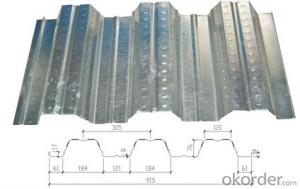

Galvanized corrugated sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

corrugated steel sheet1.shape:wave shape

2.wave number:9-12

3.weight per package:about 3 tons

4.certificate:BV ISO SGS

Roofing steel sheet

Thickness | 0.123-0.8mm |

Width | 665-1100mm |

Length | As request |

Zinc coating | 50-220g/m2 |

Pitch | 76mm or as request |

Wave height | 18mm or as request |

Wave No. | 7-12 |

Type | steel plate |

Weight of each package | about 3 mt |

Technology | cold rolled |

Material | SGCC SGCH DX51d |

Standard | ASTM,GB,JIS,DIN |

Price | FOB XingangUSD800-1200 per mt |

Packing | packed in iron sheet lined with kraft paper or as per client's request. |

Surface treatment | galvanized,corrugated,bright finished,chromated,oiled(or unoiled)

|

Delivery time | within 30 days after receiving the down payment or irrevocable L/C at sight

|

Payment | 30% down payment of the total value by T/T and the balance must be paid by T/T or irrevocable L/C at sight after the goods finished. |

Application | it is widely used in construction, factory warehouse,etc.

|

- Q:Millennium mill plate is good or the new millennium plate is good

- The new millennium ah ~ Millennium boat operator line brand, the brand with the price on the expensive ah But the new millennium count the second line of the brand, although the fame of thousands of years, but the quality is still very good drops, but also e0 level of eco-eco-board, compared to the price also offers! So for me this ordinary people still feel better than the new millennium!

- Q:What kind of sheet is more environmentally friendly?

- Norby forest plate are more environmentally friendly E1 level is the formaldehyde emission is 1:00, E0 level is 0:00, of course, E0 level more environmentally friendly

- Q:Now on the market E0 grade plate how? Now on the market E0 grade plate how?

- According to the European environmental standards, the wood products in accordance with the release of formaldehyde content, divided into three levels, namely E0 level (formaldehyde emission ≤ 0.5mg / L), E1 level (formaldehyde release 0.5mg / I ~ 1.5mg / L), E2 level (formaldehyde emission greater than 1.5mg / L). Only to obtain E1-certified wood products can be used for interior decoration, known as green building materials, absolutely no harm to the human body, E0-class plate is the highest environmental standards of wood-based panels, suitable for children, pregnant women and other resistance Low room decoration of the crowd. E0 grade sheet, refers to the international top environmental standards, formaldehyde emission ≤ 0.5mg / L medium density fiberboard, high density fiberboard, particleboard, oriented particleboard and other furniture can be used for furniture and home improvement wood products, E0, E1, E2 is the detection standard of formaldehyde emission.

- Q:What is the meaning of C in 13.5 * 1500 * C in plate specifications?

- In front of the thickness and width, C said length, according to need to determine.

- Q:Board grade divided into

- According to state regulations, the environmental protection level of wood is divided into three categories: E0, E1 and E2. Environmental protection level E0 level: E0 level is the current national standards and related to the detection of ecological sheet of the highest environmental standards. Because the 0.5mg / l formaldehyde content is already a very safe numerical standard. According to relevant information, the formaldehyde content of drinking water is 0.9mg / l, that is, E0 grade formaldehyde content is less than drinking water. Environmental level E1 level: in accordance with state regulations, the indoor plate environmental protection level must be achieved E1 level was considered standard, that is safe and environmentally friendly, the human body will not cause harm. In recognition of the quality of the plate at the same time, the most concerned about the furniture used by the formaldehyde emission of sheet metal. E1-level environmental standards are mandatory national health standards, is mandatory "safety standard line." E1 <= 1.5mg / l, that is, 1.5mg / l formaldehyde content is in line with national standards, is environmentally friendly, harmless to the human body. Environmental level E2: E2 <= 5mg / l, E2 level of formaldehyde content has exceeded the national standard, the current production industry in the plate industry is very few E2 grade, E2 grade products must be treated after finishing to be used Interior decoration.

- Q:What is the problem with the plate at the time of picking?

- To select the quality standards, such as Huaxiang plate, the products are manufactured after the relevant testing! Pay attention to the relevant grade and certificate of the sheet!

- Q:Are man-made sheets containing formaldehyde?

- Adhesive, with formaldehyde. No aldehyde glue seems not much. How much formaldehyde, and the quality and amount of glue. So buy the floor, pure wood the most environmentally friendly.

- Q:How much profit margins of decoration materials

- Tiles profit is relatively large, see what you take the route, the brand profit the largest, the smallest profit transfer, wood floor is the same

- Q:First, the backplane is generally 9MM, the door is generally 15MM, the cabinet is generally 18MM, the reasons are as follows, the cabinet is shaped, basically rarely move it, 9 thick wall, without any strength, cost Reduce the door to do the paint, both sides of the panel also add up to 15 +3 * 2 = 21, do not say, the general plate can not do paint, must be decorated panels, and drawers with nine thick floor , Taking into account the drawer space and weight problems, the use of convenience, as well as the aesthetic degree, so that, so that the cost is reduced, without affecting the use, and beautiful, if it is a board furniture finished cabinet, may use 18MM , Taking into account its stability

- Plate furniture is not really good if the back of the wardrobe with a thin backplane is even more ideal you will feel the cabinet will shake the drawer floor is too thin will collapse

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized corrugated sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords