Three Layers Geotextile Composite Geomembrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geotextile Composite Geomembrane Description:

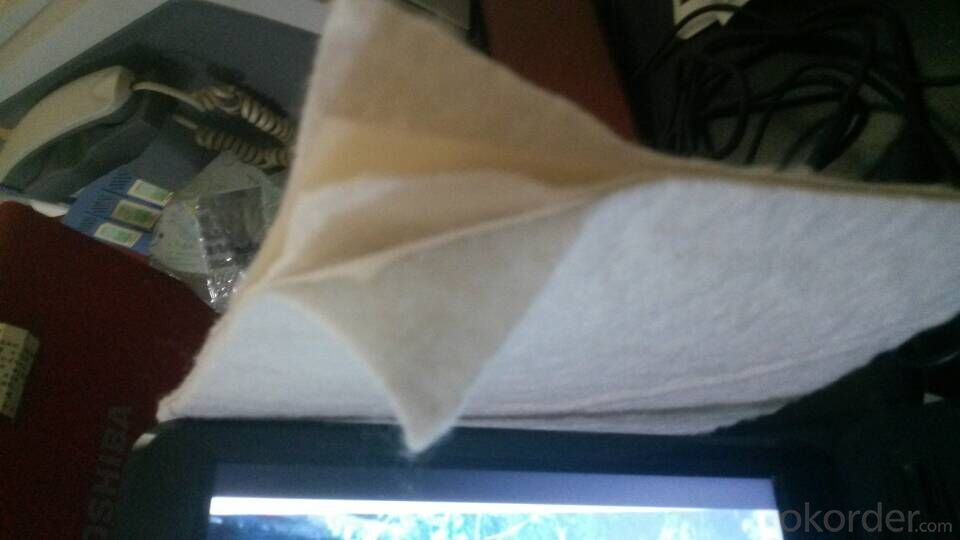

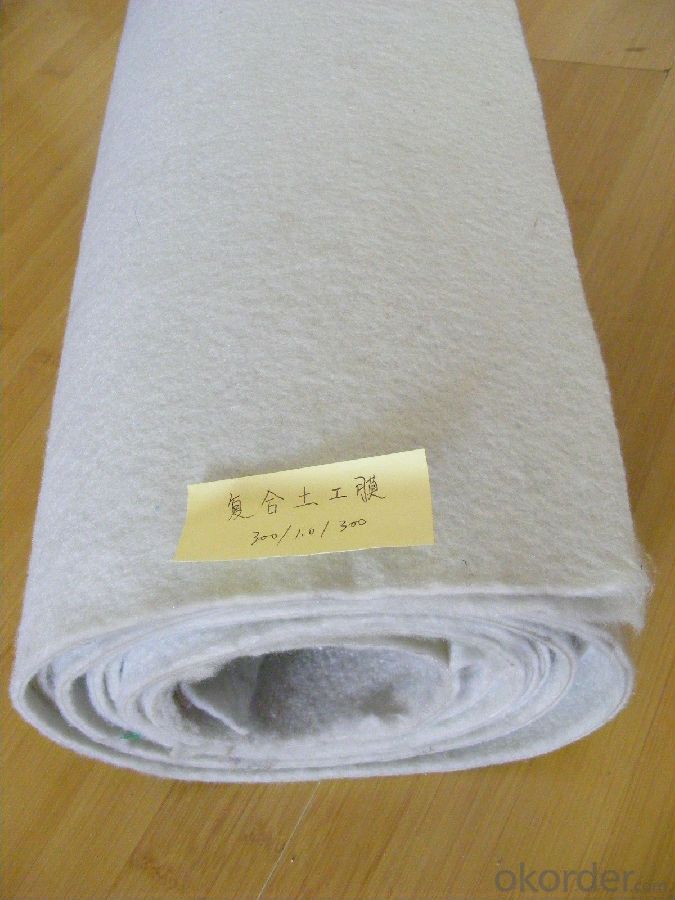

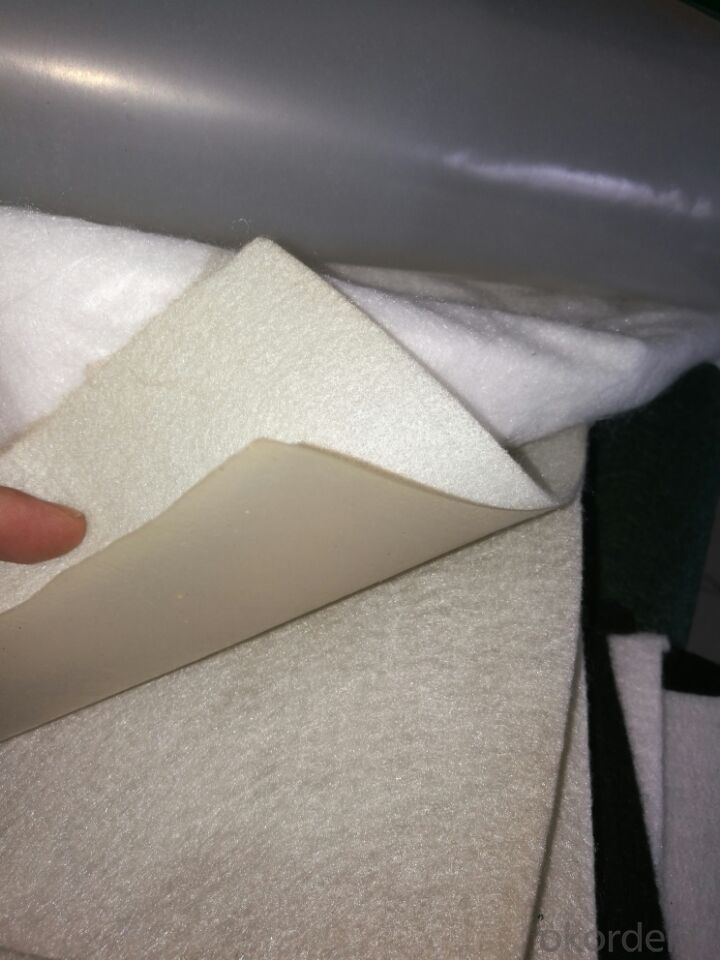

Geotextile composite geomembrane is made by nonwoven geotextile and PE/PVC geomembrane. It has geotextile and geomembrane, geomembrane with nonwoven geotextile on both sides, nonwoven geotextile with geomembrane on both sides, multi-layer geotextile and geomembrane.

Geotextile Composite Geomembrane Specification:

1)One geotextile and one geomembrane: geotextile 100-800g/m2, geomembrane 0.1-1.0mm

2)Geomembrane with geotextile on both sides: geotextile 100-400g/m2, geomembrane 0.2-1.0mm

3)Geotextile with geomembrane on both sides: geotextile 100-800g/m2, geomembrane 0.1-0.8mm

Geotextile Composite Geomembrane Technical Data Sheet:

Table 1: one layer geotextile + one layer geomembrane

Item | Unit | Specification | |||||||

Weight unit area | g/m2 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | |

Structure | Geotextile | g/m2 | 150 | 200 | 300 | 300 | 300 | 400 | 400 |

Geomembrane | mm | ||||||||

Tensile strength at break | kn/m | 6 | 11 | 14 | 16 | 18 | 20 | ||

Elongation at break | % | 30-100 | |||||||

Tear resistance | Kn | ||||||||

CBR | kn | 3 | |||||||

Vertical permeability coefficient | Cm/s | 1*10-12

| |||||||

Hydrostatic pressure resistance | Mpa | ||||||||

Table 2: two layer geotextiles + one layer geomembrane

Item | Unit | Specification | |||||||

Weight unit area | g/m2 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | |

Structure | Geotextile | g/m2 | 100 | 100 | 150 | 200 | 200 | 200 | 200 |

Geomembrane | mm | ||||||||

Tensile strength at break | kn/m | 6 | 11 | 14 | 16 | 18 | 20 | ||

Elongation at break | % | 30-100 | |||||||

Tear resistance | Kn | ||||||||

CBR | kn | 3 | |||||||

Vertical permeability coefficient | Cm/s | 1*10-12

| |||||||

Hydrostatic pressure resistance | Mpa | ||||||||

Geotextile Composite Geomembrane Property:

Good flexibility; separation, reinforcement and protection; waterproofing

Geotextile Composite Geomembrane Application:

Reinforcement in channel; embankment, reservoir; waterproofing in reservoir; rock fill dam and transportation tunnel.

- Q:Can earthwork products be used for creating outdoor seating areas?

- Yes, earthwork products such as gravel, sand, and soil can be used to create outdoor seating areas. These materials can be used to construct a solid foundation for seating structures like benches, retaining walls, or even raised platforms. Additionally, earthwork products can be used to level the ground or create slopes to enhance the comfort and aesthetics of the seating area.

- Q:How can geocomposites be used in subsurface irrigation systems?

- Geocomposites can be used in subsurface irrigation systems by acting as a barrier to control water flow, preventing soil erosion and enhancing water distribution to plant roots. They help to evenly distribute water throughout the irrigation area, reducing water waste and increasing efficiency. Additionally, geocomposites can improve the overall performance and longevity of the irrigation system by providing stability and protection against clogging and root intrusion.

- Q:Do earthwork products require any special installation techniques?

- Yes, earthwork products often require special installation techniques due to their weight, size, and composition. These techniques may include proper site preparation, grading, compaction, and drainage considerations to ensure the stability and longevity of the installation. Additionally, some earthwork products, such as geotextiles or geogrids, may require specific methods for anchoring or joining them together. It is important to follow manufacturer guidelines and consult with professionals experienced in earthwork installations to ensure proper techniques are employed for optimal results.

- Q:What are the advantages of using geosynthetic liners in secondary containment systems?

- Geosynthetic liners offer several advantages in secondary containment systems. Firstly, they provide a reliable barrier against leaks and spills, preventing hazardous substances from contaminating the environment. Additionally, they are highly durable and resistant to corrosion, ensuring long-term containment integrity. Geosynthetic liners are also flexible and easy to install, allowing for customization to fit various shapes and sizes of containment areas. Moreover, they are cost-effective compared to traditional options such as concrete, reducing construction and maintenance expenses. Overall, geosynthetic liners enhance the safety and effectiveness of secondary containment systems.

- Q:What is the purpose of using geocomposites in subsurface drainage systems?

- The purpose of using geocomposites in subsurface drainage systems is to enhance the performance and efficiency of the drainage system. Geocomposites, which consist of a combination of geotextiles and geonets or geospacers, provide a range of benefits such as filtration, separation, and reinforcement. These materials help to prevent clogging of the drainage system by filtering out fine particles, while also facilitating the flow of water through the system. Additionally, geocomposites can improve the overall stability and longevity of the drainage system by providing reinforcement and preventing the migration of soil particles. Overall, the use of geocomposites in subsurface drainage systems helps to ensure effective water management and prevent issues such as soil erosion and waterlogging.

- Q:How do geosynthetic products contribute to soil erosion prevention in vineyards?

- Geosynthetic products help in soil erosion prevention in vineyards by providing reinforcement and stabilization to the soil. These products, such as geotextiles and geogrids, are used to create a protective layer that helps retain soil particles in place, minimizing the risk of erosion caused by water runoff or wind. Additionally, geosynthetics can improve soil permeability, enabling better water infiltration and reducing surface runoff. By reducing erosion, geosynthetic products support the growth of healthy vineyards, maintaining soil fertility and preventing the loss of valuable topsoil.

- Q:What are the different types of geotextile fabric installation methods?

- There are several different types of geotextile fabric installation methods, including direct placement, trench installation, and anchor trench installation. In direct placement, the fabric is simply laid directly on the ground or subgrade. Trench installation involves placing the fabric in a dug trench and backfilling it with soil. Anchor trench installation is similar, but includes the use of additional anchor trenches to secure the fabric in place. These methods are chosen based on the specific needs and requirements of the project.

- Q:What are the benefits of using geotextile fabrics in earthwork projects?

- Geotextile fabrics offer numerous benefits in earthwork projects. Firstly, they act as a barrier to prevent soil erosion by stabilizing the soil and preventing it from being washed away by water. Additionally, they enhance soil drainage and filtration, allowing water to pass through while retaining the soil particles. This helps in preventing waterlogging and maintaining the integrity of the soil. Geotextile fabrics also provide reinforcement to the soil, increasing its load-bearing capacity and improving the overall stability of the project. Moreover, these fabrics are durable, resistant to chemicals and UV rays, and have a longer lifespan, making them a cost-effective solution. Overall, the use of geotextile fabrics in earthwork projects reduces maintenance costs, extends the lifespan of the project, and promotes sustainability.

- Q:How do earthwork products contribute to wastewater treatment systems?

- Earthwork products, such as clay, sand, and gravel, play a crucial role in wastewater treatment systems. These materials are used in various components of the system, including the construction of settling tanks and filtration beds. Clay helps to line the walls of settling tanks, preventing the leakage of wastewater into the surrounding soil. Sand and gravel are used in filtration beds to remove impurities from the wastewater as it passes through. Overall, earthwork products provide the necessary infrastructure for effective wastewater treatment, ensuring the removal of pollutants and the protection of our environment.

- Q:How do geotextile tubes help in coastal erosion control?

- Geotextile tubes help in coastal erosion control by acting as a barrier against wave and current energy, preventing the erosion of coastal land. These tubes are filled with sand or other sediments and then positioned along the shoreline, creating a buffer zone that absorbs the impact of waves and reduces the erosion caused by water movement. Additionally, the geotextile material allows water to pass through while retaining the sediment, providing stability to the shoreline and promoting the formation of new dunes or beaches.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Three Layers Geotextile Composite Geomembrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords