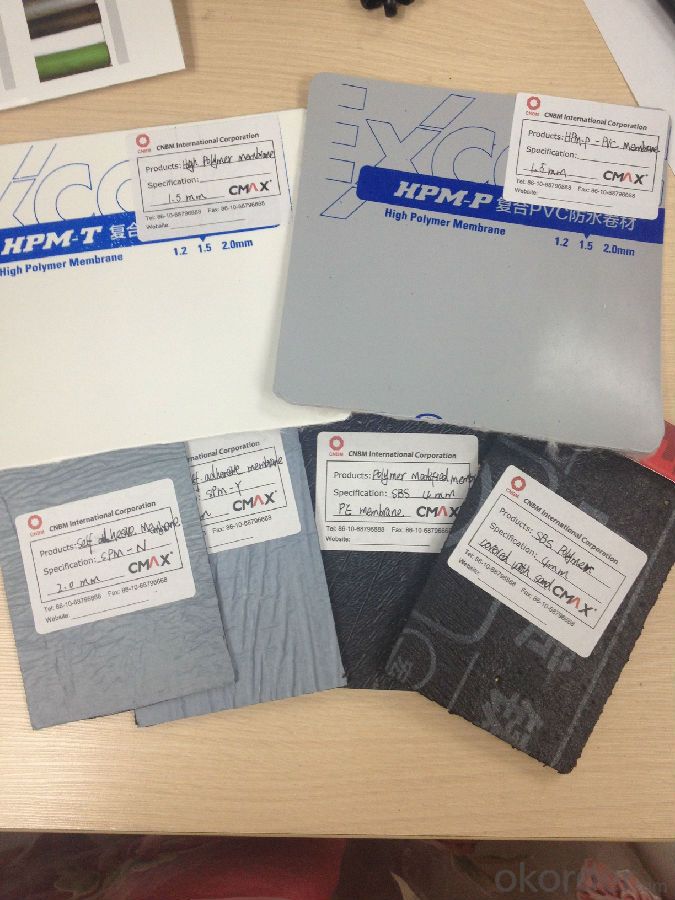

SBS Elastomeric Polymer Bitumen Waterproof Roofing Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick DetailsType:

Waterproof Membrane, Waterproof membrane Place of Origin: China (Mainland)

Surface film: PE, SAND, SCHIST,aluminum Thickness: 2.0mm~5.0mm Length: 10.0m

Width: 1.0m Usage: waterproofing for roof, understand,etc

Packaging & DeliveryPackaging Details: 10 sq.m./roll export package or as requirment

Delivery Detail: 15 days after receipt of deposit.

Specifications3mm SBS modified bitumen waterproof membrane

1) 2--5mm

2) Base:PY/G

3) Surface:PE / S / M / Al

No crack

a Only applicable to single mechanical fixed membrane construction way

B Only applicable to mineral surface bitumen waterproof membrane

C Only applicable to hot melt construction of membrane

Features

Good ability of anti-aging, anti-alkali, resistant to high temperature. High tensile strength and enlongation, which adapts to the contraction or crack of the base.

Application:

1. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. start application till it is dry.< span="">

2. Application Method:

Heating the bottom surface of membrane and the roof deck surface by flam spray gun or other suitable appliances till the asphalt start to melt(not flowing), then spread. Using roller to compact the membrane so that it can firmly adhere to the base surface. The overlap on the long side should be 100mm and the short side should be 150mm.

3. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

Package

the membrane is launched into the market in rolls 1m wide and 10m long.

Storage Conditions and Service life

Rolls must be vertically stored in roofed-over spaces. If the rolls have to be stored outdoors for a long period of time, then they must be covered with a protective layer in order to protect them against the sunlight. If the rolls are to be stowed without pallets, they they are not stacked one on top of another. In palletised stowage, two rows may be stacked one on top of the other.

Attentions for Construction

·

SBS / APP asphalt waterproof membrane, bituminous waterproof membrane

1. Membranes should be stored under dry and ventilated conditions.

2. Different types of membranes must be piled separately.

3. Under usual condition, storage period is one year since production date.

4. Membrane roll should be put vertically during transportation. It should be kept away

from sunshine and rainwater.

Installation Sketch point

Clean the substrate using broom or high pressure dusty cleaner.

Apply primer

Heat the membrane bottom using a high temperature flame gun.

Push forward while the primer and membrane oil melted

Use a roller to push hard the membrane surface to ensure it stick firmly

- Q:Can waterproofing membranes be used on elevator pits?

- Indeed, elevator pits can benefit from the utilization of waterproofing membranes. Given their underground location, elevator pits are susceptible to water infiltration, which can lead to detrimental water damage and leaks. To combat these moisture-related issues, waterproofing membranes offer a highly effective solution by preventing water penetration and safeguarding elevator pits. Typically composed of rubber, polyurethane, or bitumen, these membranes are specifically designed to create a watertight barrier. Through their application on the walls and floor of the elevator pit, they form a seamless and durable protective layer. As a result, this membrane system ensures the maintenance of a dry pit, consequently preventing water damage to the elevator components and ensuring the safe and reliable operation of the elevator.

- Q:Can a waterproofing membrane prevent mold and mildew growth?

- A waterproofing membrane has the ability to prevent the growth of mold and mildew. Mold and mildew thrive in areas that are damp and moist, but waterproofing membranes act as a barrier that stops water from seeping into the surfaces below. By ensuring that the area remains dry, the membrane reduces the conditions needed for mold and mildew to grow. Furthermore, certain waterproofing membranes are specifically designed to have antimicrobial properties, which further hinder the growth of mold and mildew. However, it is important to remember that while a waterproofing membrane can help prevent mold and mildew growth, it is not a guaranteed solution. Proper ventilation and maintenance are also essential in preventing these problems.

- Q:Can a waterproofing membrane be applied on top of roofing materials?

- Yes, a waterproofing membrane can be applied on top of roofing materials. It is common practice to install a waterproofing membrane on top of roofing materials to provide an additional layer of protection against water infiltration and extend the lifespan of the roof.

- Q:Can a waterproofing membrane be used for above-grade applications?

- Yes, a waterproofing membrane can be used for above-grade applications. Waterproofing membranes are designed to provide a barrier against water infiltration and can be applied to exterior walls, roofs, and other above-grade structures to prevent water damage.

- Q:Can waterproofing membranes be used on shower walls?

- Yes, waterproofing membranes can be used on shower walls. These membranes are specifically designed to create a barrier against water, preventing leaks and protecting the underlying structure from moisture damage. Applying waterproofing membranes on shower walls is a common practice to ensure a watertight and durable shower enclosure.

- Q:Is a waterproofing membrane compatible with different types of flooring materials?

- Different types of flooring materials can be used with a waterproofing membrane. The purpose of a waterproofing membrane is to create a barrier between the subfloor and the flooring material, preventing moisture from causing any damage. This means that it can be used with laminate, vinyl, tile, and even hardwood flooring. By using a waterproofing membrane, the flooring material will remain protected from water damage, allowing it to last longer and maintain its appearance. However, it is important to keep in mind that specific compatibility requirements may exist for different types of waterproofing membranes. Therefore, it is advisable to consult the manufacturer's guidelines to ensure the proper installation of the chosen flooring material.

- Q:Can a waterproofing membrane be used for a stadium?

- Yes, a waterproofing membrane can be used for a stadium. Waterproofing membranes are commonly used in construction projects to prevent water infiltration and protect structures from moisture damage. In the case of a stadium, a waterproofing membrane can be applied to the building's foundation, roof, or any other areas that are susceptible to water penetration. This will help ensure the longevity and structural integrity of the stadium by preventing water-related issues such as leaks, mold, and deterioration.

- Q:What is the lifespan of a waterproofing membrane in extreme weather conditions?

- The lifespan of a waterproofing membrane in extreme weather conditions can differ depending on various factors. These factors include the quality of the membrane, the intensity and duration of the weather conditions, and the maintenance and care given to the membrane. Typically, waterproofing membranes designed for extreme weather conditions can last 20-30 years or more if they are of high quality. These membranes are usually made from durable materials like modified bitumen, PVC, EPDM, or TPO. These materials are specifically engineered to endure harsh weather elements. It is worth noting that extreme weather conditions, such as heavy rain, intense sunlight, freezing temperatures, or strong winds, can speed up the deterioration of the membrane. For instance, prolonged exposure to UV radiation can cause the membrane to degrade and lose its effectiveness over time. To extend the lifespan of the waterproofing membrane in extreme weather conditions, regular maintenance and inspections are crucial. By promptly addressing any signs of damage, such as cracks, tears, or leaks, and conducting regular cleaning and resealing, the membrane can be better shielded against the harsh effects of extreme weather. Moreover, proper installation techniques and adherence to the manufacturer's guidelines are vital for ensuring the longevity of the waterproofing membrane. Hiring experienced professionals who are familiar with installing membranes in extreme weather conditions can significantly contribute to the durability and lifespan of the membrane. Ultimately, while a high-quality waterproofing membrane can endure extreme weather conditions for several decades, it is important to regularly monitor its condition, provide proper care and maintenance, and promptly address any issues that arise in order to maximize its lifespan.

- Q:Can a waterproofing membrane be applied on curved surfaces?

- Yes, a waterproofing membrane can be applied on curved surfaces. In fact, waterproofing membranes are designed to be flexible and adaptable, making them suitable for application on various shapes and contours, including curved surfaces. These membranes are typically made from materials such as modified bitumen, polyurethane, or rubber, which have excellent elongation and flexibility properties. They can be easily molded and stretched to conform to curved surfaces without compromising their waterproofing capabilities. This allows for effective waterproofing of structures with curved components like roofs, balconies, tunnels, and tanks. Proper installation techniques and specialized tools may be required to ensure proper adherence and complete coverage on curved surfaces, but with the right expertise and materials, waterproofing membranes can be successfully applied on curved surfaces.

- Q:Are waterproofing membranes resistant to rodent and insect infestation?

- Waterproofing membranes are generally not specifically designed to be resistant to rodent and insect infestation. While they may provide a barrier against water and moisture, they may not necessarily prevent rodents and insects from accessing or damaging the membrane. It is advisable to take additional measures, such as using pest control methods or installing barriers, to effectively address rodent and insect infestation issues.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SBS Elastomeric Polymer Bitumen Waterproof Roofing Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords