Stainless Steel Sheets Steel Plates 200 Series 300 Series 400 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

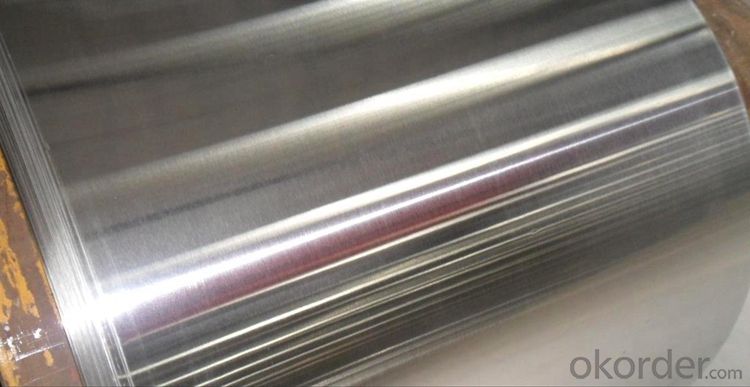

Detail picture for Stainless Steel Coils/Sheets

Application of Stainless Steel Coils

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q:Can stainless steel sheets be used for decorative panels?

- Yes, stainless steel sheets can be used for decorative panels. The versatility, durability, and sleek appearance of stainless steel make it a popular choice for various decorative applications, including panels. It can be used to create modern and stylish designs in both residential and commercial settings.

- Q:Can stainless steel sheets be cold rolled?

- Yes, stainless steel sheets can be cold rolled. Cold rolling is a process in which stainless steel sheets are passed through a series of rollers at room temperature to reduce their thickness and improve their surface finish. This process helps in enhancing the strength and hardness of the stainless steel sheets while maintaining their corrosion resistance properties.

- Q:How do you remove fingerprints from brushed stainless steel sheets?

- To remove fingerprints from brushed stainless steel sheets, you can use a microfiber cloth or a soft cloth dampened with warm soapy water to gently wipe away the fingerprints. Avoid using abrasive cleansers or scrub brushes as they can damage the brushed finish. Dry the surface thoroughly with a clean cloth to prevent water spots.

- Q:What are the different types of stainless steel sheet patterns?

- There are several different types of stainless steel sheet patterns available. Some of the most common patterns include: 1. Plain or smooth pattern: This is the most basic and simple pattern, with a smooth and flat surface. 2. Diamond pattern: Also known as tread plate or checker plate, this pattern features raised diamond-shaped ridges, providing excellent slip resistance. 3. Tear drop pattern: Similar to the diamond pattern, this pattern features raised teardrop-shaped ridges, offering enhanced slip resistance. 4. Linen pattern: This pattern resembles the texture of linen fabric, with a series of parallel lines intersected by a crisscross pattern. 5. Quilted pattern: This pattern resembles a quilted fabric, with a diamond-shaped or square-shaped design. 6. Hammered pattern: This pattern has a textured surface that resembles the marks left by a hammer, adding visual interest and dimension. 7. Perforated pattern: This pattern features small holes or perforations in the sheet, allowing for improved ventilation and drainage in certain applications. These are just a few examples of the various stainless steel sheet patterns available. Different patterns offer different aesthetic and functional benefits, allowing for greater versatility in design and application.

- Q:Are stainless steel sheets suitable for wastewater treatment plants?

- Stainless steel sheets, indeed, prove to be a suitable option for wastewater treatment plants. Renowned for its resistance to corrosion, stainless steel emerges as an optimal selection for environments characterized by excessive moisture and chemical exposure, such as wastewater treatment plants. The material exhibits an ability to endure harsh conditions and guarantee long-lasting durability. Moreover, stainless steel's ease of cleaning and maintenance proves to be crucial in a wastewater treatment facility where cleanliness and hygiene take center stage. The material's high strength-to-weight ratio further enhances its suitability for a range of applications within the plant, including tanks, piping, and equipment. All in all, stainless steel sheets undoubtedly stand as a dependable and pragmatic choice for wastewater treatment plants.

- Q:Are stainless steel sheets scratch-resistant?

- Yes, stainless steel sheets are generally scratch-resistant. Stainless steel is known for its durability and resistance to scratches, making it an ideal material for various applications, including kitchen appliances, countertops, and decorative purposes. However, it is important to note that while stainless steel is highly resistant to scratches, it is not completely scratch-proof. Sharp objects or abrasive materials can still cause scratches or scuff marks on the surface of stainless steel sheets, especially with excessive force or repeated contact. Regular maintenance and proper care can help minimize the appearance of scratches and keep stainless steel sheets looking their best.

- Q:Can stainless steel sheets be used for elevator mirrors or panels?

- Yes, stainless steel sheets can be used for elevator mirrors or panels. Stainless steel is a versatile material known for its durability, corrosion resistance, and aesthetic appeal. Elevator mirrors or panels made from stainless steel sheets provide a sleek and modern look while ensuring long-lasting performance in high-traffic areas.

- Q:Are stainless steel sheets heat-resistant?

- Indeed, stainless steel sheets possess impressive heat resistance. Renowned for their capacity to endure extreme temperatures without distorting or bending, stainless steel sheets prove to be an exceptional option for various heat-exposed purposes. The inclusion of chromium in stainless steel generates a protective coating on its surface, which effectively impedes oxidation and corrosion, even when subjected to elevated temperatures. As a result of this invaluable heat resistance attribute, stainless steel sheets are fitting for an extensive array of applications, encompassing industrial equipment, kitchen appliances, automotive components, and construction materials.

- Q:What is the density of stainless steel sheets?

- The density of stainless steel sheets typically ranges from 7.9 to 8.0 grams per cubic centimeter.

- Q:What is the price range for stainless steel sheets?

- The price range for stainless steel sheets can vary depending on factors such as size, thickness, and grade of stainless steel. Generally, stainless steel sheets can range from $20 to $200 per sheet, but prices can be higher for specialized or custom-made sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Sheets Steel Plates 200 Series 300 Series 400 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords