Safe Durable Cuplock System for Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Safe Durable Cuplock System for Construction

Type: Heavy Section Steel

Forming: Welding Products

Standard:

Member:

Trademark:

Connection Form:

Carbon Structural Steel:

Residential Wall Structure:

Type of Steel For Building Structure:

Bs1139, En74 Standard:

Export Markets:

Descriptions of Safe Durable Cuplock System for Construction

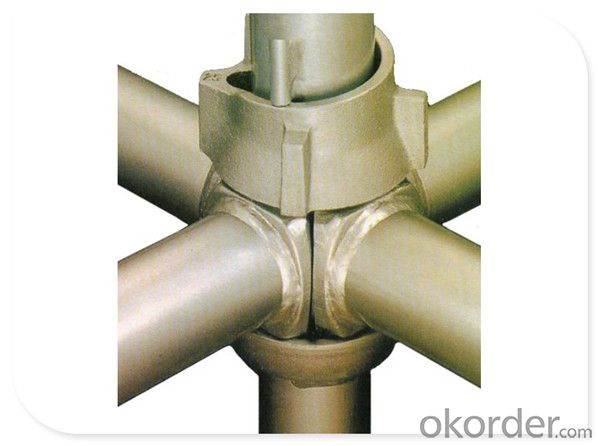

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Safe Durable Cuplock System for Construction

Multi-functional-with the universal joint and fully interchangeable components, the cuplock system can be used in most construction projects for both formwork and access. It is very versatile and diverse. Use in the shipping industries, oil and gas and aviation industries.

Versatile-Verticals are assembled with horizontals and diagonals using secure fixed cup connections. Its versatility has a distinct advantage to conventional scaffolding methods. A positive & ridged connection of four units is achieved in one single action. The cupock system is very cost effective and can be erected safely and quickly.

Time saving-cuplock scaffold is the solution for temporary structures Performance stages. Small teams can erect it safely and quickly.

Economical-Easily assembled system scaffold saves time and labor costs.

Durable-All components are hot dip galvanized and manufactures to international standard.

Easily Stored-Individual pipe elements can be packed in bundles for easy storage and transportation. For returns, material can be packed in steel racks.

The Main Components of Safe Durable Cuplock System for Construction

Verticals

Description

Material

kg/pc

Article No.

9'10" Vertical 3.00m

Q345 φ48.3×3.2

16.90

SC1001 3000

8'2" Vertical 2.50m

Q345 φ48.3×3.2

14.20

SC1001 2500

6'6" Vertical 2.00m

Q345 φ48.3×3.2

11.60

SC1001 2000

4'11" Vertical 1.50m

Q345 φ48.3×3.2

8.90

SC1001 1500

3'3" Vertical 1.00m

Q345 φ48.3×3.2

6.20

SC1001 1000

1' Vertical 0.50m

Q345 φ48.3×3.2

3.50

SC1001 0500

Horizontals

Description

Material

kg/pc

Article No.

10'0" Horizontal 3.05m

Q345 φ48.3×3.2

11.80

SC1002 3048

9'0" Horizontal 2.74m

Q345 φ48.3×3.2

10.70

SC1002 2743

8'2" Horizontal 2.50m

Q345 φ48.3×3.2

9.80

SC1002 2500

7'0" Horizontal 2.13m

Q345 φ48.3×3.2

8.40

SC1002 2133

6'6" Horizontal 2.00m

Q345 φ48.3×3.2

7.90

SC1002 2000

6'0" Horizontal 1.83m

Q345 φ48.3×3.2

7.20

SC1002 1828

5'11" Horizontal 1.80m

Q345 φ48.3×3.2

7.10

SC1002 1800

5'0" Horizontal 1.52m

Q345 φ48.3×3.2

6.10

SC1002 1524

4'11" Horizontal 1.50m

Q345 φ48.3×3.2

6.00

SC1002 1500

4'1" Horizontal 1.25m

Q345 φ48.3×3.2

5.00

SC1002 1250

4'0" Horizontal 1.22m

Q345 φ48.3×3.2

4.90

SC1002 1219

3'6" Horizontal 1.07m

Q345 φ48.3×3.2

4.30

SC1002 1067

3'3" Horizontal 1.00m

Q345 φ48.3×3.2

4.10

SC1002 1000

3'0" Horizontal 0.91m

Q345 φ48.3×3.2

3.80

SC1002 0914

2'11" Horizontal 0.90m

Q345 φ48.3×3.2

3.70

SC1002 0900

8'0" Horizontal 2.44m

Q345 φ48.3×3.2

9.50

SC1002 2438

1'10" Horizontal 0.57m

Q345 φ48.3×3.2

2.40

SC1002 0600

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Who knows how much the amount of the main material used to take one square metre of conventional double row scaffolding (within 12 meters). For example, how many kilograms of steel pipe, the number of fasteners. The content of the quota is low, I am also very confused, to the completion of the work of the scaffolding rental fees. Very urgent, I hope to know the user to answer. Accident report

- (less than 12 meters), such as how many kilograms of steel pipe, the number of fasteners

- Q:I am currently taking early childhood care education as my college major. I am learning about ZPD (Zone of Proximal Development), and scaffolding the the development in early childhood.How would you explain, and define scaffolding

- Maybe this will help: scaffolding is the support provided by adults working with a child to help promote and extend development of knowledge and skills. It can mean asking appropriate questions to help extend a child's thought process, or providing suitable activities to help a child learn through hands-on activities. Look it up in your textbook and read the definition and apply it to my explanation above for a deeper understanding, and don't be afraid to ask your instructor questions like this! That's what s/he is there for!

- Q:Please help me in building professional people (scaffolding)

- Please know a good personLearn slowlyWell then consider whether or not to kick offMore types of scaffolding

- Q:Okay so I want to get either done, I just want to know which one is more painful. Not felling that nervous because I have had my nose and tongue done. I want to know which one is more painful and how to clean each of them. And also with the lip, is it more like the tongue with what foods you can eat and how hard it is to eat?

- Everyone is different as far as what piercings they think hurt more or less, but based on my own experience, I'd say the scaffolding hurt more by far. Now, I've never had my lower lip pierced, but I had my upper lip area (I used to have angel bites), so I'd image it would have to be similar to the lower lip as far as pain, care, healing. As far as cleaning them, it's like most other piercings, where the best thing for you to use is warm sea salt water. But although everyone's different, the lip is going to be the faster healing of the two I'd say for basically anyone. The scaffolding takes up to a year to fully heal. The lip heals relatively fast;usually anything involving your mouth area heals quicker than other areas of the body-I'm sure you noticed how your tongue healed fast. Or even if you accidentally bite or cut anything involving your mouth, tongue, inside of your cheeks, etc., it heals faster than other areas. As far as the foods other aftercare with it, it is somewhat similar to your tongue in caring for it-just follow your piercer's instructions you'll be fine. Good luck!

- Q:How long is the service life of disc scaffolding?

- Will bring to the construction of a series of security risks, Hunan Billiton Industrial Group Co., Ltd. to provide information is generally 3-5 years

- Q:I know people have different pain thresholds. But I was wondering if it was more painful than a lobe piercing? It will be done with a needle and are they aloud to freeze it? Or is it not needed?

- I got my lobes pierced 5 years before my industrial so I can't compare the pain but everyone says industrial. Idk if they can freeze or not. The pain is completely tolerable.

- Q:From the Scarlet Letter, Ch. 10-12

- Haven't read this book in years but I believe he goes back to the scaffold at night because he is being eaten away by guilt. It is a type of redemptive action, just as Hester had to stand there and be judged for her sins he feels the need to also stand there on the scaffold with Hester (theoretically) and be judged/punished as well, the only difference, of course, is that he does it under the cloak of night, when no one can see him.

- Q:Topic?Scaffolding construction program how to doSpecial construction scheme

- Full support calculation method:1, determine the above line load (ie, the length of a variety of meters, take the maximum);2, to determine the bearing capacity of the foundation (through the strengthening of the bearing capacity);3, according to the bearing capacity of the foundation, about how many square meters per square meter to determine the vertical tube, assigned to specific point load;4, to determine the number of tons of vertical pipe can be per ton (according to pipe diameter, wall thickness calculation of allowable stress);

- Q:Bracket cast-in-place beam bracket must use bowl buckle scaffold, can not use fastener type scaffolding, there is no mandatory requirements, or specification file requirements!

- No mandatory provisions.JGJ1622008 construction formwork safety technical specifications, is the latest specification

- Q:also apprx. what chapters is it in?

- On the Scaffold Dimmesdale is really starting to go crazy. the guilt in his heart about loving hester is eating him up. he goes onto the scaffold thinking no one will see him. he is punishing himself. he yells out and thinks that it will be the end of his secrect but no one hears him. they just think he is the cry in the night. then reverend wilson comes along. but he doesnt see dimmesdale. then hester and pearl walk by they notice them. they come up on the scaffold. Pearl asked dimmesdale if he would stand with hester and her at noon the next day but of he says no that he will only stand with them on Judgement Day. then they see the scarlet letter in the sky and the town people thought that it was just an a for angel because the gov passed away. they next day wilson finds dimmesdale's glove on the scarrold but he thought that the devil put it there. i cant remember what chapter it is in but it is toward the middle good luck with the book i loved it

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Safe Durable Cuplock System for Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords