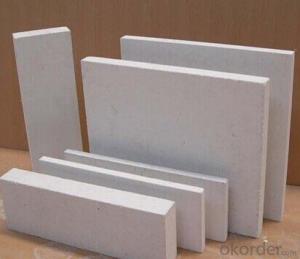

Magnesium Oxide Fireproof Board (mgo board) Europe Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

2) Swelling rate: 0.34%

3) Heating contraction: 1.2%

4) Density: 0.95-1.1g/cm3

5) Dry bending resistance: 16Mpa

6) Sound insulation: 44 dB

7) Heat-transfer coefficient: 0.14w/mk

8) Environmental friendly: Free of asbestos, formaldehyde and ammoni

Using places:

DESCRIPTION

Magnesium oxide board is made from Magnesium Oxide(MgO), Magnesium Chloride(Mgcl2), fiberglass mesh, sawdust, perlite etc.,using highly purified active MgO as the main fireproof material of board, high-quality MgCl2 as the main cementing material to solidify other materials, alkali-resistance fiberglass mesh to ensure the high strength of board, soft sawdust and light non-combustible perlite as filling materials. It is a kind of Eco-friendly fireproof board widely used in construction and decoration.

(Pave slurry on the surface of MGO board to reduce the holes, make the surface more smoothness and less holes. Slurry paved board is a kind building material to further process.Suit to stick thin decorative material or paint on the board.)

- Q:The advantages and disadvantages of the plate frame, what brand is better?

- Plate life is longer, unlike the metal easy to aging corrosion, color shape can also be done beautiful point, The disadvantage is that can not do the memory of metal as ultra-light style, so not suitable for small friends face. I am wearing a holy Paul, I feel pretty good

- Q:What is the board made of the board?

- Particleboard: Jilin forest workers Lushui River plate No release of formaldehyde "love home plate" licensed! The The These are the lacquer, are to reach the national standard! Is now the market commonly used plate!

- Q:Now home furnishings are what plate?

- Plywood splint, also known as plywood, line known as fine core board. Made of three or more layers of one millimeter thick veneer or sheet adhesive. Is the most commonly used furniture handmade furniture. Plywood is generally divided into 3 PCT board, 5 PCT board, 9 PCT board, 12 PCT board, 15 PCT board and 18 PCT board six specifications (1 PCT is 1mm).

- Q:In addition to the optical shop can have a special person will help you tune, of course, is generally selling glasses.

- 1, if the nose is a metal support, you can hand to the middle of breaking off. 2, if the whole into a whole is plastic, nasal care will not be deformed. It must be attached to the lens and the lens between the screws too loose, two mirror feet breaking too open, you can tighten the screw tight. But the screw is very small, it is recommended to the optical shop told him to help you twisted. Adjust the cleaning and repair nose care such things all stores will do for you free of charge. You can go to your original optical shop, but casually a RP shop staff will be happy to help you tune and clean up.

- Q:How to degrease the wood

- Vacuum drying method The vacuum drying method is a method in which wood is piled up in a closed container and dried at a lower pressure than atmospheric pressure to remove part of the resin, and vacuum drying is suitable for wood having good air permeability. Vacuum drying method, can not achieve the desired effect. Vacuum drying is mainly characterized by drying faster than other methods, compared with other drying methods, drying time can be shortened about 25 ~ 1 2. Japan's Naito Truth [4] Drying of Douglas fir wood by high-frequency vacuum drying is considered to be effective for degreasing and mainly in the early stages of drying, since the moisture removal in the wood is in the early stages of drying, so its degreasing action is also in the early stages of drying. ] And other larch wood for cooking, vacuum and artificial drying, that cooking, vacuum degreasing effect is good, because the cooking to increase the permeability of wood.If the cooking, vacuum drying after artificial drying degreasing effect is better, because the vacuum drying Shorten the drying time.But the vacuum drying equipment is complex, the investment is high, there are vacuum drying machine manufacturers can use this method.To generally improve the degreasing effect, often using two or more degreasing method combination, such as Liquid immersion plus steam drying, pharmacy impregnation vacuum, steam vacuum pressure vacuum and other methods. The manufacturer can be based on the actual situation of the factory, choose the appropriate method for their own.

- Q:Will the sheet metal processing bending coefficient and plate thickness, bending angle, bending radius is what is the relationship between the urgent!

- The bending factor and the thickness of the material you said bending angle ah bend the radius and bending the bending machine up and down mold, the length of the bending parts are related We are using experience value. After all, conventional standard brick algorithm does not take into account the equipment wear and tear, sheet material thickness of the situation Different thickness determines the different bending factors such as 1mm cold rolling fold 90 degrees and 2mm cold rolling fold 90 degrees Our actual situation is 1mm coefficient is 1.8 2mm coefficient is 3.5 The same angle 90 degrees is a bending factor of 60 degrees is 1/2 of the bending coefficient of 45 degrees is 1/3 of the bending coefficient of less than 30 degrees according to the different thickness of the buckle or buckle a 0.5 Material and plate thickness as different materials, the bending coefficient is different The bending radius is related to the bending machine. The standard single V or double V is even the default value of the other V slots. But there are customers who need to be too small or a large bend radius will be specific to the analysis Too small bend radius, our approach is to plan the groove to bend, so that the bending radius is very small, almost vertical right angle bending Too large bending radius, the upper mold can be used on the corresponding arc on the mold (note that the upper arc of the R is the inside of your bending R, if the outside R according to the outer R minus a plate thickness to determine the model) Or a large R30 50 or more, you can use a split bend, which requires the calculation of the cut-in angle and the last knife angle, as well as the size and angle of each knife There is a part of the length of this I think a lot or machine equipment and related to our machine a long time 1.5mm stainless steel over 1m according to the case will not use 8mm mold bending

- Q:I am looking for woodworking furniture, what kind of wood is not easy to deformation, wood prices? Thank you!

- On the north, the oak splicing board is the best election, 18 of the plate about 270 yuan a bar it Followed by pine, in the north of the larger temperature, easy to deformation, stability, poor. These are high-end, mid-range is the joinery board, and stability is better, but the effect in general. Low-grade is Aosha Sakamoto, particleboard, etc., should be processed, but the life is shorter.

- Q:Malacca plate true and false how to identify

- Malacca plate true and false identification methods are as follows: 1, there is no taste in the processing process: Malacca ecological board if there is no pungent taste, is false ecological board. Because the material is Malacca, and Malacca would have a taste, but the taste is the tree itself comes and is described as harmless. 2, if the substrate is too hard to note: the substrate is too fake eco-board, Malacca plate is soft, easy to deformation. 3, Edge of the problem, Malacca ecological board if there are unpleasant, there is a flattening phenomenon, the ecological board itself is a problem. Although Malacca is softer, good Malacca ecological board will not appear edge flattening phenomenon. Malacca core board, the use of Malacca wood processing and production of man-made sheet, are semi-finished products. While the Malacca sheet is the use of this material core plate made of finished sheet. High quality Malacca wood, with colorful, strong texture, texture clear, colorful and other advantages, because of its wood properties, Malacca plate color expression than any kind of wood grain. Malacca ecological sheet, but also take into account the wear resistance, scratch resistance, corrosion resistance, anti-aging, excellent flame retardant properties, even after the damp air will not be deformed, the quality is always new.

- Q:E0 grade sheet and E1 grade plate, which is more environmentally friendly? How to distinguish

- E0 level is the European standard, e1 level is the domestic standard, e0 relatively strict implementation of the standard, which is commonly referred to as more environmentally friendly, but the so-called business e0 level is sometimes just a rhetoric, the best time to buy Look at the relevant files. Can not let its flicker.

- Q:Calcium silicate board is what material

- Calcium silicate board as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, the more excellent performance of calcium silicate board and moisture resistance, the advantages of long life, a large number of industrial and commercial applications in the ceiling ceiling and partitions, Home decoration, furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall. It is a high-quality high-grade cement as the base material, and with natural fiber reinforced, the advanced production process molding, pressure, high temperature steaming and other special technology and made, is a good performance of the new building and industrial Plate of its products fire, moisture, noise, insect moth, durable. Is the ceiling, cut off the ideal decorative plate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Magnesium Oxide Fireproof Board (mgo board) Europe Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords