Drywall Metal Studs and Tracks Drywall Metal Studs and Tracks

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories, office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

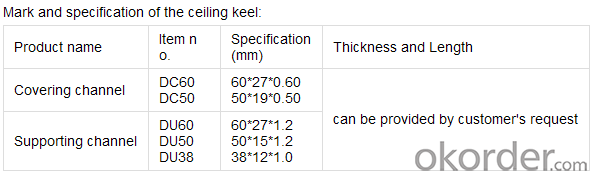

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q:I help people pull the line, to climb the ceiling, but the ceiling of the light steel looks thin, you can climb up? Afraid! I am now 120 pounds.

- The ceiling of the keel is divided into three kinds of specifications, two kind of not a man, a master, the man you stepped on the keel walking certainly no problem, not on the following 150 pounds can go, but the premise of his Keel must meet the national norms, wall thickness of 1.2mm or more.

- Q:There are several specifications for light steel keel with household ceiling

- Decorative materials Light steel keel models are 50, 75, 100, 150 and several other, and the thickness of light steel keel from 0.4mm to 2.0mm range. The ceiling keel consists of the main keel, auxiliary keel and various accessories. D38 (UC38), D50 (UC50) and D60 (UC60) three series. D38 for hanging point spacing 900-1200 mm not on the ceiling, D50 for hanging point spacing 900-1200 mm Master ceiling, D60 for hanging point spacing 1500 mm Master heavier ceiling, U50, U60 for the cover keel, it With the use of keel. Wall keel consists of horizontal keel, vertical keel and cross brace and various accessories, there are Q50 (C50), Q75 (C75), Q100 (C100) and Q150 (C150) four series.

- Q:Light steel keel ceiling price 60 level probably need much money

- A square about a hundred or so package materials

- Q:PVC plastic buckle plate ceiling with what keel ah?

- PVC gusset plate should be used "head" word dragon skeleton, keel spacing of 400mm-600mm, suspended skeleton to add boom, spacing 1m. Aluminum gusset used keel should be supporting keel, dragon keel spacing of 600mm, fixed boom should be supporting the simple telescopic boom to prepare for the adjustment of the dragon skeleton. Now the basic use of aluminum buckle plate plastic buckle plate market is rare to recommend the use of aluminum plate.

- Q:How to pick the ceiling keel

- Such as dragon brand keel keel with light weight, high strength, good corrosion resistance, etc., can be used as a lightweight partition skeleton material, mainly with the plaster board and its products supporting the use of other plates can also be used: GRC board , FT board, Ed board and other materials supporting the use of.

- Q:Will the light steel keel ceiling be deformed?

- Generally not Please adopt If you acknowledge my answer, please accept it in time, ~ If you acknowledge my answer, please click on the "Accept Satisfactory Answer" button ~ ~ Mobile phone questions friends in the upper right corner of the client evaluation point [satisfaction] can be. ~ Your adoption is the driving force of my progress ~ ~ O (∩ _ ∩) O, remember praise and adoption, help each other

- Q:Will the light steel keel ceiling area is small can be no boom?

- Do not meet, must be installed boom, side keel fixed must be,

- Q:Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- Construction Measures of Caustic Sintered Calcium Silicate Board Ceiling 1, the roof height level: according to the level of the floor level, with the vertical bar to the ceiling design elevation, along the wall to the surrounding height of the ceiling. 2, designated keel file line: according to the design requirements of the primary and secondary keel spacing arrangement, has been on the roof of the standard elevation of the keel sub-line. 3, the installation of the main keel boom, playing a good ceiling elevation and keel sub-file position, to determine the boom under the head of the elevation, according to the main keel location and hanging spacing, the end of the bucket without screw button embedded with the floor expansion Bolt connection is fixed. 4, install the main keel 1> equipped with boom pheasant 2> Install the pendant on the main keel 3> Install the main keel: the main keel will be assembled hanging pendant, according to the location of the sub-line to hang the hanging pieces into the corresponding ring bolt. 4> main keel connected with the installation of connectors, pull the line to adjust the elevation, from the arch and straight. 5> around the keel with nailing Hong set. Design no request, the nail spacing of 1000mm.

- Q:Light steel keel ceiling The first main keel distance from the wall should be how much? To be specific.

- Thirty centimeters This is the standard necessary distance

- Q:What kind of size of the ceiling?

- Ceiling with wooden keel is generally 3 * 4CM, light steel keel used rarely used for home improvement, specifications are generally 50, 38 two series models!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Metal Studs and Tracks Drywall Metal Studs and Tracks

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords