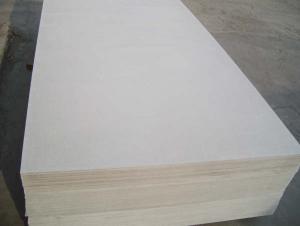

Fiber cement board price/fire resistance fiber cement board/wood grain fiber cement board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Size | 1220x2400mm |

| Thickness | 4mm,4.5mm,5mm,6mm,8mm,10mm,12mm |

| Surface | Rough side,smooth side,sanding side |

| Remark | Other special size canbe made by the customer's requirement |

| Usage | interior/exterior Partition,Ceiling,outwall decoration... |

| Process | 1. High density fiber cement board as substrate. 2. UV painting on the surface, Glossy and Matt for Every Pattern. |

| MOQ | 2x20GP for each thickness |

| Payment Terms | 30% prepayment, balance within 10 days of the signed B/L |

| Packaging | Pallet packaging |

| Port | Qingdao |

| Supply Ability | 100000 M2/day |

| Spec | Test data | Inspection basis |

| Density | 1.34g/cm3 | GB/T7019~1997 |

| Dry state bending strength | 11MPa | GB/T7019~1997 |

| Water saturation state bending strength | 10MPa | GB/T7019~1997 |

| Bulking factor | 0.2% | JC688~2006 |

| Formaldehyde release | <0.1mg/L(qualified) | GB18580~2001 |

| Activity coefficient | qualified | GB6566~2001 |

| Combustibility | A1 Level | GB/T5464~1999 |

| Moisture absorption | 0.12% | GA 160~2004 |

| Impermeability | no water drop at the buttom | GA 160~2004 |

| Contract with dry rate | 0.1 | JC688~2006 |

| Thermal Conductivity | 0.117kca/mhC | JC/T5641~2008 |

The waytoctu and construct the fiber cement board is the same as the calcium silicate board!Use self tapping screw to fixed on the keel,after put joint mixture on the gap in between ,if you use the fiber cement board in washing room or other places where are wet or contains water,it should be reinforce the waterproof to ensure the entire waterproofing system!

Fiber cement board Application

Used for ceiling, interior/exterior partition and outer wall decoration etc.Such as Business building, Entertainment facility, supermarket, hotel & restaurant, factory, warehouse, apartment building, hospital, theater and station etc.

- Q:What are the environmental ratings of the board?

- E0 E1 E2 GB The domestic market is more common E0 and E1 can be used directly for home decoration E0 more expensive than the general choice of E1 more

- Q:Plate Jianxiang E0 and ecological board which is good

- This is the concept of two issues, it is recommended that you choose Jianxiang sheet EO ecological board. Ecological board in the industry there are a variety of names, commonly known as a paint-free board and melamine board. The initial name is called melamine board, but because of China's dairy products pollution incident, and later was renamed, the industry collectively referred to as the paint-free board, also called the ecological board, but the ecological board is too general, because many of the eco-friendly sheet can also Called the ecological board, so easy to confuse. EO, E1 is the content of formaldehyde content of sheet metal standard, all kinds of sheet metal formaldehyde emission standards.

- Q:KT board is what plate ah? Generally used in where the best picture to explain do not copy copy! To be original

- One, KT board 1, KT board is a kind of PS particles from the foam generated by the core plate, after the surface of the film made of a new type of material, the board stiff, light, not perishable, easy to process, and can be directly on the board wire Printing (silk screen), paint (need to detect paint adaptability), mounted on the gum screen and inkjet, widely used in advertising display promotions, architectural decoration, culture and art and packaging and so on. The use of advertising is used for product promotion information dissemination of the exhibition, display and notice with mounting liner, the other is a large number of applications used in a screen printing, especially for a wide range of unified publicity activities. 2, kt board according to the production process can be divided into cold composite and thermal composite, in addition to plastic cardboard is one of them, but mostly for indoor advertising, the basic requirements must ensure that no blistering and deformation. At present there is an improved in the market kt plastic cardboard, with a special combination of paper and core cold, can not be in a long time without deformation.

- Q:There are other (some of which are granite): black sands, black and white roots, purple rosewood, green diamond, blue diamond, gold flower stone, beige series, large green flowers, elegant white, jazz white, sesame white and so on. Common thickness is generally 12mm, 15mm, 18mm, 20mm, 22mm, 25mm, 30mm.

- Above the man, said very professional, very comprehensive, stone is roughly divided into granite, marble, sandstone,

- Q:Q235 sheet of the label

- Marked as: 3 * Q235 got it, * is multiplied ah! Or in the view where the steel plate indicates t = 3 or t3 too!

- Q:See a lot of people with black frame, comfortable?

- The most common: metal, sheet, pure titanium, solid wood, TR90 Now the glasses frame whether the brand or frame color or the production of materials are varied. A pair of beautiful glasses is not only beautiful appearance, but also need to know when the wearer face and glasses with how to match, so that the more perfect, glasses will play its role in the modification, so you more attractive. Here to understand what glasses look good. Black box glasses. Black-rimmed glasses to wear after the arts Van special thick, and personal temperament will be changed, so that the current market is particularly popular. Black-rimmed glasses to wear, the more prominent personal contours and the overall personal characteristics, therefore, wearing black-rimmed glasses, then in addition to the appropriate face and color, wearing dress and eye makeup are very important, such as Zhao Wei wearing black box glasses , Highlighting the side with a round black frame brought by the charm, simple atmosphere, and its own unique atmosphere is very strong. Today's sheet glasses can be described as all kinds of people are particularly fond of the work complex and delicate, diverse styles, it is important that the color is good, not allergic, it is not easy to fade, it can be wild, itself is in the high-end frame. Whether it is from their own grades or style design is very advantages, and many brands of glasses are made of sheet metal, such as by the industry more appreciated Levi's frame, is used to produce high-grade sheet, beautiful appearance, Wearing fashion is also very good. What glasses are good-looking? Each pair of glasses have their own characteristics, have their own bright spots, a reasonable choice, the correct match, after wearing are generally very good. Moreover, the spectacle frame itself is an ornament, plays the role of landscaping. Domestic brands can consider the trend of the brand "wood ninety", a physical store.

- Q:What are the characteristics of KRD blue epoxy sheet?

- "KRD blue epoxy plate" in 1938 by the German company in Switzerland patent application in Switzerland, 1946 secretly put into operation in the high-end military plate, in 2008 Germany Kerui De company in the original epoxy board formula based on improved by adding KRD blue Water resistant weather factor, to produce high-end "KRD blue epoxy plate", put the German market, mainly used in luxury cruise ships and high-end cars and high-end interior furniture production. October 2009 European style (Hong Kong) bathroom International Development Co., Ltd. formally introduced "KRD blue epoxy plate" production line into the civilian bathroom furniture production. ????"KRD blue epoxy sheet" has a strong chemical resistance and water resistance. In the curing system of ether, benzene ring and fatty hydroxyl is not susceptible to acid and alkali erosion. Can be used for two years in seawater, petroleum, kerosene, 10% H2SO4, 10% HCl, 10% HAc, 10% NH3, 10% H3PO4 and 30% Na2CO3, and half a year at 50% H2SO4 and 10% HNO3; % NaOH (100 ° C) for a month or soaked in fresh water for 50 years, the performance remains the same. ????"KRD blue epoxy plate" molecular chain structure contains two or more epoxy groups of polymer compounds, process performance is good, strong nail holding force, product size and stability, no radiation, zero formaldehyde, is the current The forefront of the international environmental health, strong weather resistance of high-end furniture preferred plate. "KRD blue epoxy plate" Appearance features: A high density light B The appearance of the plate is light blue C strong flexibility

- Q:What kind of wood is the water-based material? Environmental protection?

- Water-based days is a professional engaged in water-based polymer research and application of high-tech enterprises. "Water-based technology, beautiful China" for the corporate mission, with the world's first water-based wet synthetic leather production line, China's first 100,000 tons of water-based polyurethane production line and China's first harmful chemical substances testing center. Water-based science days not only to create a new era of non-toxic home improvement, but also to promote water-based materials, furniture, synthetic leather and other areas of green environmental protection industry changes.

- Q:My family bought a cupboard made of melamine board these, a week or after the taste? These taste has no harm? Is there a methanol? Is it good to use these furniture?

- Melamine board, also known as double decorative panels, paint panels, ecological board, it was called a molding board. Its substrate is also particleboard and MDF, made by the substrate and the surface bonding, the surface veneer mainly domestic and imported two categories, because it is after the fire, anti-wear, waterproof soaking treatment, the use of results Similar to the composite wood flooring. Melamine decorative board performance: 1, can be any imitation of a variety of patterns, bright color, for a variety of wood-based panels and wood veneer, hardness, wear resistance, good heat resistance. 2, chemical resistance in general, can resist the general acid, alkali, grease and alcohol and other solvent wear. 3, the surface smooth and smooth, easy to maintain cleaning. Melamine board with natural wood can not both the excellent performance, it is often used for indoor construction and a variety of furniture, cabinets on the decoration. Melamine board is a wall decoration material. Some people use melamine board counterfeit flooring for floor decoration, which is not appropriate. Common specifications: 2440mm × 1220mm, thickness 1.5-1.8Cm.

- Q:Shang material home furnishings with the plate is what material

- Shangpin furniture with furniture is a medium density fiberboard, formaldehyde content is far lower than the national E1 level standards, the relevant standards close to the European E0 level standards. Plate furniture environmental protection, wear resistance, fire resistance, acid and alkali are higher than the traditional solid wood furniture: 1. Environmental protection: good plate furniture used for the quality of the substrate for the high-quality wood, the use of high environmental protection and glue with less, mainly by high-pressure raw materials forming a surface of the use of environmentally friendly melamine fire materials, without any volatile Gas release. Solid wood furniture surface is sprayed with colored paint, and paint is containing formaldehyde, benzene and other harmful gases, any kind of paint contains these harmful gases, but how much of the problem. Poor solid wood furniture is the use of non-compliance of the paint, the production of some of the furniture with a few years there are obvious irritating smell. 2. Wear resistance: melamine resin is a very high hardness of the material, the general metal will not leave scratches in the above, and paint is a soft texture of the material, it is easy to draw flowers, not wear. 3. Fire: melamine resin itself is a fireproof material, do not help combustion. The paint is a kind of easy to burn the material, not fire. 4. Acid and alkali resistance: melamine resin has a certain acid and alkali resistance, the general acid and alkali will not damage its surface. The physical properties of the paint are not very stable easily by acid-base burns, loss of surface brightness or even stripping.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber cement board price/fire resistance fiber cement board/wood grain fiber cement board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords