Soft/Tight Fibre Cone Textile Winding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Application:

Soft/Tight Fibre Cone Textile Winding Machine is suitable for winding yarns on cones with even density and soft package before dyeing.

Main features:

Soft/Tight Fibre Cone Textile Winding Machine

1. Vertical yarn path design, no inflection point, yarn friction is small, less hairiness.

2. Special motor with longer axis can prevent yarn twisting, speed controlled by inverter.

3. Double points tension control system with micro motors, uniform yarn tension.

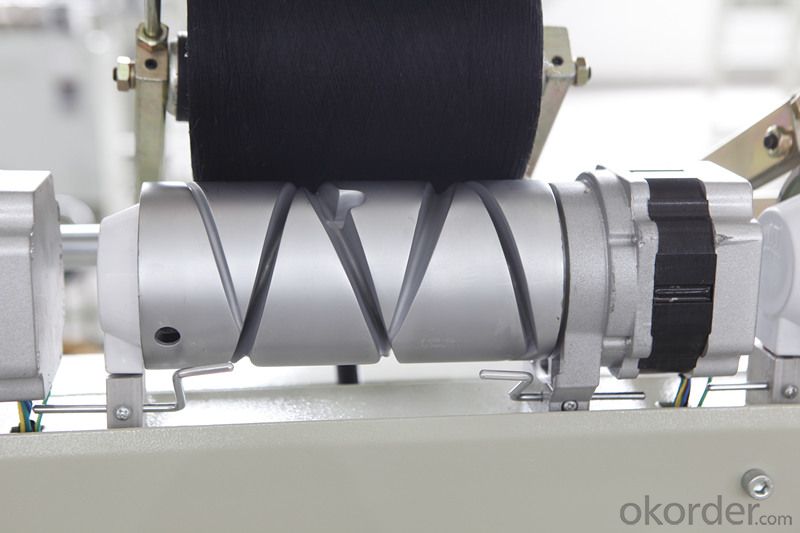

4. Using high quality alloy drums with optimized groove shape, which has the advantages of good anti-overlapping characteristics, light weight, good wear resistance, and static elimination.

5. Single winding motor control for each spindle, electronic length, single spindle automatic stop while yarn breaking or fully filled.

6. High-speed creel with gas spring, which can keep constant winding pressure. This creel is stable and reliable.

7. The traverse device for making the soft edge is very easy to adjust, that will make the loose bobbin be suitable for even dyeing.

8. There is tube conveyor on the machine, it can convey tubes and packing automatically. With it, you can not only save labor, but also keep the production site clean.

9. Our adjustable block yarn sheet metal can prevent the yarn be a mass.

Product pictures of Soft/Tight Fibre Cone Textile Winding Machine:

Delivery Pictures:

Specification:

Soft/Tight Fibre Cone Textile Winding Machine

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 800m/min |

| Package shape | Cylindrical or conical |

| Traverse length | 230mm,280mm, |

| Package bobbin | Cylindrical or conical of 3°30’ |

| package diameter | Up toφ 290 mm |

| Package density | 0.2-0.4g/cm3 |

| Package weight | Up to10kg |

FAQ of Soft/Tight Fibre Cone Textile Winding Machine:

· Q:What is the machine used for?

A: Soft/Tight Fibre Cone Textile Winding Machine is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q:What is spinning down?

- According to archaeological data, in the whole of China dozens of provinces and cities have been excavated in the early residents of the site, almost all the major parts of the spinning spindles unearthed

- Q:How to promote the textile machinery industry transformation and upgrading?

- To the production of new materials, textile machinery industry transformation, from the market in terms of new areas

- Q:Who invented Jenny spinning machine?

- In the mid-18th century, British goods were increasingly sold overseas, and the production of handmade workshops was inadequate. In order to increase production, people find ways to improve production technology. In the cotton textile sector, people first invented a shuttle called the weaving tool, greatly accelerated the speed of the weaving, but also to stimulate the demand for cotton yarn. In the 1860s, the weaver Hagreaves invented the "jenny machine" hand spinning machine. "Jenny machine" can be spinning a lot of cotton thread, greatly improving the productivity.

- Q:What are the main producing areas of Chinese textile machinery?

- Wangtai Town, a total of 175 textile machinery manufacturing enterprises, the annual production capacity of 70,000 Taiwan (sets); textile weaving enterprises 3, the annual weaving capacity of 100 million yards, 23 industrial enterprises above designated size.

- Q:What modern textile machinery?

- One is to make the whole machine. The other is the manufacture of special spare parts (such as spindle, cradle, steel collar, bead ring, knitting needle, needle cloth, heddle, stop sheet, etc.).

- Q:What are the general fixed assets of the textile industry?

- Vinylon filament spinning machine, cutting spinning roving machine, traction machine, drafting machine cutting machine

- Q:Is there a textile industry in the Qin Dynasty?

- Ancient Chinese textile and printing and dyeing technology has a very long history, as early as in the primitive society, the ancients in order to adapt to climate change, has learned to take the land, the use of natural resources as textile and printing and dyeing raw materials, and the manufacture of simple textile tools.

- Q:What is the difference between yarn spinning and ring spinning?

- Ring spinning (combing) Process: clear flowers - carding - pre-parallel - articles and rolls - combing - the first road parallel - two parallel - roving - spinning - Winding

- Q:What is a large hydraulic spinning wheel?

- Large spinning wheel and the original spinning wheel is different, its characteristics are: the number of spindle up to dozens of pieces, and the use of hydraulic drive. These characteristics make the big spinning wheel equipped with the prototype of modern spinning machinery, to adapt to large-scale specialized production

- Q:What are the related fields of textile engineering?

- Business training requirements: The students mainly learn the basic theory of textile engineering and basic knowledge, by the textile design, textile technology design and other aspects of basic training, with textile production and management of the basic ability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Soft/Tight Fibre Cone Textile Winding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords