PTFE Cooking Liner

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000m2 m²

- Supply Capability:

- 500000M2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

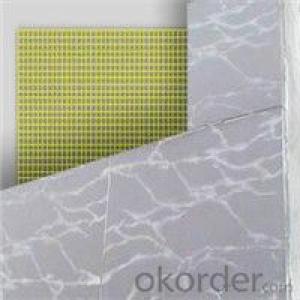

Description of PTFE Cooking Liner:

Our cooking liner comes from PTFE coated glass fabrics, which take full advantage of its non-stick surface and high temperature resistance characteristics. After cooking, when you put the liner back to the oven, it may never need clean again. For fat free cooking: Reduce the amount of the oil in cooking, take the roll of cooking liner and the pan, cut a circle that will fit the base of the need for added oil and without compromising flavor. The size can be cut according to the machine.

Properties:

●Cut to fit for any size use – template included

●Get the same results as professional bakers

● Made from a patented nonstick surface

●Bakes food more evenly

●Reusable on either side

●No greasing or cooking sprays needed (great for low-cal cooking)

●Safely transfer from freezer to oven or microwave

●Dishwasher safe for simple clean-up

Applications of PTFE Cooking Liner:

● Used for food pyrogenation

1) use the scissors to cut the grill to the requested size and shape;

2) put on the boiler, tray or other container;

3) put the food on the grill;

4) after the good baking deeply, waiting it refrigeration and getting it out, washing it with water;

5) the grill could be used time and again

●Used as cushion of oven.

1) Electronic oven---put on the button or nethermost grill of the electronic oven;

2) Steam oven---put on the nethermost grill but not the button of the oven;

Specification PTFE Cooking Liner:

● 9008-I, 0.08mm brown or black grill;

● 9013-I, 0.13mm brown or black grill;

●9008BS-I, 0.08mm, advanced black-grey grill;

●9013BS-I, 0.13mm, advanced black-grey grill;

●mesh grill, such as 1*1mm mesh size, 2*2mm, 4*4mm, 10*10, etc.

- Q:The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- Grid cloth stereotypes are used in the market, a wide range of species, can generally be divided into urine gel, latex twoThe grid cloth made of urine gum is hard, and the quality of latex is almost worse than that of latex

- Q:What are the fiberglass mesh fabric manufacturers?

- Offiberglass self-adhesive caulkingGlass fiber self-adhesive tapes are made from high quality glass fiber fabric coated with acrylic copolymer, which is stable and difficult to oxygen because of its chemical propertiesSo, we developed production offiberglass self-adhesive caulking is not only superior to other similar products There is nothing comparable to this.

- Q:Can fiberglass mesh waste be recycled? What can you do if you can?

- Mesh cloth, such as discarded cloth, is not corrosive and may not corrode for hundreds of years, causing serious pollution to the land;

- Q:What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- How to identify quality problems of alkali resistant glass fiber cloth, glass fiber cloth market price of 1. of the worst is usually around 1 yuan -1.60 yuan, his glass fiber is usually made of some kind of waste glass beer bottles, the production process for clay crucible drawing, production process is prohibited by the state, the surface coating is non alkali resistant emulsion. From the intuitive point of view: the work is relatively rough, generally sold in the market volume of the theory, often lack of length, grams of weight is not enough, two fold on the break, the contact is not firm, easy to shift, and easy to stab the skin. In the insulation layer in general in the two months after the loss of strength using the grid cloth, if the mortar off grid cloth out, just gently crushed, fiberglass yarn is made into powder.

- Q:Self making method and formula of glass fiber mesh cloth shaping glue

- Glass fiber mesh cloth with alkali resistant fiberglass mesh, it uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by structure leno weaving and special organization, after the anti alkali, heat setting treatment such as reinforcing agent.

- Q:Do external insulation with alkali resistant fiberglass mesh cloth, why should the first layer be double or thickened?

- Because the first floor of human activities may be exposed to the outer wall, easy to destroy the exterior insulation system

- Q:How is fiberglass mesh used?

- Brushing the wall latex Putie mesh cloth, mesh cloth to Putie formation, Jiecha overlap should be at least 50MM, to be completely dry after the wall, and then carry out the procedure.

- Q:Slotted walls, seams, seams, tape, or anti mesh cloth?

- Very simple, you do not have to spend so much money to buy what tape and mesh cloth, is decorated well, to buy the cheapest dacron, remember to not want that kind of chemical fiber, cotton, cotton for a long time to decay. Because in the fiber wall sealed with aging, so. Then through the plaster smooth dry, tore the cloth into strips, glue brush in the gap, and then dried, powder, and you will not crack, affordable, the effect is very good, we give people a lot of friends after use, not see who split over ten years.

- Q:Where is fiberglass mesh better?

- Quality and import gap is not large, but prices are significantly lower. If you do not take the price into consideration, it must be the best of the imports.

- Q:Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- To increase the penetration of some surface active agent, increase the permeability of the emulsion, adding some phenolic thermosetting resin, melamine formaldehyde and improve sizing effect, to prevent the resurgence of soft, adding cationic film plasticized thermosetting resin while reducing fiber absorption and softening fiber

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China |

| Year Established | 2005 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America Eastern Europe Southeast Asia Mid East Eastern Asia Western Europe |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | High and/or Average |

Send your message to us

PTFE Cooking Liner

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000m2 m²

- Supply Capability:

- 500000M2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords