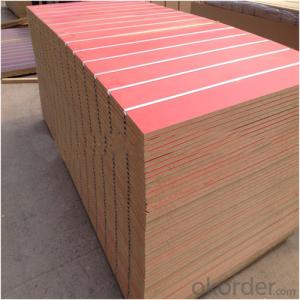

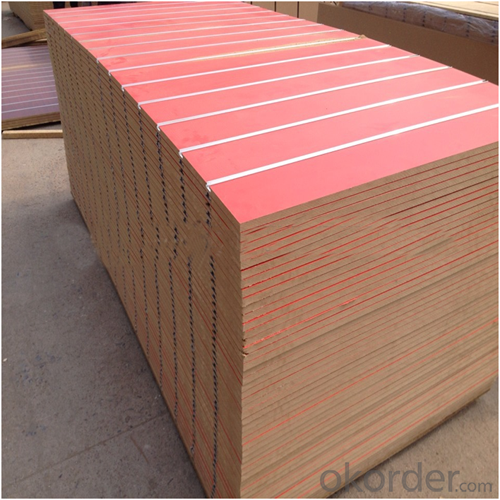

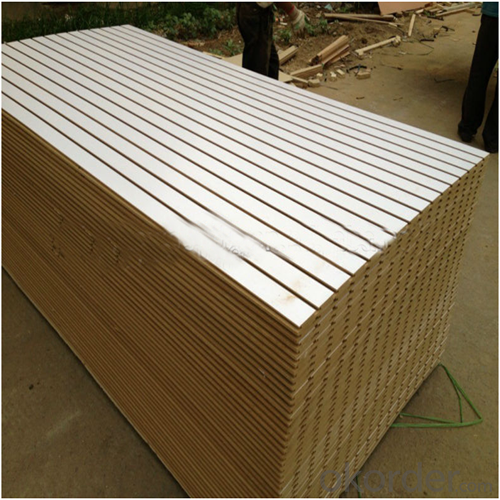

Solid Color Melamine Grooved MDF for Indoor Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 2000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Brand Name: chantaplex

· Model Number: 1220x2440

· Usage: Indoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: MDF board

· face/back: solid color and wood grain melamine paper

· core: MDF

· Glue: E2, MR,

· Fibreboard Type: MDF / Semi-hardboards

· Thickness: 2.0mm-30mm

· Grade:: First-Class

Packaging & Delivery:

The bottom is strong pallets with one sheet of protected board which is MDF or Particle board and thickness is not less than 15mm. All the goods are wrapped by plastic bags avoiding any moisture. The top and four sides with one sheet of protected board which is not less than 4mm MDF or 8mm Particle board. Then all the goods are strengthened by steel strips. The details as the following pictures

Detail Specification:

Melamine Slotted MDF

Size: | 4'x 8' (1220mm x 2440mm); 4'x 4'(1220mm x 1220mm) |

Thickness: | 15mm,16mm,17mm,18mm |

Base Wood: | MDF |

Finish: | Melamine wood grain / colorful (more than 300 colors) |

Groove: | 1220mm direction or 2440mm direction |

Packing: | wood pallets or loose |

Accessories: | Aluminium or PVC bar |

1. Aluminum Channel Inserts: provides maximum weight capacity, and decorative look.

Other colors and custom powder coating available

2. Color Snap Inserts: Plastic channel inserts that snap into already installed slatwall that give a clean finished look in over 10 colors. Installs in minutes.

3. Grooves distance: 75mm/100mm/150mm/200mm/300mm

4. Grade: E1, E2, CARB

5. Density: 700-780Kgs/M3

6. Melamine color: (More than 300 colors)

(1) Solid color: white, black, red, blue, yellow, orange, etc.

(2) Wood grain: Beech(white beech, red beech), walnut, cherry, oak, maple, etc.

7. Conformity with standard: USA CAL CARB,SGS,ISO9001:2008

8. Slotted board also named slatwall, slat wall,slotted board,grooved board and so on.

Technical Data:

No. | Test Items | Technical Specification | Unite | Test Result |

1 | Moisture Content | 4~13 | % | 5.8 |

2 | Density | 450~880 | Kg/m3 | 730 |

3 | Density Tolerance | ±7.0 | % | ±1.4 |

4 | Expansion ration in thickness due to water absorption | ≤10 | % | 8.8 |

5 | Internal bonding | ≥0.45 | Mpa | 0.49 |

6 | Modulus of rupture | ≥20 | Mpa | 26.8 |

7 | Modulus of elasticity | ≥2200 | Mpa | 3280 |

8 | Screw holding | Face≥1000 | N | 1120 |

Side≥800 | 870 | |||

9 | Surface bonding | Mpa | 1.28 | |

10 | Formal Dehyde Emission | E1: ≤9.0 | mg/100g | 4.9 |

E2: ≤30.0 | 20 |

MDF colour and material :

100% poplar material with white colour

100% pine material with light yellow colour ,

70% poplar or 70% pine mix 30% hard wood with normal colour

Product Advantage:

1. Customized Groove Type.

2. Good cutting, easy to install, No chipping

3. Famous-brand product, quality assurance

4. Uniform plate density, excellent physics performance; It's close to natural wood but better than natural plank.

5. High strength and good dimensional stability, thickness is2.5mm-30mm,it has been widely used.

6. Good mechanical processing performance, It may use natural wood processing equipment and methods for machining.

7. Flat surface,so It is easy for secondary processing.

Product Pictures:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Our value: Customers first. Honest and trustworthy, keeping our promises.

Our mission: To serve the whole world!

We are looking forward to our cooperation!

- Q:Fire rock wool color steel sandwich board 75 thick one square meter how much money?

- The price accounting for fire-resistant rock wool sandwich panels requires a number of factors, including the quality and brand of color steel sandwich panels, and whether rock wool needs hydrophobic rock wool and other factors. For specific price accounting please contact the business.

- Q:Color steel foam sandwich board is how much? Model is divided into several?

- There are two types of panels: Metal panel and non-metal panel two. Metal panels are easy to process and can be made in a variety of shapes, but in some cases non-metallic panels have the effect of metal panels, such as corrosion resistance, impact resistance and so on. Widely used in large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities room, building plus layer, clean workshop and the need to heat insulation fire places. Sandwich board shape beautiful, bright color, the overall effect is good, it sets load, insulation, fire, waterproof in one, and no secondary decoration, quick and easy installation, short construction period, comprehensive benefits, is a wide range of uses, With the potential of efficient and environmentally friendly building materials.

- Q:The thickness of the steel plate of the temporary space sandwich panel is generally thick

- There are five and seven

- Q:Housing ceiling with a good light or good sandwich panels

- Of course, light steel keel Well, first of all, wood keel easy to crack, deformation. Because the wood keel is not moisture, which easily lead to ceiling cracking, deformation, and easy to be corrosion, insects. In addition to the above problems, there are hidden dangers such as ceiling fall. Second, the wood keel strength and toughness is poor, resulting in the ceiling, partition wall life is short, and not fire, easily lead to fire. Light steel keel is a substitute for wood keel. Light steel keel with high strength, corrosion resistance, structural stability, easy to deformation and so on. Its flatness is better, the construction speed, good stability, as well as fire, moisture and other advantages, so, in order to renovate the dormant hidden, it is best to use light steel keel.

- Q:Suzhou Yanmian sandwich board which is good?

- It is recommended to consider Suzhou Fu new purification equipment Technology Co., Ltd., the company is specialized in the purification equipment R & D and production, purification engineering design, purification engineering construction, purification project maintenance clean room vacuum cleaner, laminar flow hood FFU, clean shed and electrostatic products sales Comprehensive technical services of high-tech enterprises. It can provide professional air purification system engineering design for air electronics, biomedical, hospital operating room, fiber optic cable, food and beverage, precision instrument, semiconductor and new material application, air purification system engineering, air purification system engineering inspection and air Purification system engineering and technical services; according to the customer's actual requirements and the actual needs of the design, manufacture, installation of clean room systems and equipment. So you can consider buying and cooperating.

- Q:Color plate sandwich panel 75mm, 0.

- The 75MM is the insulation thickness of the insulation board .050MM is the thickness of the insulation board with the color of the plate, the professional point should be called on the next 5, or what, is the top of the top plate thickness, the next is the next look at the house To the thickness of that side If you are the wallboard, that is, two sides are flat look, 0.50 is a side of the color plate thickness, usually outside the house to see that side, the house did not explain the thickness of the normal and outside the same thickness, Hope you can see,

- Q:I would like to ask the color steel tile sandwich panels can cover the chicken coop? Does it have a good insulation effect?

- Can be, but the traditional ceiling color steel tile sandwich panels generally composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K ) Above, plus foam and foam board between the gap, the temperature is very serious, comprehensive actual thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because the polyurethane in the construction of the use of direct spray molding technology, so that the polyurethane foam layer without patchwork as a whole to form a complete impermeability, fundamentally put an end to the possibility of deep water along the seam along the seam. Which play a preservative and waterproof effect.

- Q:Is the sandwich panel toxic? Now we live with a sandwich board to do the house, listen to friends that sandwich board toxic, is it true?

- Sandwich panels are environmentally friendly materials, how many are a bit, no big problem, you can rest assured that use. But I would like to remind is in the color of the steel house, pay attention to the improper use of the kitchen to prevent fire. For the quality of sandwich panels, the world color steel is good to understand the next.

- Q:Color steel plate wall how many meters a general support, corrugated color plate non-sandwich panels

- Is there any angle between the top and bottom of the color plate? If not, the two panels at the junction should be set up a support point. If there is, 2-3 sets of color board can be set up to support, depending on the size of the project area average annual wind. We usually set up a 2 support.

- Q:Can Caigang sandwich panels cover cottage? Is it possible to install it?

- Can, need color steel sandwich panels to find Wujiang City, the LEADER air conditioning purification equipment engaged in color steel technology research and production, sales manufacturers

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Solid Color Melamine Grooved MDF for Indoor Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 2000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords