PTFE Fusing Machine Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000m2 m²

- Supply Capability:

- 500000M2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PTFE Fusing machine Belt:

1.PTFE seamless fusing machine belt:

The belt is made of high tensile fiberglass or Kevlar, knitted by special equipment and coated with fine PTFE. Seamless belt overcomes former problems of traditional joint fusing machine belt such as bad stability, ruptures, and deflecting for different girth on two sides at the joint. The using life of seamless PTFE Fusing Machine Belt are much longer than all kinds of joint PTFE Fusing Machine Belt.

2. Common seam fusing machine belt:

Seam fusing machine belt is made of fine material. The surface is smooth and luster and the price is competitive. It can substitute imported high price belts.

3. 2ply fusing machine belt:

with static-resistance varnished cloth inside and tearing-resistance fiberglass cloth outside, 2ply belt has a great improvement on its intensity, long using life, well balanced thickness, excellent deflecting preventing capacity, smooth surface, it’s better for super thin fabric fusing.

- Q:The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- Grid cloth stereotypes are used in the market, a wide range of species, can generally be divided into urine gel, latex twoThe grid cloth made of urine gum is hard, and the quality of latex is almost worse than that of latex

- Q:What are the fiberglass mesh fabric manufacturers?

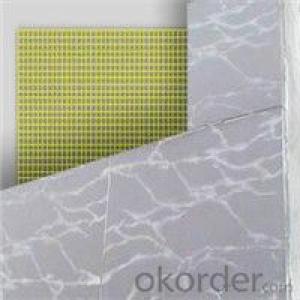

- Mesh cloth (heat preservation net)The mesh cloth is based on medium alkali or E-glass fiber woven fabric and is treated with alkali resistant coating. The product has high strength and good alkali resistance, and plays an important structural role in the thermal insulation system, mainly to prevent cracks. Due to its excellent acid, alkali and other chemical substances pedants performance and weft tensile strength is high, can make the wall stress of dispersed insulation system, can avoid the extrusion deformation, external force caused by the collision of the insulation structure, the insulation layer has high impact resistance strength, and easy to construction and quality control, to "soft steel" role in the insulation system.

- Q:What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- How to identify quality problems of alkali resistant glass fiber cloth, glass fiber cloth market price of 1. of the worst is usually around 1 yuan -1.60 yuan, his glass fiber is usually made of some kind of waste glass beer bottles, the production process for clay crucible drawing, production process is prohibited by the state, the surface coating is non alkali resistant emulsion. From the intuitive point of view: the work is relatively rough, generally sold in the market volume of the theory, often lack of length, grams of weight is not enough, two fold on the break, the contact is not firm, easy to shift, and easy to stab the skin. In the insulation layer in general in the two months after the loss of strength using the grid cloth, if the mortar off grid cloth out, just gently crushed, fiberglass yarn is made into powder.

- Q:Method for sampling alkali proof glass fiber mesh cloth

- The polymer mortar ratio is: KL binder: 425# sulphoaluminate cement: sand (with 18 mesh screen bottom),:=1:1.88:3.25 (weight ratio).

- Q:What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- Alkali resistant two zirconium oxide content is large, mesh cloth prices high, good quality, high alkali is generally made of glass pulled wire mesh cloth, the state explicitly eliminated things, low prices, poor quality. Medium alkali glass fiber yarn coated with alkali resistant glue is also alkali resistant, quality can moderate price.

- Q:Glass fiber mesh cloth bent do to straighten it?

- Can be divided into gold pot and earthen pot, the general earthen pot product soft and hard to control, because the surface of the pot products are generally coated with urine glue, gold pan surface coated with emulsion, quality is good, control some. Soil pot products only two kinds of hard and soft state, one is hard, then the product is slightly, but the texture is brittle, the tensile resistance is not good, it is easy to break ninety percent off, a state is soft, this product is pulling resistance is large, but not so on the location, soil pot coated urine glue products, soft and positioning the product is contradictory, hard, good positioning effect, small tensile strength, soft, poor positioning effect, large force.

- Q:Self-adhesive fiberglass mesh

- EPS mesh made of alkali resistant glass fiber fabric, it uses alkali free glass fiber yarn by weaving leno weave structure and special organization, after the anti alkali, heat setting treatment such as reinforcing agent, finally by not dry glue coating baked. A EPS mesh fabric with alkali resistance, softness, adhesion and tensile resistance is formed.

- Q:What's the use of fiberglass mesh?

- Main performance and characteristics:1 、 good chemical stability. Alkali resistance, acid resistance, water resistance, cement corrosion resistance, and resistance to other chemical corrosion; and resin adhesion, soluble in styrene and so on.2, high strength, high modulus, light weight.3, good dimensional stability, stiffness and smooth, not easy to deformation, shrinkage of.4 、 good shock resistance. (because of high mesh strength and good toughness)5, mildew change, pest control.6. Fire protection, heat preservation, sound insulation and insulation.

- Q:What harm does fiberglass mesh have to people?

- Into the digestive system, may cause digestive diseases.

- Q:Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- Now, many sites are pure in the transfer problem of various types of work, if the base treatment bends up, after the winter freeze will soon fall, you can put the case to the party to write a material, as long as you don't sign the party a no problem.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China |

| Year Established | 2005 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America Eastern Europe Southeast Asia Mid East Eastern Asia Western Europe |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | High and/or Average |

Send your message to us

PTFE Fusing Machine Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000m2 m²

- Supply Capability:

- 500000M2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords