Sanding Screen Discs High Strength 400C A Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Sanding Screen Discs Description:

Sanding Screen Discs is made of nylon fabric, coated with abrasive materials; there are three kinds of shape: Sheets, Discs and Rolls.It is not only suitable for sanding plaster and wall surface, but also for sanding rusty spots of metal materials and making grinding and polishing treatment. It has good properties of grinding, cutting and filings removing. And it is the most ideal abrasive tool for interior decoration.

2.Main Features of Sanding Screen Discs:

High grinding efficiency, fine functioning in chip removal, excellent water tolerance and long service life

Has excellent performances of grinding, cutting and filings removing.

Being coated with abrasive materials on each side, both sides of the screens can be used

Sanding Surface of woodworking, plaster metal, plastic, enamel and remove rusty and making grinding and polishing treatment.

Easily cleaned by water, dried by air for reuse

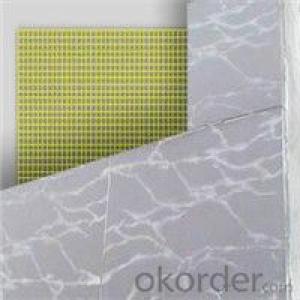

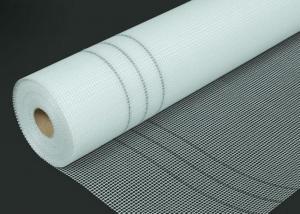

3. Sanding Screen Discs Images

4. Sanding Screen Discs Specification

Grain | Grit | Feature | Application |

A | P16~P320 | special aluminium oxide.closed coat,quality fiber(T=0.8mm,T=0.6mm),High tensile,high wearing resistant | hard wood,furniture,wood and general metal |

ZA | P16~P120 | Closed coated, quality fiber(T=0.8mm),High tensile,high wearing resistant | general metal,stainless steel,weld seam,hard wood etc |

SIC | P16~P320 | Close coat,Chinese fiber(T=0.8mm),high tensile strength,high wearing resistance,high grindingh efficiency | non-ferrous metal,marble,glass,ceramic and other non-metal material,stone etc |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Self making method and formula of glass fiber mesh cloth shaping glue

- The external wall insulation mesh (glass fiber mesh) with alkali or alkali glass fiber yarn, woven glass fiber mesh to the substrate, and then a new alkali resistant products coated with acrylic copolymer solution after drying into. The product has the advantages of stable structure, high strength, good alkali resistance, corrosion resistance, crack resistance, etc., and the enhancement effect is the best, and the construction is simple and easy to do. Mainly used for cement, gypsum, wall, building and other structures to enhance the internal and external surface, crack prevention, is a new type of building materials insulation project.

- Q:What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- The difference lies in the degree of use of alkali resistant glass fiber, at present there are very few domestic high alkali glass fiber products, the difference is in the base. Because the glass itself is not alkali resistant, so in the processing of glass fiber products add alkali resistant components, adding two zirconia, the glass fiber has certain effect on tolerance -OH.The mesh fabric produced with alkali resistant glass fiber is alkali resistant grid cloth, and the others are the same

- Q:Do external insulation with alkali resistant fiberglass mesh cloth, why should the first layer be double or thickened?

- Because the first floor of human activities may be exposed to the outer wall, easy to destroy the exterior insulation system

- Q:How is fiberglass mesh used?

- The wall should be cleaned before paving and the pits will be patched and leveled

- Q:How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

- Q:What's the price of fiberglass mesh?

- The elastic coefficient is high, the elongation within the elastic limit is related to the tensile strength of the alkali resistant fiberglass mesh cloth

- Q:Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- To increase the penetration of some surface active agent, increase the permeability of the emulsion, adding some phenolic thermosetting resin, melamine formaldehyde and improve sizing effect, to prevent the resurgence of soft, adding cationic film plasticized thermosetting resin while reducing fiber absorption and softening fiber

- Q:What are the transverse and longitudinal tensile forces of alkali resistant glass fiber mesh cloth?

- No, it should be a large longitudinal tension

- Q:The building is how to choose the external wall thermal insulation material of glass fiber mesh cloth?

- Glass fiber mesh cloth is often used with the external wall insulation system, will not have a "cold bridge and bridge", has praised the outstanding architectural energy-saving effect, which has been in the construction industry.

- Q:Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- This is absolutely no problem. Is the insurance, you, than it is to use some wall tiling grid cloth, ordinary mortar mortar is much better, but the cracking phenomenon is not so much that they...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sanding Screen Discs High Strength 400C A Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords