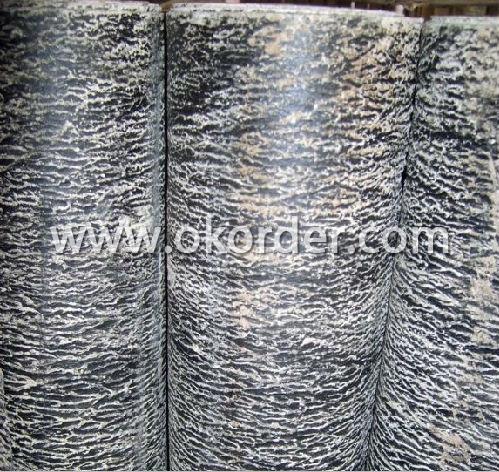

High Quality Asphalt Roofing Felt

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 Square Meter m²

- Supply Capability:

- 300000 Square Meter per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Asphalt roofing felt is conformity with ASTM standards of the USA.

The roofing felt is widely used as underlayment which is under asphalt shingles. Its saturation rate is 100%,that’s to say, both water and air cannot enter.

Detailed Specification of Asphalt roofing felt:

Item | Width | Length | Weight | Thickness | Usage |

ASTM D-226 roofing felt 30# | 36in 0.914m | 72ft 21.95 m | 23.5kg | 1.2mm | A roofing felt used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings. |

ASTM D-226 roofing felt 15# | 36in 0.914 m | 144ft 43.89 m | 23kg | 0.8mm | |

ASTM D-4869 roofing felt 15# | 36in 0.914m | 144ft 43.89m | 16.5kg | 0.6mm | |

ASTM D-4869 roofing felt 30# | 36in 0.914m | 72ft 21.95m | 13.5kg | 0.8mm |

Usage of Asphalt Roofing Felt:

A roofing felt used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings.

- Q:Bathroom first leveling or do waterproof, what is the difference

- Is the first water and then leveling. Home improvement toilet ground specific process practice: 1. The base layer, and which layer with the structural board, with cement mortar wipe. It is recommended to set the floor drain, the grassroots level should be flat and the direction of the leak to the slope. Against the wall and the root of the root should be wiped rounded.

- Q:Cabinet is to buy finished products, or directly to the decoration company to do?

- Do the cabinet can be in accordance with your size, finished cabinet moldy, which is not necessarily. You have to buy some of the Well

- Q:There is no formaldehyde in the finished putty

- Visible putty powder and formaldehyde or a great relationship, but now many manufacturers have introduced environmentally friendly putty powder, not only environmentally friendly pollution-free important is also can control the air, there is a negative ion putty powder is the composition which contains tourmaline tourmaline, through And the water molecules in the air combined with the decomposition of negative ions to deal with the air, anion can be neutralized with formaldehyde into dust falling into the air, you can also remove the dust in the air, as well as enhance the metabolism of the function.

- Q:Roof sunscreen waterproof layer leakage, brush milk white plastic can solve it?

- three, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt watering, and now have finished asphalt coating, and so on when the sunny day to deal with the basic It will not leak. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

- Q:I would like to ask how to do in the warm water above,

- Rough housing or liquid with a good, airtight than the coil is good, all-pervasive, if there is a trachoma in the case of white do not see the white. If the building from the building if the first waterproof, finished product protection is a problem.

- Q:Hello, roof with SBS waterproof material bulk density is how much?

- SBS Styrene-based thermoplastic elastomer is the largest yield (more than 70%) of SBCs, the lowest cost and wider application. It is a triblock copolymer with styrene and butadiene as monomer. Plastic and rubber properties, known as the "third generation of synthetic rubber".

- Q:What is the price of a waterproof window cover?

- 3, decorative panels Decorative panels are divided into paint-free panels and paint panels. Currently on the market, there are many window-free products, paint-free board is 5 mm density, the board pressure a layer of thin layer of color paper, due to the type of color paper, so there can be a lot of paint-free Color. Paint decorative panel is the surface of a layer of veneer plywood, there are many types, different wood has different colors. The benefits of window sets

- Q:Can acrylic materials be perforated? How to do waterproof after punching?

- It is best not to drill in the finished product on the screen, if it is absolutely last resort, You can use fiberglass material in the hole position paper;

- Q:FRP finished brush on what can be waterproof do not fade

- With glass fiber reinforced plastic + color paste even after the use of. Can be waterproof.

- Q:How to do waterproof bathroom, construction process is what

- 4, closed water test. Closed water test, the highest point of the ground water can not be less than 2 cm, save at least 24 hours, observe the phenomenon of no leakage after the operator. If there is leakage, need to redo, and can not neglect.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | America; Europe; Asia; the middle east |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 50% - 100% |

| No.of Employees in Trade Department | 6 - 10 people |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 20000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

High Quality Asphalt Roofing Felt

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 Square Meter m²

- Supply Capability:

- 300000 Square Meter per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords