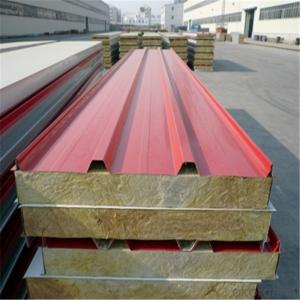

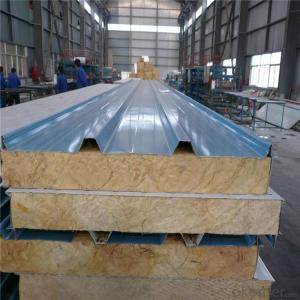

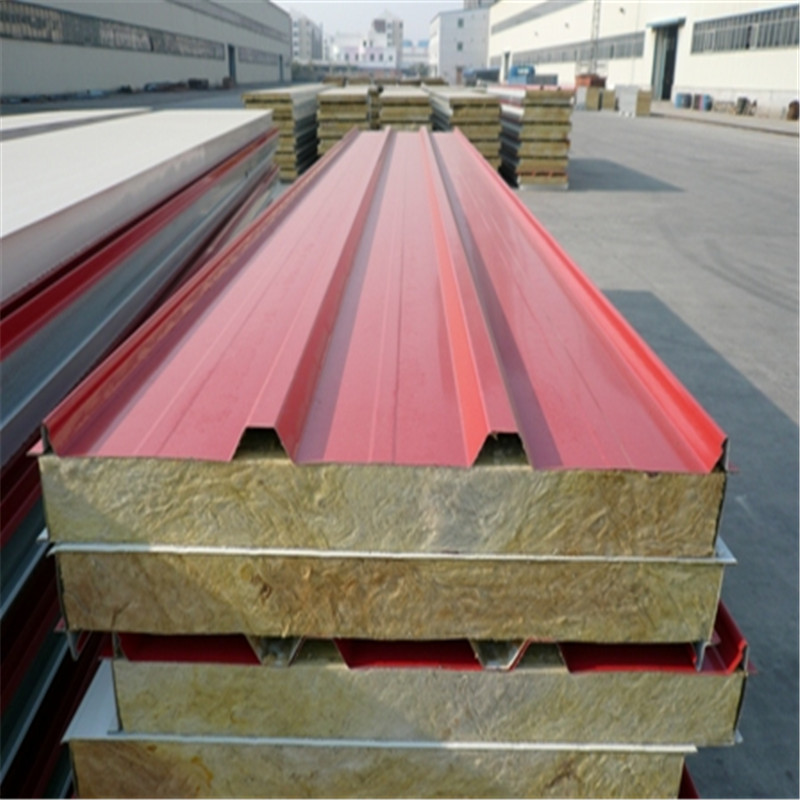

Rock wool sandwich panels for low cost wall cladding and roof of prefabricated house

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock wool sandwich panels for low cost wall cladding and roof of prefabricated house

Description of rock wool sandwich panels:

The rock wool, which we call it “mineral wool”, is made from blast furnace slag, phosphorus slay, and coal ash through fusion. This is unreal rock wool with the features of high slag and has a lot of dust.

Rock Wool Sandwich Panel advantages

For more than ten years, sandwich panels with rock wool cores have been used successfully in a quick way of construction, having lots of advantages compared to conventional building systems:

Fast installation and convenient handling

Crane assembly and no scaffolding required

No thermal bridges and good thermal insulation properties

Plenty of design with choice of profiles and colours

Panels can be installed horizontally or vertically

Reliable robust mechanical performance

Outstanding non-combustible and acoustic performance

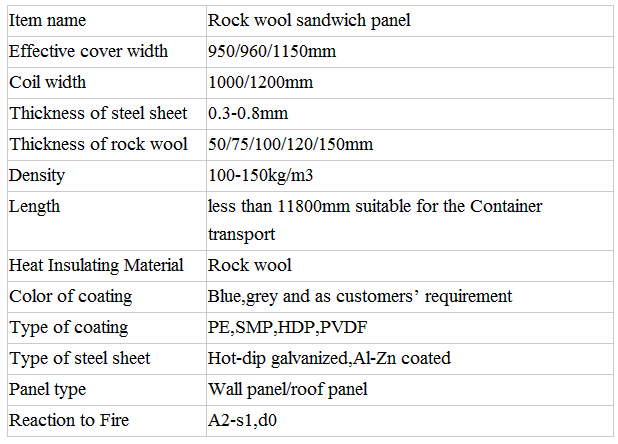

Specification of rock wool sandwich panels:

Applications

Rock Wool Sandwich panels cover all applications in steel building construction and prefabricated houses: external walls, roofs, partitions, ceiling panels, fire rated and acoustic sandwich panels for workshops,warehouse, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

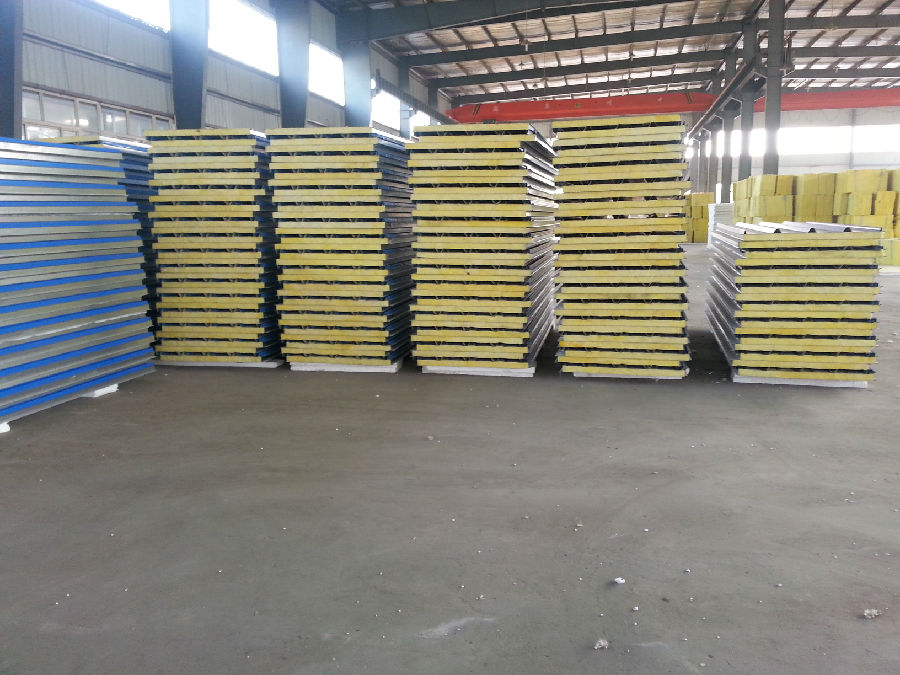

Workshop of rock wool panels

- Q:Can the rock wool sandwich panel be used as a ceiling?

- Rock wool sandwich panels can do ceiling. Ceiling (English name: sprung roof) refers to the housing living environment of the top decoration. Simply put, refers to the decoration of the ceiling, is an important part of interior decoration. Ceiling with insulation, insulation, sound insulation, sound absorption of the role, but also electrical, ventilation and air conditioning, communications and fire, alarm pipeline equipment and other projects hidden layer. Home decoration ceiling is a common part of home improvement. The ceiling is different according to the material of the decorative plate, and the classification is not the same. Ceiling decoration materials is the main basis for distinguishing the name of the ceiling, mainly: light steel keel gypsum board ceiling, gypsum board ceiling, mineral wool board ceiling, plywood ceiling, profiled long strip of aluminum slab ceiling, Glass ceiling, aluminum honeycomb perforation sound-absorbing panels such as ceiling. In the whole room decoration occupies a very important position on the top of the room for the appropriate decoration, not only to beautify the indoor environment, but also create a colorful interior space art image. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

- Q:Rock wool sandwich board how, what are the advantages?

- Compared to the foam sandwich panel, he fire, strength better. Compared to polyurethane sandwich panels, he is cheap, fireproof It is more resistant to heat than glass wool Compared to the hollow glass magnesium board, his thermal performance is good But there is a certain amount of dust Now if you want to achieve the best results Rockwool Magnesium is your best choice

- Q:Can Caoyan sandwich wall be installed? How to install Thank you

- Take a look at the drawing

- Q:in a sandwich panels is there a formula to calculate the amount of foam in the square meter?

- V =1*t where t is the thickness of the foam in meters.

- Q:How does a fire spread in a polyurethane panel (sandwich panel) made building ?

- all the other things will burn, like the carpets, desks and everything else

- Q:There is a comprehensive building, a two-story canteen, three-story activity room, the roof for the Caigang sandwich panel roof, the building fire rating for the two, the roof sandwich board design using polystyrene foam sandwich panels can?

- Can not. Polystyrene foam sandwich panels are mostly flammable and flammable, preferably flame retardant, and the burning properties of their materials do not meet the requirements of Grade II refractory grade buildings. Our province has been a few cases of Caigang sandwich panel roof fire cases, due to sandwich material led to the rapid expansion of fire.

- Q:What kind of sandwich board is the phosphorous magnesium plate

- Magnesium board is a new type of multi-functional building materials. Using magnesium oxide, magnesium chloride as the main raw material, and a certain percentage of perlite, glass fiber mesh, wood fiber and other mixed processing. With light, fire, high strength, sound absorption, heat insulation, non-toxic harmless, corrosion-resistant, not mildew and so on. Can be used as a wall, ceiling ceiling, floor liner and so on.

- Q:100 thick rock wool sandwich panels (1.1 meters from the purlin) can do the roof? Floor thickness 0.8, panel thickness 1, so feasible?

- Principle is possible. To see you that support beam can bear the weight, if you can, then single-color steel tile no problem, and finally walk in the distance beam so tile is not deformed. The

- Q:anxious! Will the polyurethane sandwich panels of various parameters, plant design!

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q:V950 color steel rock wool sandwich panel and v960 color steel rock wool sandwich board what does it mean

- Is the practical width of the tile of 950 watts a meter long is 0.95 level 960 is 0.96 level

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rock wool sandwich panels for low cost wall cladding and roof of prefabricated house

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords