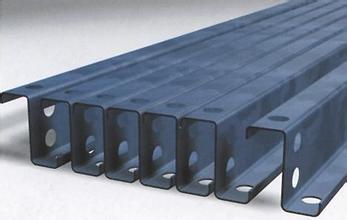

Quality Steel Z-Channel (Thickness: 2.0mm)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 PCS

- Supply Capability:

- 2000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high Quality Steel Z-Channels (Thickness: 2.0mm) at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Quality Steel Z-Channels (Thickness: 2.0mm) are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-25 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q195-Q345/SPCC

Manufacture: Cold forming

Shape: Z-channel

Dimensions:

Base: 35mm – 400mm

Width: 15mm – 25mm

Height: 80mm – 350mm

Thickness: 0.3mm – 6mm

Place of Origin: Tianjin, China

Certifications: ISO 9001:2000, TUV

Production: 20,000 tons/month

Processing Available: Threading, coupling, plastic cap protection

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:How do steel channels hold up against extreme temperatures?

- Steel channels are known for their exceptional strength and durability, making them highly capable of withstanding extreme temperatures. The properties of steel, such as its high melting point and thermal conductivity, allow steel channels to maintain their structural integrity even when exposed to extreme heat or cold. When subjected to high temperatures, steel channels expand at a slower rate compared to other materials, which helps to minimize the risk of deformation or failure. This resistance to thermal expansion is due to the low coefficient of linear expansion of steel. This property ensures that steel channels maintain their shape and structural stability even under extreme temperature fluctuations. Furthermore, steel channels possess excellent fire resistance. Steel has a high melting point, typically ranging from 1370°C to 1530°C (2500°F to 2800°F), which means it can withstand intense heat without losing its structural integrity. This makes steel channels a reliable choice in applications where fire protection is crucial, such as in buildings, bridges, or industrial structures. On the other hand, steel also exhibits good performance in cold temperatures. Unlike some materials that become brittle or weak when exposed to low temperatures, steel retains its strength and ductility. This makes steel channels suitable for use in environments with extremely cold temperatures, such as in arctic regions or cryogenic facilities. In conclusion, steel channels are highly resilient to extreme temperatures due to their low coefficient of linear expansion, high melting point, and overall durability. Whether exposed to intense heat or cold, steel channels maintain their structural integrity and provide long-lasting performance, making them a reliable choice in various applications.

- Q:How do steel channels contribute to the overall cost-effectiveness of a building?

- Steel channels contribute to the overall cost-effectiveness of a building by providing structural support and reducing the need for excessive materials. These channels are versatile and can be easily fabricated to fit specific requirements, which reduces waste and construction time. Additionally, steel channels have high strength-to-weight ratio, allowing for lighter building designs and lower transportation costs. Their durability and resistance to corrosion also result in long-term cost savings by minimizing maintenance and replacement expenses.

- Q:Which kind of wind resistance is better for square tube, square tube or channel steel?

- Square pipe and channel steel that load-bearing better 1, the same thickness and area, square superior to channel. 2, if the channel is closed to a rectangular tube, then the channel is better than the square tube.

- Q:How do steel channels perform in acoustic applications?

- Steel channels can be used effectively in acoustic applications due to their structural properties. The rigidity and strength of steel make it an ideal material for creating sound barriers and minimizing vibrations. Steel channels can be used to construct walls, partitions, or ceilings that help to isolate sound and prevent its transmission. The dense nature of steel helps to absorb and dampen sound waves, reducing their intensity and preventing reverberation. This is especially beneficial in environments where noise control is critical, such as recording studios, theaters, or conference rooms. Moreover, steel channels can be combined with soundproofing materials or insulation to enhance their acoustic performance. By adding layers of materials such as foam, fiberglass, or acoustic panels, the steel channels can further reduce sound transmission and improve the overall acoustic quality of a space. Additionally, steel channels provide stability and durability, ensuring that the acoustic structures remain intact over time. They can withstand heavy loads and offer resistance to fire, making them a reliable choice for acoustic applications. However, it is important to note that steel channels alone may not provide sufficient soundproofing in certain high-noise environments. The effectiveness of steel channels in acoustic applications also depends on other factors such as the design of the space, the quality of construction, and the use of additional soundproofing techniques. Overall, steel channels can be a valuable component in achieving sound control and acoustic performance in various applications. Their strength, rigidity, and ability to dampen sound make them a suitable choice for creating sound barriers and minimizing noise transmission.

- Q:Own attic, choose I-beam or channel?

- Oneself take attic, suggest to choose I-beam, and choose GB steel, because stainless steel in non GB is more.I-beam is a kind of economical section steel with better mechanical performanceFeatures: I-beamWide flange and large lateral rigidity. Good bending resistance.The two surfaces of the flanges are mutually parallel so that the connection, processing and installation are simple and convenient.Compared with the general steel, the utility model has the advantages of low cost, high precision, little residual stress, no expensive welding materials and welding seam detection, and the cost of steel structure production is saved by about 30%.Under the same section load, the weight of hot-rolled H steel structure is less than that of traditional structure 15%-20%.Compared with the concrete structure, the I-beam structure can increase the use area of 6%, while the weight of the structure can be reduced by 20% and 30%, and the internal force of the structural design can be reduced.The I-beam can be processed into T steel, and the castellated beams can form various section forms to meet the demands of engineering design and manufacture.

- Q:How do steel channels contribute to the overall structural integrity of a building?

- Steel channels play a crucial role in enhancing the overall structural integrity of a building. These structural components are often used in construction projects due to their exceptional strength, durability, and versatility. Steel channels are typically C-shaped or U-shaped beams made from steel, which provides numerous benefits for the structural stability of a building. Firstly, steel channels distribute and transfer loads effectively. Due to their shape, steel channels are capable of supporting heavy loads and distributing them evenly across multiple points. This even distribution of weight prevents concentrated stress points, reducing the risk of structural failure. Steel channels also have a high load-bearing capacity, allowing them to withstand substantial forces and ensure the overall stability of the building. Secondly, steel channels provide resistance against bending and twisting forces. Their shape and material composition enable them to resist deformation under pressure, ensuring that the building maintains its structural integrity even during extreme conditions such as earthquakes or strong winds. By preventing excessive deflection, steel channels help keep the building safe and secure. Furthermore, steel channels enhance the rigidity and stability of the structure. By connecting various components of the building, such as beams, columns, and walls, steel channels effectively eliminate any potential weak points or gaps. This comprehensive integration of different elements contributes to the overall strength and stability of the building, preventing any potential structural failures. Lastly, steel channels offer flexibility in design and construction. They can be easily customized to fit specific architectural requirements, allowing for innovative and efficient building designs. The versatility of steel channels enables architects and engineers to optimize the strength and stability of the structure while maintaining aesthetic appeal. In summary, steel channels significantly contribute to the overall structural integrity of a building by distributing and transferring loads effectively, resisting bending and twisting forces, enhancing rigidity and stability, and providing design flexibility. Their strength, durability, and versatility make them an indispensable component in modern construction, ensuring the safety and longevity of buildings.

- Q:Can steel channels be used for mezzanine floors?

- Yes, steel channels can be used for mezzanine floors. Steel channels are commonly used in construction for their strength and durability. They can be used as the primary structural support for mezzanine floors, providing a sturdy framework for the elevated platform. Steel channels can be easily fabricated and installed, making them a practical choice for mezzanine floor construction. Additionally, steel channels can withstand heavy loads and provide sufficient support for various activities such as storage, offices, or additional workspaces. Overall, steel channels are a suitable and commonly used material for constructing mezzanine floors.

- Q:120*53*5.5 what's the weight of channel steel?

- 120 * 53 * 5.5 12 # 12.06kg/m

- Q:Do steel channels have any specific load distribution characteristics?

- Yes, steel channels do have specific load distribution characteristics. Steel channels are commonly used in structural applications as they provide excellent strength and load-carrying capacity. The load distribution characteristics of steel channels depend on their shape, size, and orientation. Steel channels typically have a C-shaped cross-section, with a flat back and two perpendicular flanges. The load distribution characteristics of steel channels are primarily influenced by the flanges. The flanges act as beams that resist bending and carry the applied load. The load is distributed along the length of the flanges, creating a load path that transfers the load to the supports or other structural elements. The load distribution characteristics of steel channels are also influenced by the size and orientation of the channel. Larger channels with wider flanges can distribute the load over a larger area, reducing the stress concentration. Additionally, the orientation of the channel, whether it is vertical or horizontal, can affect the load distribution characteristics. It is important to consider the load distribution characteristics of steel channels during the design and analysis of structures. Engineers need to ensure that the channels are properly sized and oriented to adequately distribute the applied loads. By considering these characteristics, steel channels can effectively distribute the load and contribute to the overall structural integrity and stability of a construction project.

- Q:What are the different fabrication techniques used for steel channels?

- There are various fabrication techniques used for manufacturing steel channels, each with its own advantages and applications. Some of the commonly used techniques include hot rolling, cold rolling, and press braking. Hot rolling is a popular method where steel is heated above its recrystallization temperature and then passed through a series of rollers to shape it into the desired channel profile. This technique allows for high production rates and can produce channels with consistent dimensions and excellent surface finish. Cold rolling, on the other hand, involves the deformation of steel at room temperature. The process starts with hot-rolled steel, which is subsequently passed through rollers under high pressure. Cold rolling can result in greater dimensional accuracy, improved surface finish, and increased strength compared to hot rolling. Press braking is another fabrication technique used for steel channels. In this method, a hydraulic press is used to bend the steel sheet into the desired channel shape. This technique is particularly suitable for producing channels with complex shapes or when only a small quantity of channels is required. Other fabrication techniques for steel channels include laser cutting, plasma cutting, and welding. Laser cutting uses a high-powered laser beam to cut the steel sheet into the desired channel profile accurately. Plasma cutting, on the other hand, utilizes a jet of hot plasma to cut through the steel. Both techniques offer precise and fast cutting processes. Welding is often used to join multiple steel sections together to create larger and more complex channel structures. Various welding methods, such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and arc welding, are employed based on the specific requirements of the project. Overall, the choice of fabrication technique for steel channels depends on factors such as the desired channel profile, production volume, dimensional accuracy, surface finish, and project requirements. By utilizing these different techniques, manufacturers can create steel channels that meet a wide range of applications in construction, manufacturing, and other industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Quality Steel Z-Channel (Thickness: 2.0mm)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 PCS

- Supply Capability:

- 2000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords