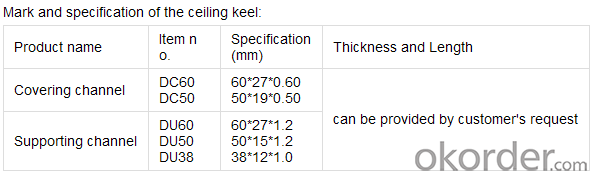

Ceiling Drywall Setal Stud &Furring Profile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge

etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

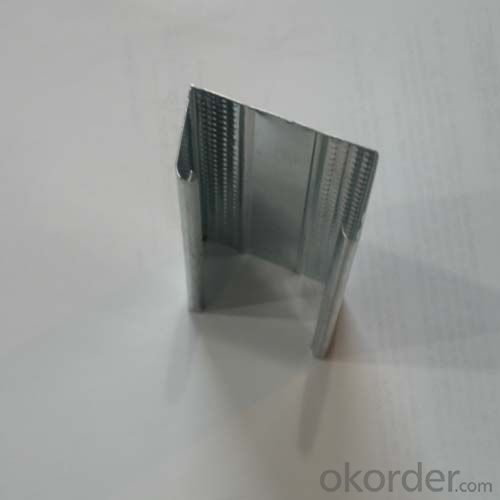

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q:Wood keel expensive or light steel keel expensive?

- Good wood keel is more expensive than the green keel But generally do not use a good keel Wood keel and light steel keel in the price is actually not much difference We used to use wooden keel because it is better than light steel keel point Light steel keel bad shape, many are reluctant to use But I still recommend that you use light steel point, fire and moisture anti-deformation

- Q:Light steel keel will rust?

- Yes ah, when I installed the ceiling to experience, before and after the attitude of a comparison, too ridiculous, and feelings they are learning Sichuan play face it

- Q:Light steel keel ceiling cad chart

- There is a special light steel keel construction of the chart to sell, you can buy a set, only tens of dollars, inside the various forms of light steel keel ceiling, partitions have detailed construction techniques and regulatory requirements

- Q:Light steel keel ceiling cracks how to deal with

- There are many reasons for the cracking of the roof, and the repair of cracks caused by different causes is not the same. Therefore, after the cracks, the first should be how the cracks are generated, to identify the problem of pipe fittings, and then develop a rest plan, should not blindly construction. Otherwise it may fall into a crack, make up the vicious cycle of the process. There are three main reasons and treatment methods: 1, the surface of the paint surface cracking repair If only the ceiling film to generate linear, multi-angle or irregular cracks, then the problem is not very serious. The reason may be due to a brushing too thick or dry re-coated, the substrate is too loose or rough, primer and paint is not matched and so on. Repair measures: to eliminate the affected film; to ensure that the film is not a very thick construction; to ensure that the front paint dry after re-coating; if necessary, with the appropriate primer to seal the substrate; for roughness of the substrate, The use of good flexibility of the product; substrate temperature below 5 ℃, not construction latex paint; primer and finish to match. 2, the temperature changes caused by the ceiling cracking If it is due to temperature changes caused by cracking, generally appear in the surface, will not affect the safety of the ceiling, the surface can be processed about. 1, the gap is not: If the surface gap is not large, it is recommended in the gap posted a layer of kraft paper, and then brush the surface coating. 2, the gap is wide: If the surface gap is wide, then it is best to cut out a piece of gypsum board, polished into the appropriate shape, fill in the gap, and then brush the finish paint. 3, improper construction caused by the ceiling cracking if it is because the ceiling frame, gypsum board finishes, etc. ...

- Q:Light steel keel ceiling The first main keel distance from the wall should be how much? To be specific.

- Thirty centimeters This is the standard necessary distance

- Q:Light steel keel ceiling hidden information, including what ah

- Keel, hanging bars, other accessories and other quality to meet the design requirements and related norms, to have the relevant certificate and test reports, and a few copies;

- Q:Light steel keel ceiling which brand is better

- Domestic dragon card can, foreign brands have Lafarge, Jieke is also good. Above, not advertising, on the matter only - the landlord itself is to do building materials, should not know it?

- Q:Light steel keel ceiling do anti-support angle iron how fixed on the main keel, how fixed on the ceiling surface?

- When installing the support material, use the angle iron to drill the hole first in the angle iron, and then use the wire to the angle iron can be tied to the hanging bar, do not need to fix it on the ceiling, the length of the support material, generally to support Of the ends of the hanging ends of not less than 20 cm can be. For example, if the length of the hanging bar is 2 meters, then the length of the support should not be less than 1.60 meters on the two ends of the average points on the line.

- Q:Do you need to leave a gap between the ceiling and the wall? If you need to stay much in line with design requirements? Need to do those deals

- Light steel keel manuscript board ceiling and the need to stay between the wall, leaving 5MM is enough

- Q:What is the general ceiling of indoor ceiling?

- Upstairs copy of the good. Really quite detailed. That I also talk about it. Light steel keel wood keel aluminum buckle plate steel plate plaster board sauna board

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceiling Drywall Setal Stud &Furring Profile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords