Steel Fiber Copper Coated From Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

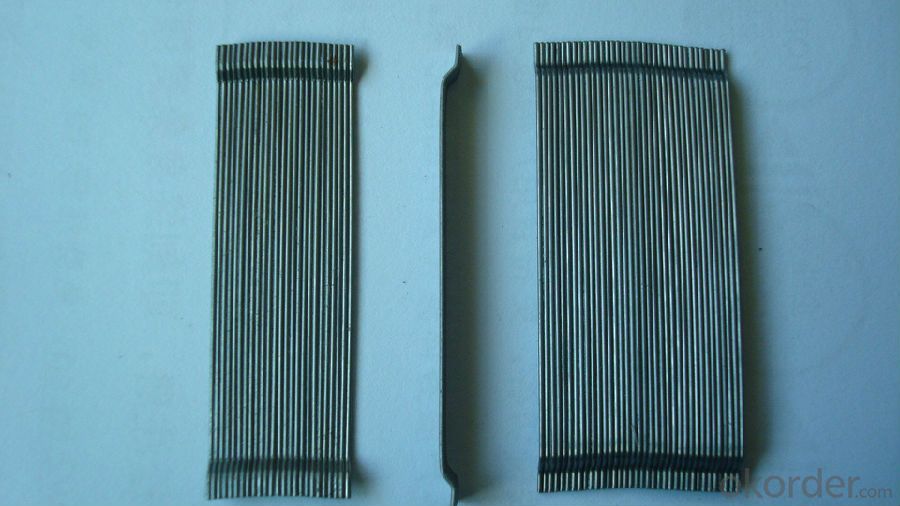

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Such steel fiber using the technology into a row of single steel fiber bonding with water-soluble glue, to ensure that the steel fiber uniformly dispersed in concret, easily stirred, eliminate agglomerate phenomena such as, due to the bonding of steel fiberrows technology, steel fibers in concrete can be evenly distributed, so that the concrete structure by the impact of steel fibers can absorb impact energy, reduce stress concentration, effectively control the emergence and development of cracks in the concrete, to extend the structural life.

As reliable and efficient concrete reinforcement material, it is widely uesd in buildings, bridges, thin roof engineering, highway etc.

In bonding steel fiber concrete internal steel fiber, as long as ramming close-grained, and air separation, steel fiber generally don't happen corrosion phenomena. Dew in the concrete surface or in the crack width more than 0.25 mm, jumper cracks in the steel fiber, vulnerable to corrosion phenomena.

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q:Can melt extract stainless steel fiber be used in industrial chimneys?

- Yes, melt extract stainless steel fiber can be used in industrial chimneys. It is commonly used as a reinforcing material in high-temperature applications due to its excellent heat resistance and durability. The stainless steel fibers can enhance the overall strength and performance of the chimney, making it suitable for industrial environments.

- Q:How does melt extract stainless steel fiber improve the durability of marine concrete?

- Melt extract stainless steel fiber improves the durability of marine concrete through several key mechanisms. Firstly, the addition of stainless steel fibers enhances the overall strength and toughness of the concrete, making it more resistant to cracking and spalling under the harsh conditions of the marine environment. These fibers act as reinforcement, providing additional tensile strength to the concrete matrix and preventing the propagation of cracks. Furthermore, the corrosion resistance of stainless steel fibers is a crucial factor in improving the durability of marine concrete. The presence of saltwater and chloride ions in marine environments can cause significant corrosion to traditional reinforcement materials like steel bars. However, stainless steel fibers are highly resistant to corrosion, ensuring the long-term integrity and durability of the concrete structure. Another important benefit of melt extract stainless steel fiber is its ability to enhance the resistance of marine concrete to impact and abrasion. The fibers act as a sacrificial layer, absorbing and dissipating the energy of impacts, such as waves or floating debris, which could otherwise cause damage to the concrete surface. This results in a more durable concrete structure that can withstand the harsh conditions of marine environments over an extended period. In addition to these mechanical properties, melt extract stainless steel fiber also improves the durability of marine concrete by reducing shrinkage and improving the overall dimensional stability. This is particularly important in marine applications where the concrete is exposed to wet-dry cycles and extreme temperature variations. By minimizing shrinkage and reducing the potential for cracking, stainless steel fibers contribute to the longevity of the concrete structure. Overall, the incorporation of melt extract stainless steel fiber in marine concrete significantly enhances its durability by improving strength, corrosion resistance, impact resistance, and dimensional stability. These properties ensure that the concrete can withstand the demanding conditions of marine environments, leading to longer service life and reduced maintenance costs.

- Q:Is melt extract stainless steel fiber compatible with different types of shotcrete curing methods?

- Yes, melt extract stainless steel fiber is compatible with different types of shotcrete curing methods. This type of fiber is often used in shotcrete applications to improve the strength, durability, and ductility of the concrete. It can be added to the shotcrete mix and sprayed onto various surfaces using wet or dry methods. Melt extract stainless steel fiber can be effectively used with different shotcrete curing methods including standard wet curing, accelerated curing, and polymer-based curing. It helps to reduce cracking and shrinkage of the shotcrete, improving its overall performance and longevity. Additionally, melt extract stainless steel fiber is highly resistant to corrosion and can withstand harsh environmental conditions, making it suitable for use in various shotcrete curing methods. It provides excellent bonding with the concrete matrix, enhancing its structural integrity and resistance to impact and abrasion. In summary, melt extract stainless steel fiber is compatible with different types of shotcrete curing methods and can significantly enhance the performance and durability of shotcrete applications.

- Q:What is the effect of melt extract stainless steel fiber on the plastic settlement of concrete?

- The effect of melt extract stainless steel fiber on the plastic settlement of concrete is that it helps to reduce the settlement and improve the overall stability and durability of the concrete. The fibers are dispersed throughout the concrete mixture, providing reinforcement and improving its resistance to cracking and shrinkage. This results in less plastic settlement and a more robust concrete structure.

- Q:What is the recommended fiber length for melt extract stainless steel fiber in concrete?

- The recommended fiber length for melt extract stainless steel fiber in concrete typically ranges from 25mm to 50mm. This fiber length is considered optimal for enhancing the mechanical properties and durability of concrete. It helps to improve the tensile strength, flexural strength, and impact resistance of the concrete, making it more resistant to cracking and improving its overall performance. Additionally, this fiber length ensures proper dispersion and distribution within the concrete matrix, leading to a more uniform reinforcement throughout the structure. However, it is important to note that the specific fiber length may vary depending on the specific application and design requirements, so consulting with a structural engineer or following manufacturer guidelines is recommended.

- Q:Can melt extract stainless steel fiber be used in architectural precast cladding?

- Yes, melt extract stainless steel fiber can be used in architectural precast cladding.

- Q:Can melt extract stainless steel fiber be used in precast bridge column elements?

- Yes, melt extract stainless steel fiber can be used in precast bridge column elements. It is commonly used to enhance the mechanical properties and durability of concrete, making it suitable for high-performance applications such as bridge construction. The addition of stainless steel fibers improves the flexural strength, crack resistance, and overall structural integrity of the precast elements, making them more robust and able to withstand the demands of bridge column construction.

- Q:What is the impact of melt extract stainless steel fiber on the thermal properties of concrete?

- Melt extract stainless steel fibers have a significant impact on the thermal properties of concrete. These fibers enhance the thermal conductivity and heat transfer capabilities of the concrete. This results in improved thermal stability, reduced thermal cracking, and enhanced resistance to temperature variations. The addition of stainless steel fibers also helps in reducing thermal expansion and contraction, leading to increased durability and longevity of concrete structures.

- Q:What is the effect of melt extract stainless steel fiber on the modulus of resilience of concrete?

- The use of melt extract stainless steel fiber in concrete increases the modulus of resilience. This means that the concrete becomes more resistant to cracking and has improved energy absorption capabilities.

- Q:Does melt extract stainless steel fiber improve the resistance to carbonation in concrete?

- Concrete's resistance to carbonation can be improved by incorporating melt extract stainless steel fiber. Carbonation occurs when carbon dioxide from the atmosphere reacts with the alkaline components in concrete, resulting in a decrease in pH and corrosion of embedded steel reinforcement. The inclusion of stainless steel fibers in the concrete mix enhances its ability to withstand carbonation. Stainless steel fibers possess remarkable corrosion resistance properties, thanks to their high chromium content. This property renders them highly resistant to the acidic environment generated by carbonation. When dispersed throughout the concrete matrix, stainless steel fibers act as a physical barrier, hindering the infiltration of carbon dioxide into the concrete and reducing the extent of carbonation. Moreover, stainless steel fibers also enhance the durability and overall performance of the concrete. They contribute additional tensile strength and ductility, bolstering the concrete's resistance to cracks. Consequently, this prevents carbon dioxide from entering through cracks and minimizes the risk of carbonation-induced corrosion. To summarize, the incorporation of melt extract stainless steel fiber into concrete can enhance its ability to withstand carbonation. This, in turn, prolongs the lifespan of concrete structures while reducing the need for maintenance and repair.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Fiber Copper Coated From Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords