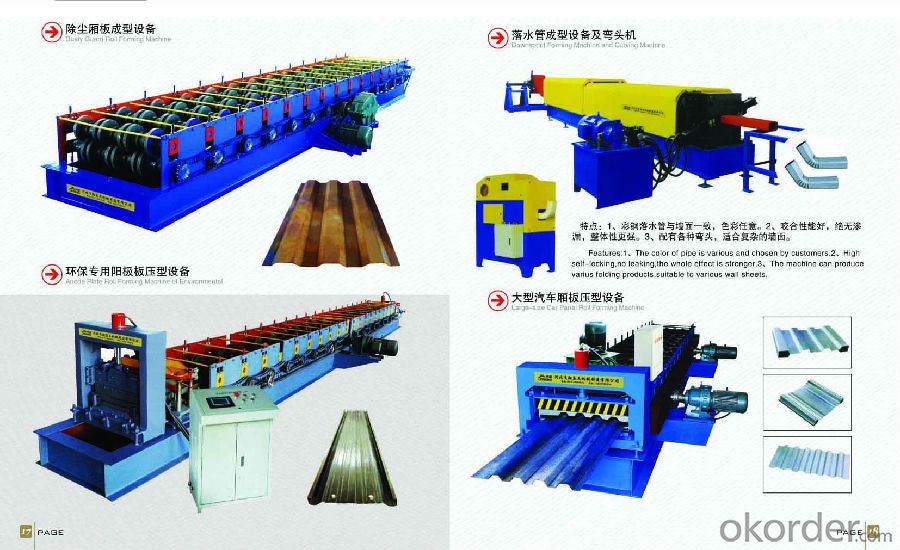

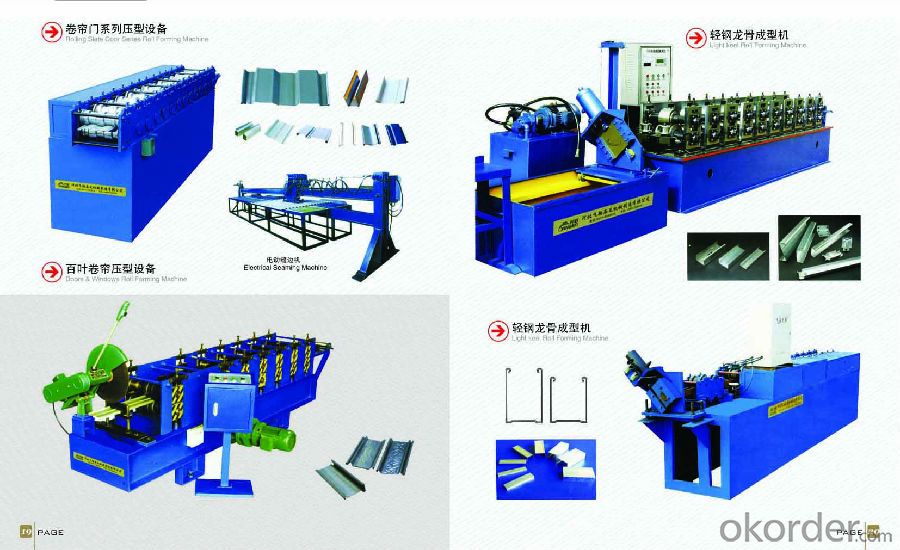

Roll Forming Machinery -PPGI PRL-7-SA3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

We can designthe line to make different kinds of panels in appearance, for wall panel androofing panel with various joint designs. Sandwichpanel, as a new building material,shows excellent performance oninsulation.

It is takingthe place of brick to be a main material for building now.

High speedslitting and cut to length can cut steel with thickness from 1mmto 16mm, if noneed slitting thickness up to 30mm.

Carry coil→loadcoil→de-coiling(pressingguide +opener)→entry、roughlevel→cutting→transition→guide→slitting (waste winding) →loopingstorage→pre-separating, damping→recoiling→packing→discharging→guide→leveling→fix size (end platefeeding)→cutting→discharging

The Manufacture Speed Of SandwichPanel:8.6m/min( frequency conversion to adjust speed)

2. TheThickness Of Sandwich Panel:30-200mm

3. TheThickness Of Steel : 0.4-0.8mm

4. TheLength Of The Production Line : about 120 meters

5. TheTotal Power Of The Production Line : 350 KW

6. TheLength Of The Double Belt Conveyer : 24m

- Q:Why does a bar break occur in a bar splitting machine?

- The uneven gap between the upper and lower blade produces bending: when the left and right gap is larger, the part of the impression is larger than the left and right side of the gap, so it shows a great curvature

- Q:Technical parameters of the slitting machine

- Strip material: metal plate, plain carbon steel, stainless steel, galvanized plate, aluminum strip, copper strip, cold rolled plate, hot rolled plate, etc.;

- Q:What is the difference between CNC slitting machine and slitting machine?

- CNC cutting machine, cutting machine and roll a large, similar to what size will directly cut. CNC slitting machine, then the main cut, there is a shaft discharge, and another shaft winding, the middle through the knife.

- Q:The technique of arranging knives in a slitting machine

- The cutting length can be set continuously, if the actual cutting length has errors, it is easy to calibrate by setting parameters.

- Q:What is the function and classification of the slitting machine?

- The most important are 14 inch Slitter, multi knife Slitter, round knife slitting machine, single pole slitting machine and so on. There is a pair of leather strip, aiming at PVC Slitter

- Q:What are the features of a metal slitting machine?

- Its main function is the wide web material according to the set length cut into narrow coil size, for days after the machining process to prepare.

- Q:What is a striping machine?

- What kind of slitting machine, flat knife or double-edged sword?. Laminating machine or slitting? This question also concerns the thickness of the original roll, for example, the original roll is 1 millimeters thick

- Q:Is the tape on the tape slitting machine a good one at the back or a good one in front?

- If you are concerned about the volume from the front. Mainly depends on your mother roll size, whether to change regularly, the quality of mother roll, how about, do not pay attention to its condition. Very few people ask this, I may not consider the full, you have the right to reference!

- Q:How do metal slitting machines cut out knives?

- The cutting skills of the slitting machine in the bar machine, and its Pai skills, mainly depends on the specific situation. If it is a good quality slitting machine, then it will be equipped with cutter software to carry out the correct arrangement.

- Q:How is the gap between the cutter and the cutter in the metal slitting machine measured without damaging the knife?

- A variety of equipment will be the entire corrugated cardboard production process organically combine, so that its continuous production. The traditional methods of combined production of more units and single machines not only have high production efficiency, low labor intensity, but also operate centralized control, which is simple, safe and low noise. The most important thing is that the corrugated paperboard produced is of high quality.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roll Forming Machinery -PPGI PRL-7-SA3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products