Metal Construction Materials Hot-Dipped Galvanized Light Steel Keel or Decorative wall panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge

etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

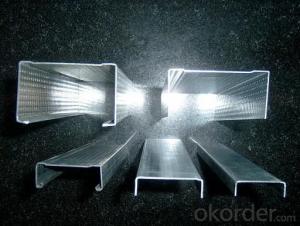

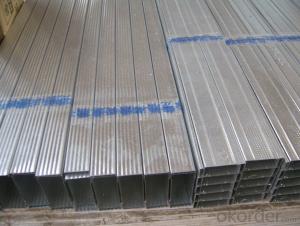

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

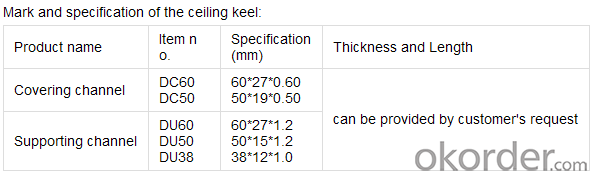

- Q:Ceiling light steel keel 50/60 in 60 on behalf of what

- Specifications model ah main keel 50 is 50 × 15 × 1.2 60 is 60 × 27 × 1.2

- Q:Light steel keel moisture-proof gypsum board ceiling which is the grass-roots which is the surface layer?

- Grass is the light steel keel, the surface layer is moisture gypsum board.

- Q:What is the keel of the aluminum veneer, or the angle welded frame?

- Aluminum veneer curtain wall using high-quality high-strength aluminum alloy sheet, its structure mainly by the panel, ribs and angle code composition. Corner can be directly from the panel bending, stamping, but also in the panel of the rivet on the corrugated angle forming. The stiffener is connected to the aluminum foil after the plate, making it a solid whole, greatly enhancing the strength and rigidity of the aluminum veneer curtain wall, ensuring the smoothness and wind resistance of long-term use. Many types of veneer, alien is the most, and some are less than keel, indoor ceiling is generally hooked board, the use of steel keel, length of 3 meters

- Q:Light steel keel gypsum board ceiling lamp how to install

- This is not the most basic process? Cutter to open the downlight to buy the LED is the external spotlight effect is kind ~

- Q:Light steel keel gypsum board ceiling need floor?

- Owners have money to do the second floor

- Q:Home decoration living room ceiling (light steel keel or wood keel) between the two, what is the difference?

- Light steel keel ceiling, from the small area of the process is harder than the wood keel, but the high flatness

- Q:Wood keel and light steel keel were used for where?

- Light steel keel main use in a large area of the ceiling, the general home decoration in addition to kitchen and steel is used outside the light keel are used wood keel. Be sure to pay attention to full brush fire retardant coating.

- Q:Ecological wood veneer gypsum board closed light steel keel ceiling decoration drawings so what is the meaning? How to understand

- The gypsum board closed should refer to the ceiling, behind the "light steel keel" is "special" indicate that the use of the ceiling required to use the "green gauze board" Keel is "light steel keel".

- Q:Light steel keel gypsum board ceiling is good, or sauna board, integrated ceiling buckle board good?

- Cost, gypsum board hanging flat top cheap! Performance is the best integrated buckle ceiling! Deformation coefficient is small! But the bedroom is no water! Suggestions or use light steel keel to hang! When loading the lights to hang on the keel! Light steel keel gypsum board ceiling about 70 per square meter it!

- Q:Light steel keel gypsum board modeling ceiling

- Light steel keel ceiling, is that we often see the ceiling, especially the shape of the ceiling, are made of light steel keel frame, and then covered with gypsum board made. Light steel keel ceiling according to load is divided into human light steel keel ceiling and not on the light steel keel ceiling. Light steel keel according to keel section can be divided into: U-keel and C-keel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metal Construction Materials Hot-Dipped Galvanized Light Steel Keel or Decorative wall panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords