Stud of Zinc Galvanized Stud of Zinc Galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

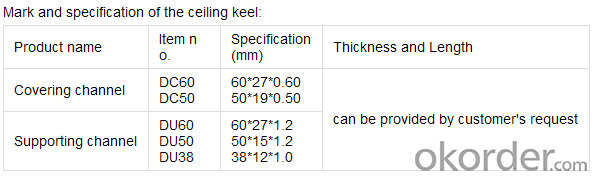

Product Specifications:

Images:

- Q:Why the ceiling keel

- 1, modeling should use the ceiling keel, only to facilitate the fixed gypsum board, carved panels, panels and other materials 2, can be directly used wood board primer, which is only suitable for small area ceiling keel, it acts as a keel role. Expansion: home use generally use wooden keel, tooling or large-scale ceiling is required to use light steel keel.

- Q:Master ceiling should choose what specifications of light steel keel

- The main bone C60 is shown on the chart

- Q:Home ceiling with green steel skeleton or wooden frame

- Wood keel and light steel keel is the installation of the ceiling when the material, plastic gusset installation need wood keel, aluminum ceiling installation can choose light steel keel and wood keel, but now the market are basically using light steel keel, after all, light steel Keel is metal!

- Q:What kind of size of the ceiling?

- 30 * 40

- Q:Light steel keel ceiling good or wood keel good? Residential. I want to use light steel keel, but the designer said the reasons for modeling, light steel

- Yes, the more complex shape of light steel can not do, such as s type. K type, heart type and other different types do not come out, the other can do. If you can not do, he may not work

- Q:Seeking: light steel keel mineral wool board ceiling, the general how much money a square? (The installation is complete)

- First to correct your mistake on the argument, the installation of mineral wool board dragon skeleton is called paint keel, rather than light steel keel. Second, the current market in Chongqing market point of view, Long card and Star USG mineral wool board is better, plus paint keel matching system and auxiliary materials (screw, expansion sets, T-type hanging pieces) and labor costs, loss , Management fees, etc., estimated at 48 yuan / square or so. For more information, please contact: Chongqing letter Lan Lan Fort Building Materials Co., Ltd.

- Q:Light steel keel ceiling calculation method

- Per square meter ceiling need: The main keel 1 meter, deputy keel 2 meters, stays up the keel 2 meters, while the keel for the ceiling around the total length (with the room size, shape). If you want to calculate in detail, it is necessary to see how the layout of the keel on the drawings. for example: The main keel spacing of 1.2 meters, along the length of the layout of the room; vice keel spacing 0.6 m; stays keel spacing 0.6 m; room length 6 m, width 4.5 m. The main keel is: 4.5 ÷ 1.2-1 = 2.75 (root), rounding requires three main keels, keel spacing adjusted to 4.5 ÷ (3 +1) = 1.125 meters. The main keel needs: 6 × 3 = 18 meters. Vice keel is: 6 ÷ 0.6-1 = 9 (root), keel spacing just to meet the design requirements of 0.6 meters. Vice keel need: 4.5 × 9 = 40.5 meters. Hold the keel is: 4.5 ÷ 0.6-1 = 6.5 (root), rounding requires 7 stays keel, keel spacing adjusted to 4.5 ÷ (7 +1) = 0.56 m. Hold the keel need to: 6 × 7 = 42 meters. Side keel need: (6 + 4.5) × 2 = 21 meters. In the material plan, each should also be added to the loss of 1 to 3% OK!

- Q:Wood keel and light steel keel were used for where?

- Wood keel is generally used in the living room and aisle ceiling, light steel keel used in the kitchen bathroom ceiling

- Q:Light steel keel ceiling ,,, Commonly used is 50 to 50 system ,,, Light steel keel, the surface after the heat crossing zinc treatment, and long no rust, no deformation ,,, State regulations installed on the light steel keel on the gypsum board, as a class A fireproof material Wood keel because the water is too large, and love deformation ,,, no fire, so you can see Large place, no one is covered with wooden keel. The There are two real problems: 1 "with wood keel, the effect is not bad, and the cost is not cheap ,,, now light steel 50 keel and 3 * 5 wooden cost

- Light steel keel has the following advantages: light steel keel long unchanged. Light steel keel, the surface of high galvanized, long no rust, more could not be pest ants. Light steel keel is non-combustible material, no fire hazard Light steel keel environmental protection beyond wood material; light steel keel installation no noise, connected firmly, and to ensure environmental health; light steel keel is a new ceiling material, widely used in home and engineering The Wooden wood ceiling damage: the absorption of air in the air, especially in the northeastern weather, thermal expansion and contraction, inevitable deformation, leading to gypsum board cracking and deformation; wood material easy insects, ants and other organisms, harmful to humans. Wood material strength is not enough, it is easy to produce gypsum board subsidence, deformation and other issues; code nail connection easy to loose, shedding wounding; woody materials flammable, easy to cause fire; wood material keel applications will use fire retardant coating, Material in the installation, there is a strong "formaldehyde" gas volatilization; wood keel in the installation, must use nail gun, the noise is great, and woods flying, stimulate the body skin; wood ceiling, partition is already eliminated A structure, the project has been not allowed to use. From the construction cost and cost of considering the difference between the two little, light steel keel construction costs lower.

- Q:Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- Light steel keel is above the keel, the ceiling should use keel, gypsum board ceiling also use keel, generally with wood keel, of course, can also use light steel keel friends, to say that the price is light steel keel expensive.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stud of Zinc Galvanized Stud of Zinc Galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords