Vapor Barrier Membrane with Reflective Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vapor Barrier Membrane with PE Film and Non-Woven Fabric

Company Information:

We are located in National Development Zone in Nantong, with 22000 square meters area, including 7000 square meters dust free workshop.

We have equipped the most advanced pp non-woven production line and composite production lines including extrusion lamination production, hot melt lamination production line, calendar bonded production line with the technology from Italy and Germany, printing production line, cutting production line. We specialize in producing waterproof and breathable materials and heat insulation materials, pp non-woven fabric, disposable medical products, packaging materials and so on.

Products Information:

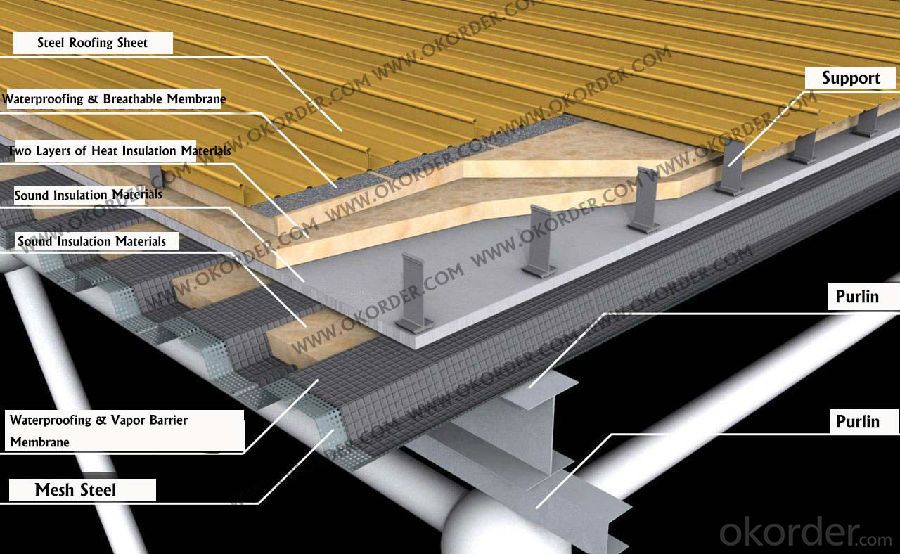

Vapor Barrier membrane is a roof membrane with three-layers, which is specially designed for application on ventilated pitched roofing, can be used under bituminous membrane as a extra protection for the attic insulation. It includes PET/PP non-woven fabric layer, PE/PP woven layer and aluminum foil layer. The three-layers structure ensure extreme resistance to tearing. Furthermore, the special stabilization additives ensure 3-month resistance to UV radiation.

Specifications:

Chemical Composition | PP & PE, Aluminum Foil, Woven Fabric |

Roll Size | 1.5meter*50meter |

Density: | 60gsm~130gsm |

Tensile Strength | MD:150N/50mm; CMD:115N/50mm |

Waterproofing Rate | W1 |

Vapor Resistant Rate | 6.9g/m2 ▪ 24h |

Aging rate under hot circumstance (90℃*168h) | MD:90%; CMD:100% |

Typical Application:

Container Loading:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q:Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Need to waterproof the external walls, there are several programs. First, directly in the existing external walls of the main surface of the water treatment, the use of technology and materials due to different external finishes and different;

- Q:Slope roof drains do not need to be waterproof

- In addition, according to conventional settings vertical and horizontal sub-grid, complex structure easy to leak.

- Q:Eastern rainbow waterproof how to do

- especially small places to pay attention, such as: sewer such as. And then dry about 10 hours or more, (see the environment may be, like a dry) so repeated 3 side painting is appropriate.

- Q:Find the construction steps for waterproof coatings

- 3, note (1) rain weather and five wind above the weather shall not be construction. (2) coating waterproof layer shall not have bottom leakage, cracking, holes and other defects and peeling, bubbling, carcassing and wrinkle phenomenon. Coating waterproof layer and the base should be bonded between the solid, no hollowing, trachoma, delamination and so on. (3) the coating site should be continuous, solid, shall not appear Alice, hollowing parts. (4) rigid protective layer before the completion of any personnel shall not enter the construction site, so as not to damage the waterproof layer; coating of the overlapping parts should be care by the staff. (5) roof should be used lime soil, clay or sub-clay for backfill, thickness 50 cm, backfill shall not contain stones, gravel, ash and organic matter. Artificial compaction of each layer 25 cm, mechanical compaction of each layer 30 cm, rammed to prevent damage to the waterproof layer. In the backfill thickness of more than 50 cm, it is allowed to use mechanical backfill rolling.

- Q:What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 2: aluminum plate material ????Aluminum buckle board is based on aluminum alloy as the main substrate, through the process to get the finished product, and now the aluminum plate in the use of integrated ceiling in the larger. In the home improvement specifications are generally 300MM * 300MM, 300 * 450mm, 300 * 600mm and other different sizes, because of its excellent board layer, with noise, heat insulation, light weight characteristics, while its color is also more Kind of choice, to meet the different needs of consumers.

- Q:Roof sunscreen waterproof layer leakage, brush milk white plastic can solve it?

- three, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt watering, and now have finished asphalt coating, and so on when the sunny day to deal with the basic It will not leak. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

- Q:I would like to ask how to do in the warm water above,

- Do nothing to use, because the biggest leak to the hidden danger is to warm the water, but your waterproof design does not include the warm water, you say your waterproof layer construction, in the end how much significance. It is recommended to make the waterproof floor to warm the following, as to what kind of good is not good to say that good things, that kind of good is good.

- Q:Home improvement waterproofing problem

- 4, through the door stone paving need to do waterproof, you can directly use cf-2000 efficient composite waterproofing agent treatment, can play paste, waterproof two effects. Just on both sides of the door to do the character to strengthen the treatment on the line can be foolproof.

- Q:How does the waterproofing membrane work?

- 3, the ignition: first open the liquefied gas cylinder switch, and then hand gun slowly open the gun switch, to be heard when the gas hissing sound, ignite the flame, and then adjust the switch, the flame was blue. Ignite people should stand behind the nozzle side, so as not to be burned by fire;

- Q:What material waterproofing can be mixed with cement sand

- Construction can also be used to produce waterproof pulp, waterproofing agent for the amount of cement 3 ‰ -4 ‰, the use of cement label not less than 32.5MPa.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vapor Barrier Membrane with Reflective Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords