Steel Frame Formwork for Column Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Column Steel Frame Formwork Description

With adjustable flexiable sizes of frame, the column steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean with column formwork. As the framework, it is adapted to the plywood with thickness of 18mm. High-precision production line guarantees the perfect products.

2. Main Features of Column Steel Frame Formwork

◆ Allowable pressure is 80KN/m2 .

◆ Faster and easy operation.

◆ The dimension for column is adjustable.

- We can special design according to any requirements.

3. Column Steel Frame Formwork Specifications

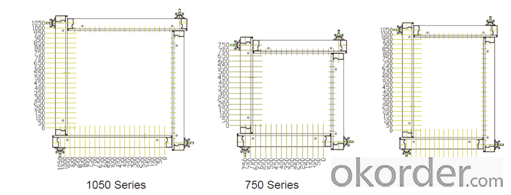

4. Column Steel Frame Formwork Images

5. FAQ of Column Steel Frame Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q:Can steel frame formwork be used in areas with limited access?

- Yes, steel frame formwork can be used in areas with limited access. Steel frame formwork is known for its versatility and adaptability, making it suitable for various construction projects, regardless of the accessibility of the area. Its modular design allows for easy transportation and assembly, enabling it to be used in tight spaces or areas with limited entry points. Additionally, steel frame formwork can be dismantled and reassembled quickly, making it ideal for projects in areas where access is restricted or challenging.

- Q:How does steel frame formwork contribute to the overall safety of a construction site?

- Steel frame formwork contributes to the overall safety of a construction site in several ways. First and foremost, steel frame formwork provides a sturdy and durable structure that ensures the stability and integrity of the concrete being poured. This prevents any potential collapses or accidents during the construction process, thereby safeguarding the workers and the entire site. Additionally, steel frame formwork is designed to be easily assembled and dismantled, reducing the time and effort required for construction activities. This not only improves productivity but also minimizes the exposure of workers to potential hazards and risks associated with prolonged construction periods. Moreover, steel frame formwork is highly resistant to fire and extreme weather conditions, making it a reliable choice for construction projects. This durability and resilience significantly enhance the safety of the construction site, as it reduces the likelihood of accidents caused by structural failures or material weaknesses. Furthermore, steel frame formwork is often equipped with safety features such as handrails and guardrails that provide additional protection to workers. These safety measures prevent falls from heights and ensure that the workers can move around the site safely. Lastly, steel frame formwork is designed and engineered to withstand heavy loads and pressures, eliminating the risks of structural failures during the concrete pouring process. This ensures that the construction site remains secure and stable, minimizing the chances of accidents or injuries to workers. In conclusion, steel frame formwork plays a crucial role in ensuring the overall safety of a construction site. Its robustness, ease of assembly, resistance to fire and extreme weather, incorporation of safety features, and ability to withstand heavy loads all contribute to creating a secure and hazard-free environment for workers.

- Q:Steel frame wood fire doors and steel doors is a concept

- Steel wood fire doors that wood fire doors. The door is made of double layer board, which is coated with a galvanized iron sheet or a double layer wood board with a single side of a gypsum board, and a double layer board and a double layer of asbestos can be used. The new standard fire door fire door provisions of steel wood burning wood or difficult burning wood products making door frame and door frame, door panel, door fire insulation materials filling material is non-toxic and harmless to the human body and steel, and with fire hardware fittings with certain refractory properties of the door. The fire resistance of the fire doors are above 1.2H.

- Q:How does steel frame formwork compare to other types of formwork in terms of cost?

- Steel frame formwork is generally more expensive compared to other types of formwork, such as timber or aluminum. However, it offers several advantages that can offset the higher initial cost. Steel frame formwork is highly durable, reusable, and provides better strength and stability. Additionally, it requires less maintenance and can be assembled and disassembled quickly, saving time and labor costs in the long run.

- Q:What is the maximum load capacity of steel frame formwork?

- The maximum load capacity of steel frame formwork can vary depending on various factors such as the design, dimensions, and quality of the steel used. However, in general, steel frame formwork is known for its high load-bearing capacity. It is designed to withstand heavy loads during concrete pouring and formwork support. Typically, steel frame formwork can handle load capacities ranging from 60 to 100 kilonewtons per square meter (kN/m²). This load capacity allows it to support the weight of concrete, reinforcement, and any additional loads applied during construction. It's important to note that the load capacity can be influenced by factors like the thickness of the steel frames, the spacing of the supports, and the quality of the welds. Additionally, the load capacity may also depend on the specific application and the engineering calculations performed for that particular project. Therefore, it is crucial to consult the manufacturer's specifications and guidelines to determine the maximum load capacity of a specific steel frame formwork system. Additionally, consulting with a structural engineer or a qualified professional can provide more accurate information regarding the load capacity based on the specific project requirements.

- Q:Are there any limitations to the number of pour cycles for steel frame formwork systems?

- The number of pour cycles for steel frame formwork systems has certain limitations that should be taken into account. To begin with, the overall durability of the formwork system can be affected by the number of pour cycles. As each pour cycle occurs, the formwork undergoes pressure and weight from the concrete, resulting in wear and tear over time. This repeated loading and unloading of the formwork can cause deformation, bending, or even cracking of the steel frames. Moreover, the quality of the concrete surface may be compromised after multiple pour cycles. Each pour cycle introduces the possibility of imperfections such as honeycombing, bug holes, or surface irregularities. These imperfections can accumulate with subsequent pour cycles, leading to a less smooth and visually appealing finish. Additionally, the process of stripping and re-assembly can become more time-consuming and labor-intensive as pour cycles increase. As the formwork system ages, its components may not fit together as tightly or securely, making it difficult to remove or align the formwork properly for the next pour. Consequently, this can slow down the construction process and increase the risk of errors or accidents. Furthermore, the load-bearing capacity of the formwork system may decrease over time. The repeated stress and strain from multiple pour cycles can gradually weaken the steel frames, reducing their ability to support the weight of the concrete. As a result, the safety of the structure may be compromised, necessitating more frequent inspections or reinforcement measures. In conclusion, while steel frame formwork systems offer advantages in terms of strength and reusability, it is important to recognize the limitations regarding the number of pour cycles they can effectively withstand. Considerations such as durability, concrete surface quality, ease of stripping and re-assembly, and load-bearing capacity can all be influenced as the formwork system ages. Therefore, careful planning is necessary to ensure the successful and safe completion of construction projects.

- Q:How does steel frame formwork affect the overall weight of a construction project?

- The overall weight of a construction project can be significantly affected by the use of steel frame formwork. In comparison to traditional timber formwork, steel frame formwork generally weighs much less. This decrease in weight brings about a number of advantages. Firstly, it simplifies the transportation and handling of the formwork, making it more efficient. The steel frame formwork can be easily taken apart, transported, and put back together at different locations. This is particularly beneficial for large-scale construction projects that require frequent repositioning of the formwork. Secondly, the lighter weight of the steel frame formwork enables a faster and more streamlined construction process. Construction workers can easily lift and move the lighter formwork, allowing for quicker installation and removal. This efficiency leads to shorter construction times and lower labor costs. Furthermore, the reduced weight of the steel frame formwork positively impacts the load-bearing capacity of the overall structure. By decreasing the weight of the formwork, more of the load-bearing capacity can be allocated to the actual building materials, such as concrete or steel beams. As a result, the construction becomes sturdier and more efficient, with enhanced durability and safety. In conclusion, the use of steel frame formwork significantly reduces the weight of a construction project, resulting in easier transportation, faster construction, and improved load-bearing capacity. Its lightweight nature contributes to the overall efficiency, cost-effectiveness, and quality of the construction process.

- Q:How does steel frame formwork contribute to the overall safety of construction sites?

- Steel frame formwork contributes to the overall safety of construction sites by providing a sturdy and stable structure for concrete pouring. Its robust construction ensures that the formwork can withstand the weight and pressure of the concrete, reducing the risk of collapse or accidents. Additionally, steel frame formwork allows for precise and accurate placement of concrete, minimizing the chances of structural defects or weaknesses. Moreover, its reusable nature reduces waste and eliminates the need for frequent dismantling and construction, reducing potential hazards associated with constant formwork assembly.

- Q:Are there any specific requirements for the concrete mix used with steel frame formwork?

- Yes, there are specific requirements for the concrete mix used with steel frame formwork. The concrete mix for steel frame formwork should have certain properties to ensure the structural integrity and strength of the construction. Firstly, the concrete mix should have a high compressive strength. This is necessary to withstand the pressure and weight of the steel frame and other loads that will be imposed on the structure. The specific compressive strength requirement will depend on the design and intended use of the structure. Secondly, the concrete mix should have good workability. It should be easy to pour, compact, and shape within the steel frame formwork. This is important for achieving the desired shape and dimensions of the structure. The workability of the concrete can be improved by using appropriate admixtures such as plasticizers or superplasticizers. Thirdly, the concrete mix should have low bleeding and segregation tendencies. Bleeding refers to the separation of water from the mix, while segregation refers to the separation of coarse aggregates from the mix. These issues can lead to a non-uniform distribution of materials and affect the overall strength and durability of the structure. Proper mix design and control can minimize these problems. Lastly, the concrete mix should have adequate durability. It should be resistant to environmental factors such as freeze-thaw cycles, chemical attacks, and abrasion. This is important for the long-term performance and lifespan of the structure. The mix design should incorporate appropriate cementitious materials, aggregates, and admixtures to enhance the durability of the concrete. In summary, the concrete mix used with steel frame formwork should have high compressive strength, good workability, low bleeding and segregation tendencies, and adequate durability. These requirements ensure the structural integrity and long-term performance of the construction.

- Q:Can steel frame formwork be used for underwater concrete placement?

- Indeed, underwater concrete placement can indeed benefit from the utilization of steel frame formwork. The robust nature and durability of this system enable it to endure the immense water pressure and forces. By providing a sturdy framework, it effectively contains the fresh concrete, guaranteeing its shape and position throughout the placement process. Furthermore, the steel frame formwork can be effortlessly sealed to avoid any water leakage, thereby promoting the appropriate curing of the concrete. Nevertheless, it is crucial to consider factors such as depth, current, and other environmental conditions to ensure the construction process's safety and efficacy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame Formwork for Column Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords