Ceramic Foam Filter for iron Silicon Carbide

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbide Ceramic Foam Filter for iron castings

Products confirm with China National Standard GB/T 25139-2010.

Application:For the filtration of molten Iron,copper ,aluminum and alloy.

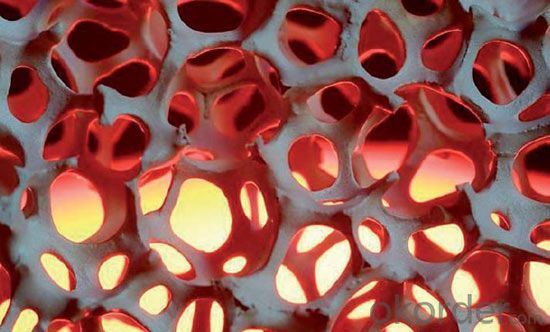

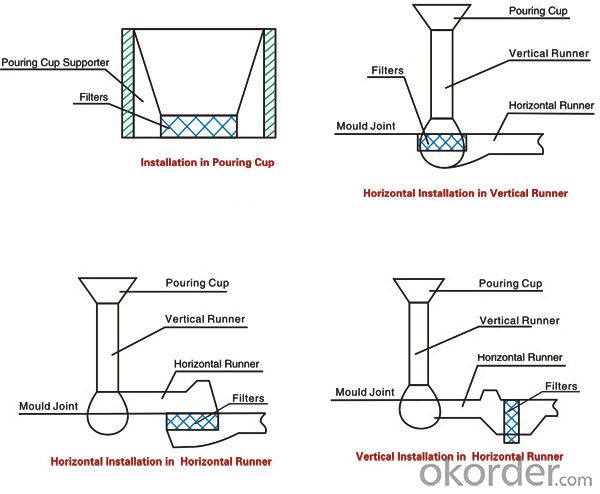

Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions including slag and dross from the molten metal stream.Additionally, they aid in reducing turbulence in the gating system.

SIC ceramic foam filter's outstanding thermal shock resistance and high strength properties were developed for superior performance in extreme iron or aluminum and copper based alloy foundry applications.

Product Features:

-Precise sizes control during filter media sponge cutting to final sinter.

-High strength with enough slurry and free from loose debris,no break and no filter slag

-Branded main raw material to ensure stable quality

-Good porosity and free from block during pouring molten metal

-Mature sintering technology to ensure high refractory and good thermal shock resistance.

Technique data:

Main material: Silicon Carbide

Max. applied temperature: ≤1500℃

Color:Gray black

Hole density (PPI):10/20/25/30(PPI=pores per inch)

Porosity(%): 80-90

High temperature bending strength(Mpa):≥2.5

Bending strength(Mpa):≥1.5

Compressive Strength(MPa) :≥1.0

Bulk Density(g/cm3): 0.43

Thermal shock resistance: 6 times/1100℃-room temp.

Dimensions:

Different sizes and PPI can be made upon customer request

Length*width*height=(35-200)*(35-200)*(10-30)mm

With round,square and rectangle shapes.Size tolerance:±1mm

Pore size: 10PPI/20PPI/25PPI/30PPI.PPI tolerance:± 2PPI

Quality assurance:

-Main raw materials are all imported branded and inspected on each procurement

-ISO 9001:2008 certified factory with strictly implementation

-Production strictly follow up National filter standard

-In process inspection on filter size,refractory and porosity

-100% inspection on every finished filters size to ensure applicability

-Authorized third party inspection certificate

- Q:Beneficiation ceramic filter no problem, the technical parameters are normal, but filter out the concentrate water suddenly excessive, what is the reason?

- The ceramic filter ceramic plate ceramic microporous pumping vacuum adsorption concentrate filtration water, the adsorption parameters according to the angle of rotation, reverse cleaning process, check whether there are loopholes in the exhaust pipe, check the ceramic plate use cycle is too long.

- Q:What about the leakage of the ceramic filter static and dynamic sealing points?

- When the main shaft is rotated, the filter cake is adsorbed on the surface of the ceramic filter plate and dehydrated by the vacuum generated by the vacuum pump.

- Q:Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- The spindle speed is too fast.The speed is too high to absorb the filter cake.There are other possible reasons.

- Q:What is the working pressure of the ceramic filter?

- Vacuum pressure or suction is the vacuum of the equipment, the size of the vacuum directly affects the effect of ceramic filter board suction (yield and water content). The vacuum system of ceramic filter consists of vacuum pumps, tanks, distribution device, ceramic filter plate and a connecting pipe is composed of ceramic filter, the vacuum pump is generally 2BV series water circulation pump, the vacuum pump vacuum limit is -0.097MPa, using a vacuum pump for a long time or vacuum system has poor sealing performance may cause a certain degree of vacuum distortion, so the ceramic filter vacuum is generally difficult to achieve in the -0.097MPa, -0.08 ~ 0.097MPa, which indicates that the vacuum degree is good, such as the vacuum degree is not up to -0.07MPa or less, the vacuum system may be an exception.

- Q:The vacuum degree of the ceramic filter is normal and the cake water is large

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

- Q:Microporous ceramic filter plate cleaning

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q:The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- Water glass is a kind of adhesive of flotation reagent, after use may cause the pulp viscosity increased, leading to the adsorption resistance of slurry becomes large, when using ceramic filter filtration dewatering, vacuum suction surface of the microporous ceramic filter plate is smaller than the resistance, there may be a suction effect or even not suction. Some flocculant agents can lead to this phenomenon.

- Q:The working principle of ceramic filter

- The working principle and mechanism and the shape of ceramic filter disk vacuum filter is similar to that in the pressure under the action of suspension by filtration medium, particles are trapped cake is formed at the surface of the medium, and the liquid through a filter medium outflow, reached the purpose of solid-liquid separation. The difference is that the filter medium of ceramic filter plate with microporous capillary effect, the capillary force in the pores is larger than the vacuum force applied to microporous keep full liquid state, no matter under what circumstances, the ceramic filter plate does not allow air through, because there is no air through solid-liquid separation, low energy consumption, vacuum a high degree of.

- Q:Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Equipment comes with cleaning:Ceramic filter comes with a combined cleaning system, usually to ensure the normal backwash water pressure, combined cleaning (nitric acid + ultrasonic + backwash) time is sufficient, sufficient amount of nitric acid.

- Q:Why does not the iron filter of the ceramic filter work?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Foam Filter for iron Silicon Carbide

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords