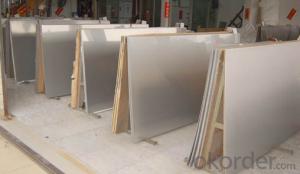

Stainless Steel 304 sheet with competitive pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q:How are stainless steel pipes manufactured?

- The production of stainless steel pipes involves a complex and careful procedure comprising several stages of fabrication and shaping. Initially, high-quality stainless steel sheets or coils are chosen and thoroughly examined for any flaws or imperfections. Subsequently, these sheets are cut into the desired dimensions. Once the sheets are cut, they are fed into a forming machine where they are rolled into the shape of a cylindrical tube. This rolling process, known as cold rolling, establishes the initial form and thickness of the pipe. The rolled sheets are then welded together using either high-frequency induction welding or submerged arc welding techniques, both of which guarantee robust and long-lasting weld joints. After the welding process, the pipe undergoes a series of finishing treatments to enhance its visual appearance and physical characteristics. Initially, excess weld material is removed using a trimming machine to achieve a smooth and uniform surface along the entire length of the pipe. Next, the pipe is subjected to an annealing heat treatment, which relieves internal stresses and improves the mechanical properties of the pipe. Additionally, annealing enhances the stainless steel's resistance to corrosion. Subsequent to annealing, the pipe may undergo additional processes such as pickling and passivation. Pickling involves submerging the pipe in an acid solution to eliminate surface impurities and oxides. Conversely, passivation involves treating the pipe with a chemical solution to create a protective oxide layer on the surface, thereby improving its resistance to corrosion. Once the finishing treatments are completed, the pipes are cut to the desired length and subjected to a final inspection to ensure quality assurance. This inspection includes checking dimensions, surface finish, weld integrity, and overall appearance. In conclusion, the production of stainless steel pipes entails a meticulous process involving cutting, forming, welding, finishing treatments, and quality control measures. This meticulous approach guarantees that the pipes meet the required standards and exhibit superior properties such as strength, durability, and resistance to corrosion.

- Q:Can stainless steel pipes be used for drinking water applications?

- Certainly, one can utilize stainless steel pipes for drinking water purposes. Stainless steel, being an exceedingly durable and corrosion-resistant substance, serves as an excellent option for conveying drinking water. Its resistance to rust, scale, and corrosion not only helps preserve the water's quality and purity but also guarantees the absence of any detrimental substances seeping into the water, thus ensuring its safety for consumption. Furthermore, the inner surface of stainless steel pipes is smooth, thereby diminishing the chances of bacterial growth and preserving the water's taste and aroma.

- Q:Can stainless steel pipes be insulated with polystyrene?

- Indeed, it is possible to insulate stainless steel pipes with polystyrene. Polystyrene, known for its exceptional thermal insulation capabilities, is widely utilized as an insulation material. Its effectiveness lies in its ability to hinder heat loss or gain from the pipes, thereby enhancing energy efficiency. Applying polystyrene insulation to stainless steel pipes can be accomplished through different techniques like pre-formed insulation jackets, spray foam insulation, or rigid foam board insulation. Nevertheless, it is crucial to guarantee the accurate installation and sealing of the insulation to prevent any potential moisture problems or harm to the pipes.

- Q:Can stainless steel pipes be used in the construction industry?

- Yes, stainless steel pipes can be used in the construction industry. Stainless steel offers many advantages, making it a preferred choice for various construction applications. Firstly, stainless steel pipes have excellent corrosion resistance, which is essential in construction projects that involve exposure to moisture, chemicals, or extreme weather conditions. This resistance to corrosion ensures the longevity and durability of the pipes, reducing maintenance and replacement costs. Furthermore, stainless steel pipes have high strength and impact resistance, making them suitable for structural applications in buildings, bridges, and other construction projects. Their strength allows for the transportation of fluids and gases under high pressure, making them ideal for plumbing and HVAC systems. Stainless steel pipes are also highly hygienic and resistant to bacteria growth, making them suitable for applications in the food and beverage industry, hospitals, and laboratories. They are easy to clean and maintain, ensuring the safety and purity of the transported materials. Additionally, stainless steel pipes have aesthetic appeal, as they can be polished to a high shine or finished in various colors, making them suitable for architectural purposes. They can be used for handrails, staircases, exterior cladding, and other decorative elements in buildings. Overall, stainless steel pipes are versatile, durable, and corrosion-resistant, making them an excellent choice for the construction industry.

- Q:What is the maximum temperature stainless steel pipes can handle?

- The specific grade of stainless steel being utilized determines the maximum temperature that can be endured by stainless steel pipes. Generally, stainless steel possesses a reputation for its exceptional resistance to high temperatures and can maintain its structural integrity within a temperature range of -150°C (-238°F) to 1100°C (2012°F). Yet, the precise maximum temperature differs depending on variables including the grade of stainless steel, the intended use, and the length of time exposed to elevated temperatures. To ascertain the maximum temperature limit for a specific stainless steel pipe, it is crucial to refer to the manufacturer's specifications and guidelines.

- Q:What is the maximum pressure rating for stainless steel pipe fittings?

- The maximum pressure rating for stainless steel pipe fittings varies depending on factors such as the size, type, and wall thickness of the fittings. It is important to refer to the manufacturer's specifications for accurate and specific pressure ratings for each stainless steel pipe fitting.

- Q:How do you calculate the expansion of stainless steel pipes?

- To calculate the expansion of stainless steel pipes, you need to consider the coefficient of thermal expansion (CTE) of the material. The CTE is a measure of how much a material expands or contracts when subjected to temperature changes. First, determine the initial length of the stainless steel pipe. This is the length of the pipe at the starting temperature. Next, determine the final temperature at which the pipe will be operating. This is the temperature at which you want to calculate the expansion. Find the CTE value for the particular grade of stainless steel used in the pipe. The CTE is typically given in units of per degree Celsius (or per degree Fahrenheit). Multiply the initial length of the pipe by the CTE value and then multiply it by the change in temperature. This will give you the expansion or contraction of the pipe in the given temperature range. For example, let's say you have a stainless steel pipe with an initial length of 10 meters, a CTE of 17 x 10^-6 per degree Celsius, and you want to calculate the expansion at a final temperature of 100 degrees Celsius. The change in temperature would be 100 degrees Celsius (final temperature) minus the initial temperature. Expansion = Initial Length * CTE * Change in Temperature Expansion = 10 meters * 17 x 10^-6 per degree Celsius * 100 degrees Celsius Expansion = 0.0017 meters or 1.7 millimeters Therefore, the stainless steel pipe would expand by 1.7 millimeters when subjected to a temperature increase of 100 degrees Celsius. It's important to note that this calculation assumes a uniform expansion along the entire length of the pipe. In reality, thermal expansion may vary due to factors such as pipe diameter, wall thickness, and other structural considerations. Therefore, it's recommended to consult with industry standards or engineering references for more accurate calculations in specific applications.

- Q:What is the difference between 304H and 304L stainless steel pipes?

- The main difference between 304H and 304L stainless steel pipes lies in their carbon content. 304H has a higher carbon content, which gives it improved high temperature strength and resistance to sensitization. On the other hand, 304L has a lower carbon content, making it more resistant to corrosion in certain environments.

- Q:What are the factors to consider when selecting a stainless steel pipe for a specific application?

- When selecting a stainless steel pipe for a specific application, there are several factors to consider. These factors include the required corrosion resistance, temperature and pressure requirements, the type of fluid or gas being transported, the pipe size and thickness, the desired strength and durability, and any specific industry standards or regulations that need to be followed. Additionally, the cost, availability, and ease of installation should also be taken into account. Overall, it is important to carefully evaluate these factors to ensure that the chosen stainless steel pipe is suitable for the intended application.

- Q:Stainless steel heating oven tube after treatment is heating blue will not be red?

- Because sometimes we do tubular heater, in order to better improve its life, will reduce the heating pipe surface power, but it itself heating speed is slow, take more time to reach the temperature you want.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel 304 sheet with competitive pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords