Self-adhesive Waterproof Membrane CMAX Brand

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Self Adhesive Bitumen Waterproof Membrane

Introduction Self-adhesive Waterproof Membrane :

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification Self-adhesive Waterproof Membrane :

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications Self-adhesive Waterproof Membrane :

-Roof and underground in industrial and civil buildings;

-Bridge, subway, tunnel, swimming pool, etc.

-Waste landfill, sewage plant, irrigation system, etc.

-Self-adhesive Modified Bitumen Waterproof Membrane

-Easy applying and economic on the cost saving

Advantage Self-adhesive Waterproof Membrane :

-Non-solidified, excellent elastic deformation,thus have good noise reducing;

-Easy applying and economic on the cost saving.

-Good performance on waterproof and economic sound damping.

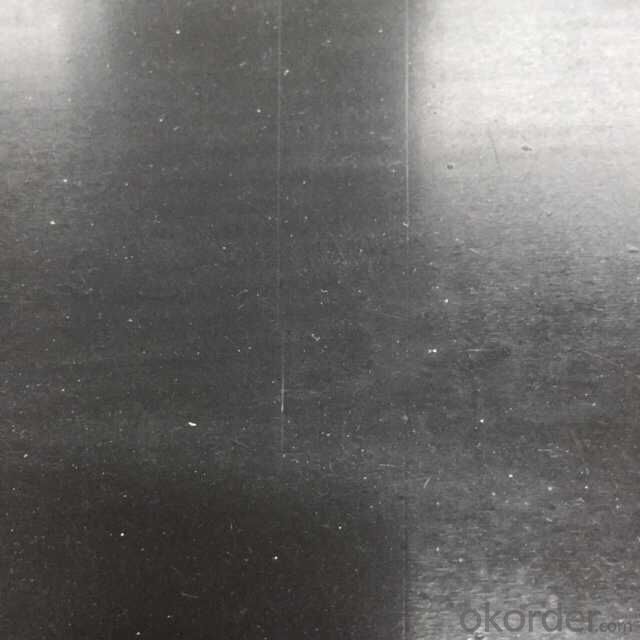

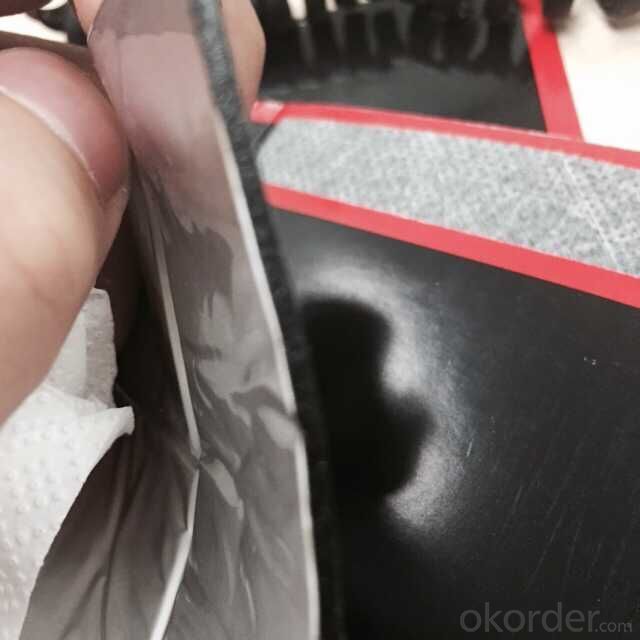

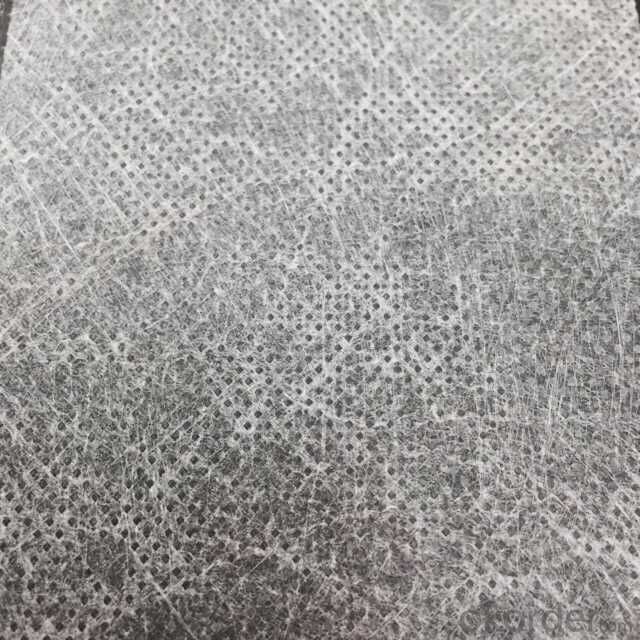

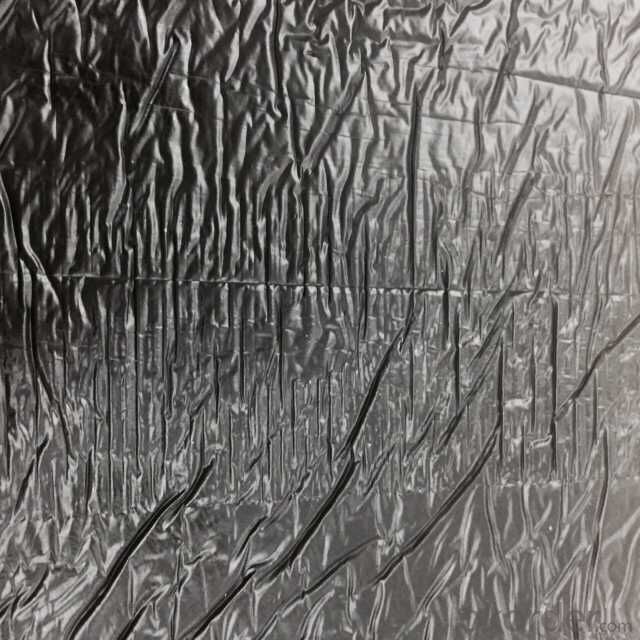

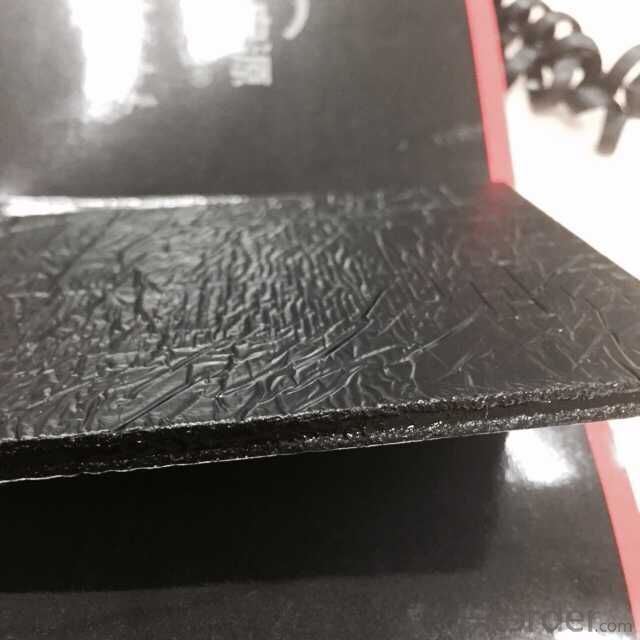

Picture:

Storage Self-adhesive Waterproof Membrane :

Shelf life is 12 months. Store in a cool and dry place with original packing.

Breathable Waterproof Roof Underlay membrane (PP-PP,S-PP,S-S)

Permeable membrane is polymer modified asphalt based, with surface of high strength polypropylene fiber. Back side coated with self adhesive glue or antiskid sand. Made by special process. With excellent waterproof performance and breathable properties.\

Description | Specification | Width | Length | Thickness | |

Roof underlay | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

Roof underlay with adhesive band | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

It is used as the underlayment of cement tile, painted pottery watts and asphalt shingle. Also suitable for all kinds of architectural roofing, walls, underground waterproof and damp proof project.

Features Self-adhesive Waterproof Membrane :

It has good waterproofing and ageing-resistance function,not flowing at highest temperature and no crack at lowest temperature;

Easy application,no pollution,and long service life etc.

Usage Self-adhesive Waterproof Membrane :

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs,basements,toilets etc;and the waterproofing of bridges,parking area,tunnels,reserviors etc.

It is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions.

Requirements for surroundings

-The base should be dry and clean. Do not work in the rainy or snowy day.

-Do not work under heavy wind(above 5 grade)

-Unsuitable for construction below 0°C

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:How does a waterproofing membrane withstand freeze-thaw cycles?

- A waterproofing membrane withstands freeze-thaw cycles by being designed with materials that can expand and contract without losing their integrity. These membranes are typically made of rubber or synthetic polymers that are flexible enough to accommodate the expansion and contraction caused by freezing and thawing temperatures. Additionally, they are formulated to resist water penetration even when subjected to these cyclical temperature changes, ensuring their effectiveness in preventing water damage.

- Q:Does a waterproofing membrane require any specialized tools or equipment for installation?

- Yes, the installation of a waterproofing membrane typically requires specialized tools and equipment. Some of the common tools and equipment used for installation include a trowel or roller for spreading the membrane, a utility knife for cutting and shaping the membrane, a heat gun or propane torch for activating and adhering the membrane, a seam roller for ensuring proper bonding of seams, and a caulking gun for applying sealant around penetrations and edges. Additionally, depending on the specific type of waterproofing membrane being installed, other tools such as a primer, bonding adhesive, or specialized membrane fasteners may be required. It is important to consult the manufacturer's installation guidelines to ensure the proper tools and equipment are used for a successful installation.

- Q:Is a waterproofing membrane resistant to abrasion?

- A waterproofing membrane is generally able to resist abrasion. Its purpose is to create a protective barrier against water and moisture infiltration. These membranes are typically constructed from durable materials like PVC, TPO, or EPDM, which possess a high resistance to abrasion. Consequently, they can endure normal wear and tear that may arise during installation or due to foot traffic or other mechanical activities. Nonetheless, it is crucial to acknowledge that the level of resistance to abrasion can vary based on the specific type and quality of the membrane, as well as the conditions in which it is employed or utilized. Therefore, it is always advisable to refer to the manufacturer's guidelines and specifications to ensure the proper selection and installation of a waterproofing membrane.

- Q:Can a waterproofing membrane be used for water tanks or reservoirs?

- Yes, a waterproofing membrane can be used for water tanks or reservoirs. Waterproofing membranes are designed to create a barrier that prevents water from penetrating through the surface. They are commonly used in various applications, including water tanks and reservoirs, to ensure that the stored water remains contained and does not leak or seep into the surrounding environment. The membrane is typically applied on the interior surface of the tank or reservoir, providing a durable and watertight seal. This helps to maintain the integrity of the water storage system and prevent any potential water loss or contamination. Additionally, waterproofing membranes can also protect the tank or reservoir from corrosion and structural damage caused by water exposure, extending their lifespan. Therefore, using a waterproofing membrane is an effective solution for ensuring the safety and functionality of water tanks or reservoirs.

- Q:Can a waterproofing membrane be used for planter boxes and green roofs?

- To ensure the longevity and functionality of planter boxes and green roofs, it is highly recommended to use a waterproofing membrane. This membrane acts as a barrier, preventing water from causing damage to the underlying structures. For planter boxes, a waterproofing membrane is crucial in order to prevent water leakage and protect the surrounding structures. Additionally, it aids in retaining moisture within the planter box, ensuring adequate hydration for the plants. Similarly, green roofs require a waterproofing membrane to prevent water from infiltrating the roof structure and causing leaks or structural damage. This membrane acts as a protective layer, facilitating proper drainage and preventing water accumulation on the roof surface. When choosing a waterproofing membrane for planter boxes and green roofs, durability, flexibility, and resistance to root penetration should be taken into consideration. Some membranes are specifically designed for these applications and offer additional features such as root barriers to prevent damage caused by plant roots penetrating the membrane. In conclusion, a waterproofing membrane is an indispensable component for planter boxes and green roofs. It serves to prevent water leakage, retain moisture, and safeguard the underlying structures from potential damage caused by water infiltration.

- Q:Can a waterproofing membrane be used for podium decks or plaza areas?

- Yes, a waterproofing membrane can be used for podium decks or plaza areas. In fact, it is often recommended to use a waterproofing membrane in these areas to protect the underlying structure from water damage. Podium decks and plaza areas are typically exposed to the elements and can be prone to water infiltration. A waterproofing membrane acts as a barrier to prevent water from seeping into the underlying layers, ensuring the longevity and structural integrity of the deck or plaza. Additionally, a waterproofing membrane can also protect the space below the deck or plaza from water damage, such as basements or parking garages. It is important to choose a high-quality waterproofing membrane specifically designed for outdoor use and to follow the manufacturer's instructions for proper installation and maintenance.

- Q:Can a waterproofing membrane be used on concrete?

- Concrete can indeed benefit from the use of a waterproofing membrane. In fact, it is a popular technique employed to shield concrete structures from the harmful effects of water and moisture. A waterproofing membrane is a slender layer of material that is carefully placed on the concrete surface, serving as a barrier against water and moisture. This membrane can be crafted from a variety of materials such as bitumen, rubberized asphalt, polyurethane, or acrylic. It is typically administered in either liquid or sheet form, effectively attaching itself to the surface and forming a continuous impermeable coating. This coating, in turn, prevents water from infiltrating the concrete, thereby thwarting the possibility of deterioration, cracks, and other types of damage. Waterproofing membranes are extensively employed in a wide range of concrete applications, including basements, foundations, roofs, and any other structures that are exposed to water or moisture.

- Q:Are there any specific tools or equipment required for installing a waterproofing membrane?

- Yes, there are specific tools and equipment required for installing a waterproofing membrane. Some of the essential tools and equipment include: 1. Protective gear: This includes gloves, goggles, and a face mask to protect yourself from any harmful chemicals or fumes. 2. Cleaning equipment: Before installing the membrane, the surface needs to be clean and free from any dust, debris, or loose particles. Therefore, you may need a broom, vacuum cleaner, or pressure washer to clean the area properly. 3. Waterproofing membrane: The specific type of membrane will depend on the project requirements, but it is essential to have the appropriate membrane material and enough coverage to ensure a proper seal. 4. Primer: In some cases, a primer may be needed to enhance adhesion between the surface and the membrane. The primer type will depend on the surface material and the membrane being used. 5. Application tools: These tools are used to apply the membrane onto the surface. Common tools include brushes, rollers, or sprayers. The choice will depend on the type of membrane and the size of the project. 6. Seam tape: If the waterproofing membrane requires seams, a seam tape will be needed to ensure a watertight seal at the joints. The tape should be compatible with the membrane material. 7. Adhesive or adhesive tape: Some waterproofing membranes require an adhesive to bond them to the surface. Alternatively, adhesive tape can be used for self-adhesive membranes. 8. Cutting tools: Depending on the shape and size of the area to be waterproofed, you may need cutting tools such as utility knives or scissors to trim the membrane to the desired size and shape. 9. Caulking gun: A caulking gun is necessary for applying sealant or caulk to fill any gaps or cracks in the surface before installing the membrane. 10. Drying equipment: After the membrane is installed, it may require a certain amount of time to dry or cure. Fans or dehumidifiers may be needed to accelerate the drying process, depending on the specific membrane and environmental conditions. It is important to consult the manufacturer's guidelines or seek professional advice to ensure you have all the necessary tools and equipment for a successful installation of the waterproofing membrane.

- Q:Can a waterproofing membrane be used in agricultural structures?

- Yes, a waterproofing membrane can be used in agricultural structures. It can help protect the structure from water damage, prevent moisture-related issues, and ensure a longer lifespan for the agricultural building.

- Q:Can a waterproofing membrane be used for underground parking structures?

- Yes, a waterproofing membrane can be used for underground parking structures. Waterproofing membranes are commonly used in construction to prevent water infiltration and protect the structure from moisture damage. In underground parking structures, where there is a higher risk of water seepage due to the location below ground level, a waterproofing membrane can be applied to the walls, floors, and ceilings to create a barrier against water intrusion and ensure the longevity and integrity of the structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Self-adhesive Waterproof Membrane CMAX Brand

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords