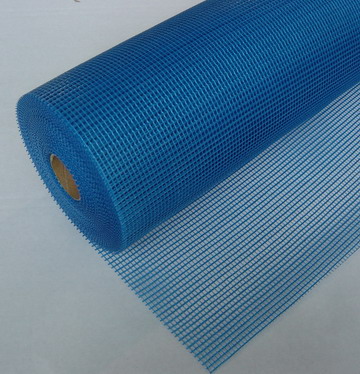

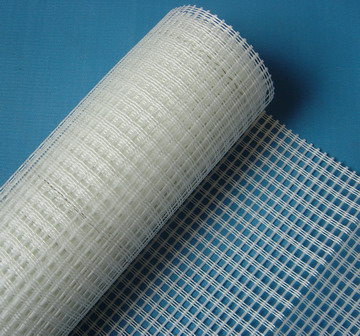

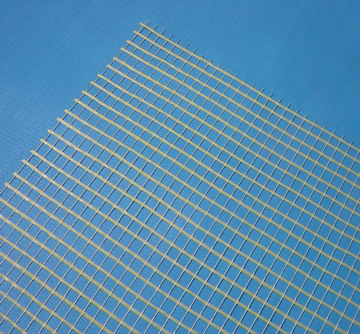

Fiberglass gridding mesh is based on the alkali or alkali-free glass fiber woven fabrics, based coating formed by the alkali. The product is high strength, good paste, clothing stickers, positioning of the excellent, widely used in wall enhancement, wall insulation, roofing, etc., can also be used in cement, plastics, asphalt, marble, mosaic wall materials increased, the construction industry an ideal engineering materia

Specifications

glass fiber mesh

Model No.:STDM-1N

Size:1m*50m/roll

Zirconium Content : 0% ~16.5%

Each roll packing with polybag,

30 rolls/carton

Woven black line on both sides 5cm of the longitudinal position

Horizontal interval 1 m to print black line

Fiberglass Mesh is on the basic of fiberglass woven fabric, after surface treatment, this alkali-resistant mesh has excellent properties including water-resistance, alkali-resistance, flexibility, softness, and resistance to aging. It is widely used for waterproofing in roofing applications, reinforcement for natural marble, plaster board, artificial and Exterior Insulation Finishing System(EIFS).

Techinical Data

CSM | Glass Type | Binder type | Density | Roll weight | Width |

EMC225

| E-glass | Powder/Emulsion | 225g/m2 | 30-60KG | ≤3300mm |

EMC300 | E-glass | Powder/Emulsion | 300g/m2 | 30-60KG | ≤3300mm |

EMC450 | E-glass | Powder/Emulsion | 450g/m2 | 30-60KG | ≤3300mm |

EMC600 | E-glass | Powder/Emulsion | 600g/m2 | 30-60KG | ≤3300mm |

CMC225 | C-glass | Powder/Emulsion | 225g/m2 | 30-60KG | ≤3300mm |

CMC300 | C-glass | Powder/Emulsion | 300g/m2 | 30-60KG | ≤3300mm |

CMC450 | C-glass | Powder/Emulsion | 450g/m2 | 30-60KG | ≤3300mm |

CMC600 | C-glass | Powder/Emulsion | 600g/m2 | 30-60KG | ≤3300mm |

- Q:Logs, lumber (square wood, plate, specifications) from what kind of tree species, what characteristics, mainly used for what type of wood structure, the specification is how to grade?

- Why is the Dushui River Particleboard so popular? Lu Shuihe plate is the main raw material of pine, due to a single tree species, pine stability is also very good, so the plate of the process indicators are very good. Lu Shuihe Particleboard from the appearance of observation, flat surface, uniform color, plate cut side of the shavings distributed evenly, strong, the board has a slight wood flavor, no irritating smell, all products are in line with European environmental standards. As the saying goes, "wine is not afraid of alley deep." "Lushui River" is the buyer to buy, but also sellers of the selling point, such products certainly do not worry about selling.

- Q:What is the board made of the board?

- Particleboard: Jilin forest workers Lushui River plate No release of formaldehyde "love home plate" licensed! The The These are the lacquer, are to reach the national standard! Is now the market commonly used plate!

- Q:Is Qu Mei 's sheet green?

- Hello, I am pleased to answer for you, the plate can be used directly to fish, seen in the store, a friend home decoration is the song home custom home, very good, hope to help you

- Q:Bookcase with what the best plate

- It is best to use a fir fingerboard for a bookcase and a wardrobe. Environmental protection and beautiful, direct brush on the varnish, very kind of living in the pastoral fresh gas. But there is little change that is. Wardrobe doors need to use woodworking board or three-layer composite finger plate to do. And the bare part of the backplate is reinforced with white pine keel. This will avoid cracking. Another kind of cracking may refer to the board failure, moisture content is relatively high. Therefore, it is recommended that you use a good quality plate, home improvement commonly used brands are Moganshan and bunny. You can also use Jiangxi 100 source. The quality of the king coconut is not evaluated. I wish you a pleasant decoration.

- Q:Look at the brand of wardrobe quite nice but offer too high. So I would like to buy their own plate to find wood workers to do. What sheet is good?

- I suggest you use the ecological board, if you want to paint can be in the ecological board to pay a layer of 0.3cm outside the density board, wardrobe backplane with 0.3cm ecological board on the line, and you have to prepare the edge (in the buy When the ecological board and the ecological board color of the same edge of the edge), the pipe hinge, do drawer with the track, drawer lock, the door suggested that you use sliding doors, because the wooden doors do manually because the span is too large, easy Deformation, the other is to use the nails, and you can let the woodworking master to give you a single material, one-time purchase Qi.

- Q:What conditions do you need? The The Its general 2-story cost is? The The Size needs to be the kind of foreign people to live !!! in Xi'an where to facilitate the purchase of materials? The The I need professional answers!

- Disadvantages: Wooden houses need to deal with anti-corrosion processes. In the earthquake, moisture, fire, insulation and other aspects of short board.

- Q:Decoration need to buy snow Ling plate, the plate how?

- Snow surface plate product shape flat, thick and large ratio, the unit volume of the surface area is also great, this shape features to bring its use on the characteristics: (1) surface area, so inclusive capacity, in the chemical, container, construction (2) can be arbitrarily tailored, bending, stamping, welding, made of various components of the product, the use of flexible and convenient, in the automotive, aviation, shipbuilding and tractor manufacturing and other sectors occupy a very large number of metal products, metal products, metal structure, Important position; (3) can be bent, welded into various types of complex sections of steel, steel, large I-beam, channel and other structural parts, it is called "universal steel."

- Q:Pc plate and memory board comparison, which is good?

- PC board is a polycarbonate as the main component, the use of co-extrusion technology CO-EXTRUSION made of a high-quality sheet. Because of its surface covered with a layer of high concentration of UV absorbers, in addition to the characteristics of anti-ultraviolet and can maintain long-term weather, never fade. Memory plate toughness is relatively large. Select these two plates according to your needs.

- Q:Loft shop what board is good

- Loft furniture generally should not be purchased, should be tailored by the designer. Usually small chic mainly, the furniture preferred simple lines, frame type of furniture, in the local, you can match the more bright colors than the jumping of the accessories or some interesting relatively strong furniture. The attic floor depends on the loft's functional area. Such as as a private space or children's room, most of the use of desktop, so comfortable better. As for the top treatment, it is more complex, but also the focus of decorative design, usually, the use of natural natural wood decoration. In addition, due to the loft structure constraints, designers need to visually make the space becomes larger and larger, while the characteristics of the structure itself to produce a kind of architectural structure of the United States, this beauty needs consistent with the style of the room, it is necessary to follow the modern Concise, against the extra decoration, but also to meet the comfort and beauty of the attic lighting generally bad, so the color should be bright and mainly. This can make the attic seem more bright and transparent, to make up for deficiencies. In addition, because the attic is generally not flat top, and there are many tops are relatively high, the choice of lights is very important. You can choose some of the distinctive chandeliers, can also play a decorative role, but the shortcomings of the chandelier is a light problem, maintenance is not convenient, therefore, you can also use the wall lamp and floor lamp, which in double Light is better

- Q:How is the rich forest plate? What about environmental performance?

- This brand did not really heard of my home agent is a forest brand plate, Guangdong OKorder brand

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Woven black line for the fiberglass From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 4000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords