Australia And New Zealand Drywall Metal Stud for Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories, office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

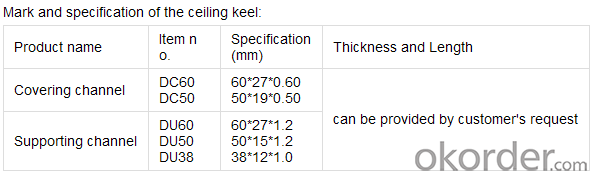

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q:Why the ceiling keel

- Ceiling keel is what we often see the ceiling, especially the shape of the ceiling, are made of keel frame, and then covered with gypsum board made. Ceiling keel is made of light steel, for the ceiling of the main material, it is connected with the floor through the screw, used to fix the ceiling or objects.

- Q:Do not know the price of light steel keel home improvement, it is best to use the North New Building materials dragon card. Have to know the friend thread, thank you!

- I said there are specifically to do light steel keel construction of individuals or units, small point of the decoration company eventually have to find these people, unless the big decoration company dedicated to keep a gang. Light steel keel home ceiling and wood keel compared to the very troublesome, but the quality is better, of course, the cost is high, this I was psychologically prepared. Have to do the same friends can stand short me, thank you.

- Q:Light steel keel ceiling cad chart

- Light steel keel ceiling with flat top, modeling ceiling, down the ceiling, etc., to your not necessarily for you.

- Q:Light steel keel ceiling specifications require boom length greater than 1500MM to add anti-support, what is anti-support? How to set up? The best specific construction node map, thank you!

- I do not understand what you ask, I am a dragon brand building materials dealers, what do not understand you can also call the dealer.

- Q:Ceiling twenty square meters need light steel keel how many roots

- Light steel keel ceiling material ratio does not have a standard number, generally according to the shape of the room, height related.

- Q:Light steel keel ceiling boom and whether the strong electric lines can be common

- Construction regulations are not allowed.

- Q:Tectonic hierarchy of light steel keel

- Operating conditions 1. Construction of the structure should be in the cast-in-place concrete floor or prefabricated concrete floor slab, according to the requirements of the radio, according to the embedded φ6 ~ φ10 reinforced mixed boom, shot without the requirements of the arrangement of large keel location embedded steel hanging Rod, the general spacing of why 900 ~ 1200mm. 2. When the wall of the ceiling room for the brick masonry, the elevation should be in the ceiling along the walls and columns around the masonry embedded wood preservative, along the wall spacing 900 ~ 1200mm, the column should not be buried on each side More than two pieces of wood. 3. Install the roof of the various pipelines and ventilation ducts, to determine the light, ventilation and a variety of exposed mouth position. 4. All kinds of materials all ready to prepare. 5. Ceiling cover panel should be installed before the wall, wet operation project. 6. Take the roof construction platform. 7. Light steel skeleton roof in a large area before the construction, should do the model between the roof of the crown, lamp, vents of the tectonic treatment, block and fixed methods should be tested and approved by the approved before the big Area construction.

- Q:Construction schedule of light steel keel ceiling

- Two woodworking a painter, measuring the elastic line, punching the security boom, the main, the second keel day, adjust the reinforcement keel, install the gypsum board, screw rust treatment, paste kraft paper (caulking) one day. Putty (at the end) playing sandpaper on the wall paint (three at the end of both sides), a total of five days, two carpentry two days, four days of paint workers.

- Q:Light steel keel and wood keel ceiling unit area of the amount of material how to calculate?

- Light steel keel ceiling ratio is: the main keel is 1: 1.1 (per square meter ceiling main keel is 1.1 meters), vice keel is 1: 3.5, the main hanging pieces 1: 1, 1, Hook 1; 3.5, the remaining accessories (main then, vice, support, screw, burst nails), etc. is 1. Wood keel ceiling ratio is: 3 * 4 wood side 1: 5.5 (including the use of boom), the rest is nails and other hardware. Gypsum board is basically 1: 1.1 (modeling should be open).

- Q:Attic light steel keel gypsum board ceiling construction drawings how to draw?

- To draw one or several sections, to express the steeple tilt angle and internal structure (light steel keel plus gypsum board) on the line

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Australia And New Zealand Drywall Metal Stud for Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords