Wood Plastic Composite Wpc Decking Floor/garden Composite Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Packaging & Delivery

| Packaging Detail: | Packed with pallet. |

| Delivery Detail: | Within 2 weeks got the deposit. |

Specifications

wpc decking

1.Place of Origin: CN; ZHE;

2.Features: Waterproof,Fireproof;

3.Application:park,garden.

4.Certificate: ISO 9001

Product Description

2014 New Outdoor 146x24mm WPC Decking Prices For Public

Wood plastic composite(WPC)made of 50% wood fiber and 50% PP,PE or PVC resin together with specialized ingredients, imported pigment, and anti-UV material. WPC products possess the advantages of good intensity, high rigidity, durable usage period, moisture proof, anti-abrasion, heat insulation, fire-resistant, aging-resistant, cauterization-resistant, water proof, insect resistant, and no painting needed. WPC products can be widely used in public garden or park, construction decoration, villa garden and so on.

Features:

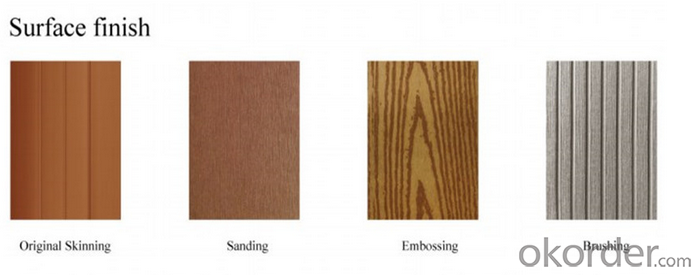

1. Natural wood texture

2. 15-20 years long life time, anti-impact, weather- proof, with high density

3. Anti-UV, color stability

4. small water swelling: only 0.05% (Europe request standard ≤0.1%)

5. Easy to be installed and low labor cost

6. Required no painting, no glue, low maintenance

7. 100% recycled, environmental friendly, saving forest resources

8. Barefoot friendly, anti-slip, no cracking

9. Weather resistant, suitable from -40°C to 65°C

Technical Index:

| Techinical Index | |||

| No. | Property | Result | Text Method |

| 1 | Density | 1.23g/cm | ASTMD792 |

| 2 | Water absorption | 0.50% | ASTMD570-00 |

| 3 | Tensile strength | 14.2Mpa | ASTMD638-03 |

| 4 | Elongation Rate at break | 3.90% | ASTMD638-03 |

| 5 | Flexural strength | 30.0Mpa | ASTMD790-03 |

| 6 | Flexural modulous | 3500Mpa | ASTMD790-03 |

| 7 | Linear expansibility | 4.9×10—5°C-1 | ASTMD696-03 |

| 8 | Compress strength | 26.4 | ASTM695-02 |

| 9 | Impact streght(unnotched)-25°C—+30°C | 90.1 J/m | ASTMD256-03 |

FAQ:

(1) what is WPC ?

SGB WPC is a green buidling material, it's made of 60%-65% natural wood fiber( Professionally Dry treatment ) ,30%-35% of eco-friendly HDPE materials and 5% -10% Chemical additivel ( anti-UV agent, anti-oxidation agent, reinforcing agent, stabilizers, colorrants, anti-fungus agent, coupling agent ect..).

(2) How long is the service life of WPC product ?

15-20yeras.

(3) What the weather temperature is suitable to use our WPC products ?

It's from -40°c to 60°c.

(4) Do WPC product need the good ventilation and drainage ?

Yes, like timber, it's important to provide adequate ventilation and drainage to ensure SGB WPC is able to dry out after being wet. For this reason, it's very important to pay attention to clearance on butt joins ( end to end), spacing between boards( side to side), and min. ground clearance. Lack of ventilation and drainage can cause the products to swell over time. Check product fix informations on the good ventilation and drainage requirements. Boxing in the deck will reduce cross flow ventilation and therefore should be avoided.

- Q:Composite floor was blisters, how to do?

- If the soaking time is not long or the floor deformation is not very serious, you can take the following methods: the four lines around the T-line first removed, if the floor is not a long time, So that the floor under the water vapor distribution, after a long period of time after the floor can be restored. A better way to be able to remove the Alice all the floor (of course, the installation is not or only a small amount of sizing), and so completely dry and then loaded back, this will restore some of the better performance of the pilgrims pilgrimage. Good floor will be restored a little more, but it is difficult to restore to the status quo!

- Q:How to deal with composite floor cracks

- 1. buy "bakelite powder" with a dish Sheng, drip into the water to the slurry, and then brush the cracks, a little spray into the water, fill in the bakelite pulp can be. Usually a night time bakelite pulp will dry through the hard, the floor can be trampled as usual. 2. You can use wood chips (sawdust) and alum, toner and water into a paste, fill in the cracks in the cracks, to be dry after the sandpaper with water sanding smooth, and then brush on the varnish can be. 3. The quality of the floor, you can find a dealer asked to rework or compensation in the love of living above a lot of composite floor cracking solution, there is time you can learn from. I wish you an early solution!

- Q:What is the padded floor under the composite floor?

- What is the padded floor under the composite floor?

- Q:It is good or seamless for the elephant floor

- There are two kinds of composite floor chamfering plate and molding plate. There are cracks for the chamfering board, seamless for the molded plate: carefully observe the chamfering board around the paint for the edge, there is no wear-resistant layer, and can not be a strict fit, the middle of a gap will seepage into the seepage, Good care. At the same time the paint side will be 1-2 years off, the substrate exposed to the outside, the water will penetrate into the substrate greatly affect the life of the floor. And the pressure plate wear layer is extended to the edge of the surface is a whole; combined with the assembly after the tight seam, just to make up for the lack of chamfer board. Another key can not be ignored is the lock, chamfering board is often flat buckle, in the process of flat buckle easy to fall off; and the new arc intelligent deduction bite force to avoid the use of the process of the above problems. Choose the floor to choose the floor as long as the sharp eyes, identify the substrate · wear-resistant technology do not have to spend the blood of this still can buy a satisfactory floor.

- Q:Hello,We had an engineered oak floor installed in our home two weeks ago. The floor was glued down over the cement slab. What we have noticed is (1) there are a lot of gaps between the slats (some as big as 1.5 mm); and (2) there is one area where the glue did not stick and now the wood is lifting. This area is in the middle of the entry hallway and we hear a hollow sound when walking on this place (it can be pushed down by hand). My question is are these normal or do we need to contact the installer/dealer to have something done or complain? Thanks in advance for your advice.Jim

- I'd start by getting the installer back in to see your problem. It may be an easy fix.

- Q:The use of composite flooring for a long time, a little dirty, dark, in the supermarket in the sea over the fall of the name of the law, but the feeling of no effect, there is no other better way to clean the complex cleaning floor. The composite floor color itself is a little light, so a dirty, to see the special clear. Thank you heroes Weapon. More

- Decoration

- Q:Solid wood flooring installation need to pay attention to it

- Do not understand, to complete the task only

- Q:Is about to pay the election of the election of wood flooring, read a lot, do not know which floor good point, also please Supreme guidance! Question added: a good floor can also recommend Ha! Price slightly cheaper! Composite floor! More

- One of the top ten brands of laminate flooring: one of the top ten brands of flooring composite flooring: one of the top ten brands of composite wood flooring: one of the top ten brands of composite wood flooring: One of the top ten brands of flooring: Cicero flooring composite wood flooring one of the top ten brands: Parker floor composite wood flooring one of the top ten brands: Kenya floor composite wood flooring one of the top ten brands: Yangtze flooring composite wood flooring One of the top ten brands: macro resistance to harm the official car to mention the rules of the sea plate off the board of one of the top ten brands: Kyrgyzstan as the floor of the floor is like a solid wood do not know the complex you can go to see Thank you for the above composite floor

- Q:Recently to decorate the house, want to put the bedroom covered with composite flooring, but do not know the shop composite floor and floor tiles that is good, please give me some instructions, and if the election of the floor to choose a single card into the toilet, What kind of good, the price probably in a lot? More

- Recently to decorate the house, want to put the bedroom covered with composite flooring, but do not know the shop composite floor and floor tiles that is good, please give me some instructions, and if the election of the floor to choose a single card into the toilet, What kind of good, the price probably in a lot? More

- Q:Home decoration to shop composite floor, in the decoration of the city to see a very bright surface of the composite floor, the effect and the wax on the same as the solid wood flooring, and even bright. Called mirror floor. Do not know this floor can not buy, what exactly what the surface painted, so bright. How about the wear resistance, will not be a long time there is irreparable wear marks. Who is the home of the power ridge ding boge hi gong but the fence of this floor, please come to a proposal. Thank you More

- The earliest piano flooring behind the high hardness, but the floor is the floor about a year or so scratch is normal

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Plastic Composite Wpc Decking Floor/garden Composite Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords