All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

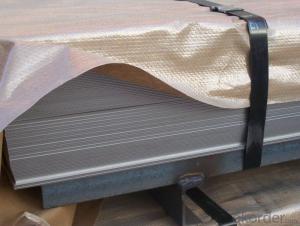

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the difference between precipitation-hardening and austenitic stainless steel?

The main difference between precipitation-hardening and austenitic stainless steel lies in their composition and the process of strengthening. Precipitation-hardening stainless steel, also known as PH stainless steel, contains elements like nickel, chromium, and copper. It gains its strength through a heat treatment process, called precipitation hardening, which involves aging at high temperatures. On the other hand, austenitic stainless steel is a non-magnetic alloy with high levels of chromium and nickel. It obtains its strength through solid solution strengthening, where the crystal structure of the steel is modified during the manufacturing process. Overall, precipitation-hardening stainless steel offers superior strength and resistance to corrosion, making it suitable for applications that require high strength and durability, while austenitic stainless steel is known for its excellent corrosion resistance and high ductility, making it ideal for various applications where toughness and formability are essential.

How is stainless steel used in the aerospace industry for the development of lightweight and fuel-efficient rocket components?

Stainless steel is used in the aerospace industry for the development of lightweight and fuel-efficient rocket components due to its exceptional strength-to-weight ratio and resistance to corrosion. It is commonly utilized in the construction of rocket engines, fuel tanks, and other structural components. The use of stainless steel helps reduce the overall weight of the rocket, enabling it to carry more payload, while its durability allows for longer service life. Additionally, stainless steel's high melting point and thermal conductivity make it suitable for withstanding extreme temperatures and efficiently dissipating heat, contributing to improved fuel efficiency and overall performance of rockets.

What are the best practices for designing stainless steel railing systems in architecture?

The best practices for designing stainless steel railing systems in architecture include understanding the building codes and regulations, considering the intended use and environment, selecting high-quality materials, utilizing proper fabrication techniques, and ensuring proper installation and maintenance. It is important to prioritize safety, functionality, and aesthetics while incorporating stainless steel railing systems into architectural designs.

Wholesale Stainless Steel from supplier in Benin

We are a Stainless Steel supplier serving the Benin, mainly engaged in the sale, quotation, and technical support services of various Stainless Steel products in the Benin region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Stainless Steel procurement services in the Benin. Not only do we have a wide range of Stainless Steel products, but after years of market development in the Benin, we can also provide valuable experience for your projects.