SAE 1035 Carbon Steel Round Bar CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

SAE 1035 Carbon Steel Round Bar

Product Description:

1. Sizes: Diameter: 16mm-300mm; Length: 6m, 9m, 12m

2. Grade: 35#, SAE1035, S35C, C35

3. Invoicing on theoretical weight or actual weight as customer’s request

4. Shape: Round bar, solid bar of steel with circular section

5. Technique: Hot rolled, forged, cold rolled

Chemical Composition:

| C | Si | Mn | P | S | Ni | Cr | Cu |

| 0.32-0.40 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.25 | ≤0.25 |

Packing and Delivery:

Packing in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: Approx.45 days

Usage and Applications

1. Steel round bar is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some especial material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Specification:

OD | Length | Material | Standard | Technique |

16-260mm | 6-12m or aques per request | 20# | GB ASTM DIN | Hot rolled |

16-350mm | 35# | |||

200-500mm | 35# | Forged | ||

20-250mm | 20Cr,40Cr,20-42CrMo | Hot rolled | ||

50-300mm | GCr15 |

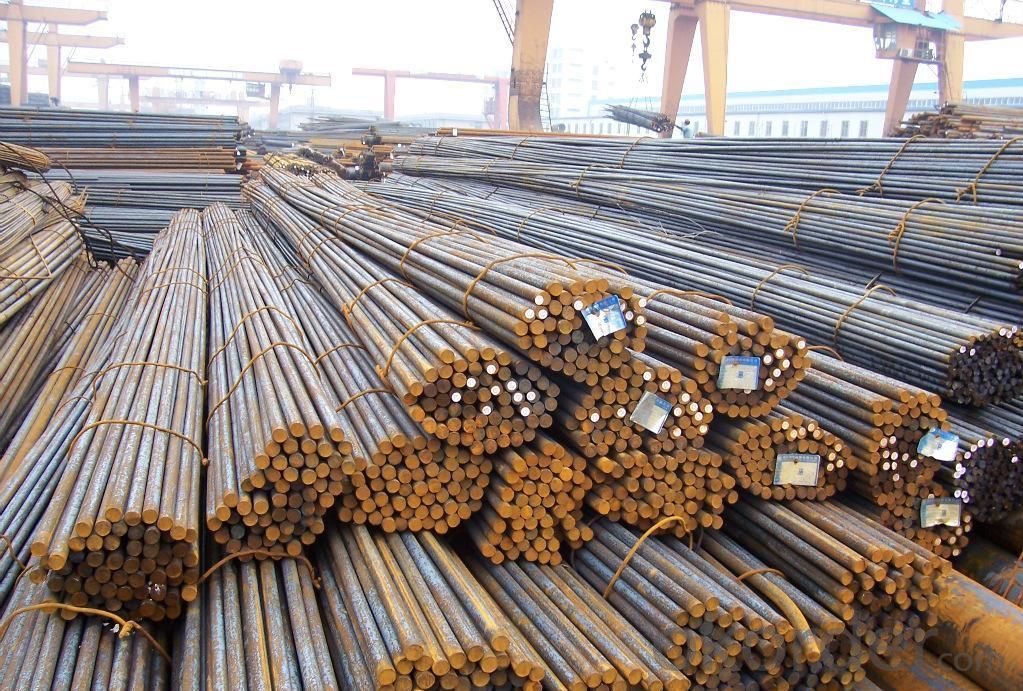

Main product pictures:

- Q:What are the different methods for improving the fatigue strength of special steel?

- There are several methods for improving the fatigue strength of special steel. 1. Heat treatment: One of the most common methods is through heat treatment processes such as annealing, quenching, and tempering. These processes help to refine the microstructure of the steel, reducing the presence of impurities, and improving its fatigue resistance. 2. Surface treatment: Surface treatments like shot peening and nitriding can enhance the fatigue strength of special steel. Shot peening involves bombarding the surface of the steel with tiny metal particles, inducing compression stress in the material, which helps to prevent crack initiation and propagation. Nitriding involves diffusing nitrogen into the surface layer of the steel, forming a hard and wear-resistant nitride layer that enhances the fatigue resistance. 3. Alloying: Alloying special steel with certain elements can significantly improve its fatigue strength. For example, adding chromium, molybdenum, or vanadium can enhance the steel's hardenability and resistance to fatigue. These alloying elements form carbides or nitrides, which act as barriers to crack propagation. 4. Surface coatings: Applying protective coatings like electroplating, hot-dip galvanizing, or physical vapor deposition (PVD) can help improve the fatigue strength. These coatings provide a barrier against environmental factors that may lead to corrosion or surface damage, ultimately enhancing the fatigue life of the steel. 5. Grain refinement: By refining the grain size of the steel through processes like severe plastic deformation or equal channel angular pressing (ECAP), the fatigue strength can be improved. Fine-grained steels have a higher resistance to crack initiation and propagation, resulting in enhanced fatigue properties. 6. Residual stress management: Controlling and managing residual stresses in the steel can improve its fatigue strength. Techniques like stress relieving or shot peening can help to reduce tensile residual stresses, which are detrimental to fatigue resistance. It is important to note that the selection of the most appropriate method for improving fatigue strength depends on the specific requirements, the type of special steel, and the intended application of the material.

- Q:Can special steel be used in the textile industry?

- Yes, special steel can be used in the textile industry. Special steel alloys, such as stainless steel, can be used for textile machinery components like needles, pins, and various parts of looms. These steel alloys provide excellent strength, corrosion resistance, and durability, making them suitable for demanding textile manufacturing processes.

- Q:What are the different forms of special steel available in the market?

- There are several different forms of special steel available in the market, each with its own unique properties and applications. Some of the most common forms include: 1. Stainless Steel: This is a versatile form of special steel that is highly resistant to corrosion and staining. It is commonly used in the production of cutlery, kitchen appliances, and medical equipment. 2. Tool Steel: This type of special steel is highly durable and resistant to wear and tear. It is primarily used in the manufacturing of cutting tools, molds, and dies. 3. High-speed Steel: As the name suggests, high-speed steel is designed to withstand high temperatures and retain its hardness even at elevated speeds. It is commonly used in the production of drill bits, saw blades, and gear cutters. 4. Alloy Steel: This form of special steel is created by adding various alloying elements such as chromium, nickel, or molybdenum to improve its strength and durability. Alloy steel is widely used in the automotive industry, construction, and machinery manufacturing. 5. Carbon Steel: Carbon steel is a popular form of special steel due to its affordability and high strength-to-weight ratio. It is commonly used in the construction of buildings, bridges, and pipelines. 6. Maraging Steel: Maraging steel is a type of low-carbon, high-nickel steel that is known for its exceptional strength and toughness. It is often used in aerospace and defense applications, such as aircraft components and missile casings. 7. Spring Steel: This form of special steel is specifically designed to withstand high stress and maintain its shape under repeated heavy loads. It is commonly used in the production of springs, such as those found in automotive suspensions and mechanical devices. These are just a few examples of the different forms of special steel available in the market. Each type has its own unique set of properties and applications, making them suitable for a wide range of industries and manufacturing processes.

- Q:Can special steel be used in the medical field?

- Yes, special steel can be used in the medical field. Special steel alloys such as stainless steel are commonly used in medical devices and surgical instruments due to their excellent corrosion resistance, durability, and biocompatibility. These properties make special steel ideal for applications requiring cleanliness, strength, and resistance to body fluids.

- Q:What are the different classifications of special steel?

- Various types of steel alloys fall under the category of special steel, each possessing unique properties and characteristics that make them suitable for specific applications. Special steel can be classified into several categories: 1. Stainless Steel: This special steel contains a high percentage of chromium, which provides excellent corrosion resistance. It also typically includes elements like nickel and molybdenum, enhancing its strength and durability. Stainless steel finds common use in applications requiring resistance to oxidation, heat, chemicals, and wear, such as in food processing, medical devices, and construction. 2. Tool Steel: Specifically designed for manufacturing tools, dies, and molds, tool steel is known for its exceptional hardness, wear resistance, and toughness. Tool steel is further categorized into subcategories like high-speed steel (HSS), cold work steel, hot work steel, and plastic mold steel, each tailored for specific tooling applications. 3. Alloy Steel: This type of special steel contains additional alloying elements besides carbon. These elements, like manganese, silicon, nickel, chromium, and molybdenum, are added to enhance specific properties such as strength, toughness, hardenability, and corrosion resistance. Alloy steels are used in various applications, including automotive components, machinery, construction, and aerospace. 4. Spring Steel: Specifically designed to withstand repeated bending or twisting without permanent deformation, spring steel possesses excellent elasticity and fatigue resistance. It finds applications in springs, suspension systems, and high-performance automotive parts. 5. Bearing Steel: Bearing steel is engineered to provide high hardness, wear resistance, and dimensional stability necessary for manufacturing bearings. It typically contains high levels of carbon, chromium, and other alloying elements, ensuring the required mechanical properties for reliable and long-lasting bearings. 6. Electrical Steel: Also known as silicon steel, electrical steel is specifically designed for electrical applications. It possesses low electrical resistivity and high magnetic permeability, allowing efficient conduction and transformation of electrical energy. Electrical steel is commonly used in transformers, electric motors, and generators. These classifications of special steel emphasize the versatility and tailored properties of different steel alloys, enabling their application in a wide range of industries and specialized uses.

- Q:What are the different methods of surface shot blasting for special steel?

- Special steel can be subjected to various surface shot blasting techniques. Among the most commonly employed methods are: 1. Wheel blasting: Utilizing a rapidly spinning wheel embedded with abrasive particles, this technique eliminates impurities and imperfections from the surface of the special steel. 2. Air blasting: By propelling abrasive particles onto the special steel surface using compressed air, this method achieves a thorough cleaning and prepares the surface for subsequent treatment or coating. 3. Wet blasting: This approach involves blending abrasive particles with water and spraying the resulting mixture onto the special steel surface. The inclusion of water helps manage dust and heat generated during the blasting process, rendering it suitable for delicate or sensitive steel surfaces. 4. Vacuum blasting: By incorporating a vacuum system alongside abrasive particles, this technique effectively eliminates both particles and contaminants from the special steel surface. It proves particularly valuable for removing paint or coatings. 5. Shot peening: Employed as a specialized variant of shot blasting, shot peening enhances the strength and fatigue resistance of special steel. It entails bombarding the surface with small spherical particles, generating compressive stresses that bolster the steel's durability. Each of these methods offers distinct advantages and is suitable for different types of special steel and surface conditions. The selection of the appropriate technique hinges upon factors like desired surface finish, contamination levels, and specific steel application requirements.

- Q:Can special steel be used for cutting tools?

- Yes, special steel can be used for cutting tools. Special steel alloys, such as high-speed steel (HSS) or tool steel, are specifically designed to have enhanced hardness, toughness, and wear resistance, making them ideal for cutting applications. These steel types can maintain their sharpness and withstand high temperatures and forces, ensuring efficient and durable cutting performance.

- Q:What are the requirements for special steel used in wind turbines?

- The reliability, efficiency, and durability of large-scale renewable energy systems, such as wind turbines, rely heavily on the crucial requirements for special steel. Here are some key considerations: 1. Strength and Durability: To withstand the harsh operating conditions, including strong winds, vibrations, and extreme temperature variations, wind turbine steel must possess exceptional strength and durability. Its high fatigue resistance allows it to endure cyclic loading over the turbine's operational life, which can span up to 20-25 years. 2. Corrosion Resistance: Wind turbines often face corrosive saltwater and salt-laden air in coastal or offshore environments. As a result, the special steel used must exhibit superb corrosion resistance to prevent degradation and ensure long-term performance. 3. Weldability: The steel chosen for wind turbines should be suitable for welding processes, enabling efficient fabrication and assembly of turbine components. Excellent weldability streamlines construction and maintenance, reducing downtime and associated costs. 4. Low Temperature Toughness: Wind turbines are frequently situated in cold regions, such as arctic or mountainous areas. Consequently, the special steel employed must possess good low-temperature toughness, ensuring its mechanical properties remain intact even in frigid climates. 5. Magnetic Properties: Wind turbines utilize electrical components like generators and transformers, which operate within electromagnetic fields. The special steel used in these components should possess specific magnetic properties to minimize energy losses and maximize electrical system efficiency. 6. Cost-effectiveness: While meeting all the aforementioned requirements, the special steel employed in wind turbines must also be cost-effective. Striking a balance between performance and cost ensures the economic viability of wind energy projects. Meeting these requirements is vital for the long-term operation and sustainability of wind turbines, enabling them to generate clean and renewable energy efficiently.

- Q:What are the properties of alloy steel?

- Alloy steel is a type of steel that is made by combining iron with other elements, such as carbon, manganese, nickel, or chromium. It possesses unique properties that make it highly desirable for various applications. Some of the properties of alloy steel include high strength, excellent toughness, good corrosion resistance, and enhanced wear resistance. Additionally, alloy steel can be easily machined and welded, allowing for greater flexibility in its usage. The specific properties of alloy steel can vary depending on the particular elements added to it, leading to a wide range of alloys with different characteristics.

- Q:How does special steel perform in terms of magnetic permeability?

- Special steel typically has low magnetic permeability, meaning it does not easily allow the flow of magnetic fields through it. This property makes it suitable for applications where magnetic interference needs to be minimized or controlled, such as in electrical transformers or magnetic shielding.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SAE 1035 Carbon Steel Round Bar CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords