Tri Dimensional Composite Drainage Geonet For Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 M2 m²

- Supply Capability:

- 280000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

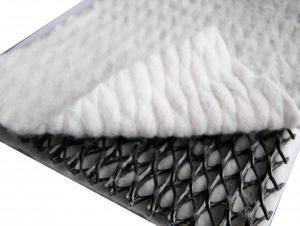

Introduction of Tri Dimensional Composite Drainage Geonet:

Tri-dimensional composite drainage geonet is made of a unique tri drimension geonet adhibit geotextile on both sides. It has the property of geotextile(filtration function) and geonet (drainage and protection) and provide a function system “filtration—drainage—protection”. The core of net with its unique tri-dimension structure can bear higher compressing load in construction and remain the certain thickness, provide good water conductivity.

Application of Tri Dimensional Composite Drainage Geonet:

Landfill drainage; roadbed and road drainage; railway drainage ,tunnel drainage, underground structure drainage, the retaining back wall drainage, gardens and sports grounds drainage.

specifications and technical parameters of Tri dimensional composite drainage geonet:

Drainage network core | Units | Specifications | |||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 |

Thickness OV=20kpa | mm | 5.0 | 6.0 | 7.0 | 7.6 |

Hydraulic conductivity | m/s | K×10ˉ4 | K×10ˉ4 | K×10ˉ4 | K×10ˉ4 |

Elongation | % | <50 | <50 | <50 | <50 |

Tensile strength (core network) | KN/m | 8 | 10 | 12 | 14 |

Geotextiles | g/m2 | 200-200 | 200-200 | 200-200 | 200-200 |

The contrast of Tri dimensional composite drainage geonet and natural grit drainage layer

Application | Tri-dimension composite geonet for drainage | Natural Gravel |

Conducting and discharging Water and gas | Pass through strict quality control production line and have stable performance and good property of conducting water | The traditional gravel have complex composition and its drainage property change with its attribute. Its actual drainage property is much lower laboratory data for its contains of sand and dust. |

Load/Protection | Light, no more extral load on geomembrane and waste. Anti-pull, anti-compress, anti-impact and can prevent geomembrane from damage | Pressure on the waste, the keen stone can puncture and damage geomembrane. Often need other safeguard, such as thicker geotextile. |

Function | Four functions: drainage, separation, filtration and protection | Only drainage function, easy be blocked, and need accessorial filtration system. |

Construction and installation | Fast installation, easy for construction, without heavy machinery and professionals. Construction speed is 5-10 times of gravel. | Slow installation, bulky and heavy, need heavy machinery. High cost and have more difficulties with slope degree is more than 1V:4H. |

Environment | Raw material is polyethylene, nontoxic, no pollution, 100% recyclable products. | Relatively speaking, the gravel is scarce and precious resources. The ecological environment will be destroied when people mine gravel. |

Durability | Good anti-erosion, antioxidation, anti-atmospheric media and rain water. It have long-term and the best drainage property if used them along with the geotextile. | Be easily blocked, has poor durability. |

- Q:Can earthwork products be used for canal construction?

- Yes, earthwork products can indeed be used for canal construction. Earthwork products, such as clay, soil, and aggregate materials, are commonly used in canal construction for various purposes. These materials can be used for excavation and leveling the canal bed, constructing embankments, lining the canal walls, and providing stability and erosion control. Additionally, earthwork products can also be used for backfilling and landscaping around the canal area. Overall, earthwork products play a crucial role in canal construction projects.

- Q:Are earthwork products resistant to weathering?

- Yes, earthwork products are generally resistant to weathering. Due to their composition and natural characteristics, earthwork products such as soil, clay, and rock tend to withstand weathering processes such as erosion, moisture, and temperature changes. However, the extent of their resistance can vary depending on the specific type of earthwork product and the intensity and duration of weathering conditions.

- Q:How are geosynthetic materials used in coastal protection structures?

- Geosynthetic materials are commonly used in coastal protection structures to enhance their stability and durability. These materials, such as geotextiles, geogrids, and geomembranes, are employed for erosion control, slope stabilization, and wave attenuation. They act as a barrier against soil erosion, prevent the loss of sediment, and provide reinforcement to the structure. Geosynthetics also help in reducing wave impact on the coastline, thereby protecting it from erosion and damage.

- Q:What are the different surface finishes available in earthwork products?

- Some different surface finishes available in earthwork products include smooth finishes, textured finishes, exposed aggregate finishes, stamped finishes, and colored finishes.

- Q:How do earthwork products affect the overall structural stability of a project?

- Earthwork products, such as soil, gravel, and rocks, play a crucial role in determining the overall structural stability of a project. These materials are used as foundations, backfills, and retaining structures, providing support and stability to the structures built on top of them. The quality, properties, and compaction of earthwork products directly influence the load-bearing capacity, settlement, and resistance to external forces of a project. Proper selection and compaction of these materials are essential to ensure the long-term stability and safety of the project.

- Q:What are the benefits of using geosynthetic clay liners in mining applications?

- Geosynthetic clay liners (GCLs) offer several benefits in mining applications. Firstly, they provide an effective barrier against seepage and leakage of potentially harmful fluids, such as acid mine drainage, preventing contamination of groundwater and surrounding ecosystems. Additionally, GCLs have excellent hydraulic conductivity properties, allowing for efficient drainage and reducing the risk of slope instability. Their high tensile strength and puncture resistance make them durable and reliable, withstanding the harsh conditions often found in mining environments. GCLs also offer cost savings compared to traditional clay liners, as they require less excavation and compaction, resulting in reduced construction time and expenses. Overall, the use of GCLs in mining applications enhances environmental protection, improves safety, and offers economic advantages.

- Q:What is the purpose of using geocomposites in subsurface drainage systems?

- The purpose of using geocomposites in subsurface drainage systems is to enhance the efficiency and longevity of the drainage system. Geocomposites are engineered materials that combine geotextiles with other components like drainage cores or geonets. These materials help to improve filtration, water flow, and soil stabilization in drainage systems. They provide a barrier against soil clogging, prevent the intrusion of fines, and facilitate the collection and removal of excess water from the subsurface. Ultimately, geocomposites help to prevent waterlogging, soil erosion, and maintain the overall stability and functionality of the subsurface drainage system.

- Q:How can geopipes be used in underground utility tunnel projects?

- Geopipes can be used in underground utility tunnel projects to efficiently manage and transport various utilities such as water, gas, and telecommunications. These pipes are durable, resistant to corrosion, and can withstand heavy loads, ensuring safe and reliable infrastructure. Additionally, the use of geopipes minimizes the need for frequent maintenance and repairs, reducing project costs and increasing overall efficiency.

- Q:The relationship between material development and civil engineering development

- The emergence and development of new materials to promote the human society and history, civilization, progress. Material is the material basis of human production and life, is the direct driving force of social development. The development of materials and its application is an important milestone in human civilization and social progress

- Q:Can geosynthetics be used for reinforcement in road construction?

- Yes, geosynthetics can be used for reinforcement in road construction. Geosynthetics, such as geotextiles and geogrids, are commonly used to enhance the stability, strength, and longevity of roads. They help distribute loads, reduce the risk of cracking and rutting, and improve overall pavement performance.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port,China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese; Russian; Spanish |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Tri Dimensional Composite Drainage Geonet For Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 M2 m²

- Supply Capability:

- 280000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches