Rotaty Kiln Calcined Bauxite Powder with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Powder | Material: | Castable |

| SiO2 Content (%): | 0.5-15 | Al2O3 Content (%): | 55-95 | MgO Content (%): | 0.3 |

| CaO Content (%): | 0.3 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.1~0.3% |

| SiC Content (%): | 0.1~1.4% | Model Number: | Customer's Requirement | Brand Name: | cnbm |

Packaging & Delivery

| 1. 25KG or 50KG bag inside, jumbo bag outside or pallet 2. Wooden pallet and then polyethylene film is placed over it, finally the package is tied up with strips. | |

| Delivery Detail: | Within 20 days |

bauxite refractory powder

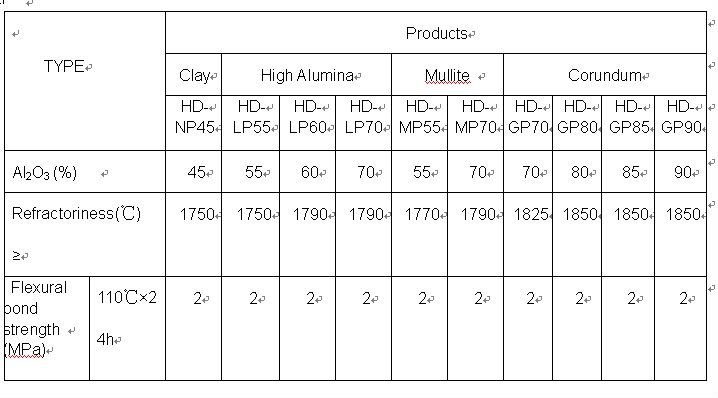

To meet the big size rotary kiln requirements, after long time research on rotary kiln refractory wearing and damage mechanism, Hongda company developed HD series rotary kiln refractory products, with advantages of good thermal stability, excellent resistance to abrasion and erosion, as well as long work life, insure the long time stable production of rotary kiln, create remarkable social and economic effects.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:Can the teflon material resist fire?

- Teflon material does not burn, but the heat resistance temperature of it is about 300℃.

- Q:which kind of refractory is commonly used in the industry

- Therefore it is known as special fire-resistant materials, such as yttria, high alumina raw material (sometimes neutral), olivine,which is used for alkalinity furnace, dolomite, and we roughly divided into several categories, beryllia, cerium oxide, these materials have a strong alkaline slag resistance, thorium oxide, lime, serpentine, which is picked from these refractory raw materials. the raw materials of basic refractory materials are mainly magnesia clay and titanium oxide, but because not many sources of raw materials, it can not be widely applied in the refractory industry, and we can analyze which kind of materal is processed by the pulverizer. There are many kinds of refractory materials, rotary?kiln can only be used in particular circumstances. These materials have a variety of slag resistance at different degrees. the main material of special refractories is zirconium oxide. the refractory clay is the most basic and most widely used raw material in the refractory industry.

- Q:Which fire-resistant materials have good viscidity?

- Viscidity is necessary for gunning mix, repair mix and bordering. It is too broad to which has good viscidity. Both gunning mix and repair mix are powder before adding water. Bordering also has little viscidity before heating. The question shoule be more specific.

- Q:Who knows how to divide the building fire grade and fire resistance grade?

- I hope to help you building fireproof rank division is one of the most basic measure in building fire safety technical measures, Building's fireproof rank is divided into class one, two, three, four according to China's architectural design specification. Fire-resistant capability of the highest level is the strongest; Fire resistance of four level of the weakest. The fire resistance level of a building depends on the combustion performance and fire resistance of the building components that comprise the building. The so-called building component refers to a series of basic components, such as wall, foundation, beam, column, floor, stair, ceiling and so on.

- Q:Why does refractory need to add coarse firstly and then add fine aggregate?

- Oh, adding coarse aggregate first is to select good material to make aggregate, and the rest cna be made into fine aggregate. Because if it contains impurities, once being sintered, the appearance will be affected, but fine aggregate does not have this impact.

- Q:what is the material of fixed first rate fire resistant window?

- Window frames and fireproofing glass, fire sealing strip, fireproofing glass mound layer, which is infexible fan, and the flexible fans have to plus folding and closing window cleaner. (3) window frames must be integral with the building, using wood or iron to connect the wall. After the installation of the steel frame, the cement mortar must be watered between the window frame and the wall, and it should conserve more than 24 hours before normal use.

- Q:How to classify fire resistance rating of brick-concrete structure?

- In order to ensure the safety of the building, the fire protection measures must be taken to make it have a certain degree of fire resistance, even if there is a fire, it will not cause too much damage. According to the national conditions of our country, and in the light of other countries standards, < high-rise civil building fire protection design specification > defines fireproof rank of high-rise civil buildings into level one and two; < code for fire protection design of buildings > divides the rank into level one, two, three, four, level one is the highest level, level four is the lowest. Besides that the minimum fire resistance of the building component is specified, buildings of fire resistance rating also specified requirements for combustion performance. Because the component with the same fire resistance limit is different, it is different in the fire.According to our country national standard < building design fire protection code >, the fire resistance rating of the building is divided into four levels. The fire resistance of a building is determined by the combustion performance and fire resistance of building components (such as beams, columns, floors, walls, etc.). Generally speaking, the fire resistance building of level one is a mixed structure of reinforced concrete structure or a mixture of brick wall and steel concrete structure; the fire resistance building of level two is a mixed structure of steel truss structure, reinforced concrete column and brick wall; the fire resistance building of level three is brick-wood structure made of wood roof and brick wall; the fire resistance building of level four is combustible structure which is composed of wood roof and non-combustible wall.

- Q:Can anyone say something about what A-level fire-proof decorative material is?

- The major products are material monomer A-level and composite A-level, now a lot of B-level material is wrapped in calcium silicate board. The foam cement overall composite is level A, such as phenolic aldehyde composite, as well as some of the foam paddings, monomer A-level includes rock wool, ultra-thin insulation panel and the like. But there are few products with real sound A level qualification. Many manufacturers are playing the edge ball with A-level fire rating examining reports and B-level system detection reports and records, but this situation will not last long, which will soon be clear.

- Q:How is the performance of refractory materials?

- It is a little difficult to answer. There are some requirement for refractory materials, such as fire resistance, softness, creep, thermal shock, abrasive resistance. Besides, requirements for construction performance include: Liquidity, plasticity and other linear change rate, volume density, strength (including high temperature) and all other important indicators must be tested the same conditions with the use of test conditions and test items like body density, strength, line changes in the basic project

- Q:What's the heat conductivity coefficient of fire-resistant material?

- There are many types of fire-resistant materials woth different thermal conductivity. The question should be more specific.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rotaty Kiln Calcined Bauxite Powder with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords