Silicon Carbide Ceramic Foam Filters Tailored Sizes As Customers Requirement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Ceramic Foam Filter :

Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions slag and dross from the molten metal stream.

2.Main features of Ceramic Foam Filter:

◆ Excellent thermal shock resistance

◆ Good strength under high temperature

◆ Improving casting quality

◆ Reducing turbulence in gating system

◆ Tailored sizes as customers requirement

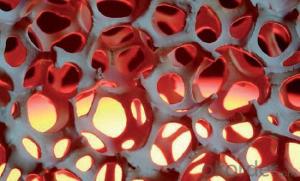

3. Ceramic Foam Filter Images:

4. Ceramic Foam Filter Technical Parameters

There are four kinds of ceramic foam filter according to different usages.

They are Silicon Carbide Ceramic Foam Filter, Zirconia Ceramic Foam Filter, Alumina Ceramic Foam Filter, Magnesia Ceramic Foam Filters.

Application

Grey iron casting, ductile iron casting, precious metals casting

Copper casting, bronze casting, brass casting

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our ceramic fiber products?

A world class manufacturer & supplier of ceramic fiber product is one

of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 80000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Ceramic filter capacity.

- You ask too general, to say processing capacity (ie capacity), at least to provide material conditions, such as: material name, concentration, particle size distribution. In addition, the basic conditions of equipment operation should be taken into account.

- Q:Working principle, ultrasonic trouble and troubleshooting of ceramic filter

- Ceramic filter is mainly composed of system, roller system, mixing discharge system, vacuum system, liquid discharge system, scraper system, washing system, cleaning system, automatic control system, and these parts body frame.

- Q:Why should filter core be used in backwash of ceramic filter?

- The filter in the water filter of ceramic filter is used for filtering water.

- Q:The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q:Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Ceramic filter plate.The ceramic filter plate does not match the blockage or selection of new plate porosity is generally around 40%, such as ceramic filter plate has hole blocking, the opening rate will become less, when the suction effect into 30% relatively new plate may be slightly worse, when the ceramic filter plate is used for a long time after the opening rate is 10% or less, then the ceramic filter plate suction effect will become very poor even suction. At this time, even if the vacuum suction is good, also do not suck sizing, you need to replace the new ceramic filter board.

- Q:The vacuum of ceramic filter is not enough

- The vacuum degree of ceramic filter is about -0.08MPa, if the ceramic filter is less than 0.06MPa, the vacuum is not enough. If the vacuum of ceramic filter is not enough, it will influence the suction effect of ceramic filter (mainly the thickness of filter cake and water content of filter cake).

- Q:What are the poor filtration effects of vacuum disc filters?

- Under normal circumstances, high vacuum, vacuum suction, high production capacity, filter cake moisture control is good. At present, some ceramic filters are equipped with two or multi-stage vacuum system to obtain almost absolute vacuum, and can reach 0.09 ~ 0.098MPa.

- Q:What happens when the pressure on the filter plate is uneven during backwashing?

- It should be said that the ceramic filter backwash, usually with a certain pressure of clean water to backwash.

- Q:Performance advantages of ceramic filter

- A ceramic filter for fine coal mud recovery, there is a base, the lower part of the frame is provided with a fine slime liquid trough, the fine slime liquid material groove is provided with a liquid level controller, the slime liquid material at both ends of the groove is provided with a negative pressure water tank, the water tank is provided with a negative pressure suction connection assembly fixing the other side is provided with a vacuum pump pipeline, the pipeline is communicated with a vacuum pump and vacuum pump;

- Q:Influence factors of ceramic filter

- (1) the particle size and the distribution of the material match the microporous of the ceramic filter plate. Although the ceramic filter plate aperture is bigger, easy to suck the pulp, but easy to cause the ceramic filter board to block up.(2) the ceramic filter plate with the same ceramic filter plate with high pore permeability and high water permeability is selected with high water permeability and good slurry absorption performance. The spindle speed is slow, the formation time of growth in the area of vacuum filter cake, production capacity increased gradually, but because the unit time of grout thickness and spindle speed slow is proportional to, so the ceramic filter capacity in a range of showing the highest.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silicon Carbide Ceramic Foam Filters Tailored Sizes As Customers Requirement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords