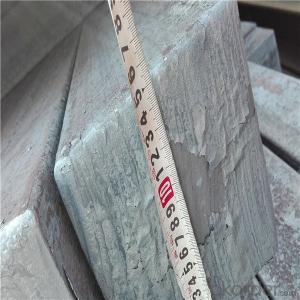

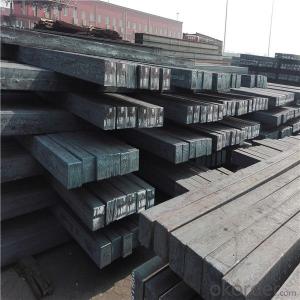

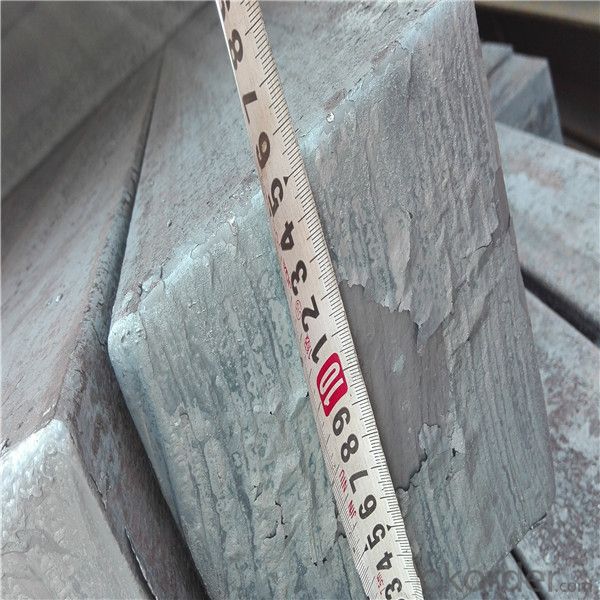

Q275 Square Steel Billets factory sale directly

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still

require a series of shaping and molding procedures such as hot and cold working, milling and cutting

before they are sold in hardware stores, or used for different applications. The unformed billets,

however, can be used in striking currency such as coins and as reserves, similar to gold bars.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:How are steel billets tested for internal defects?

- Steel billets undergo various non-destructive testing methods to check for internal defects. Ultrasonic testing (UT) is a commonly used method. It involves transmitting high-frequency sound waves into the billet and analyzing the reflections to identify cracks, voids, or inclusions. UT provides accurate information about the defects' size, location, and nature. Magnetic particle inspection (MPI) is another method employed. It magnetizes the billet and applies iron particles to its surface. If there are internal defects, the magnetic field causes the particles to gather around them, making them visible and detectable. Eddy current testing (ECT) is also used to assess the internal quality of steel billets. It creates eddy currents within the material using electromagnetic induction. Any changes in electrical conductivity or magnetic permeability caused by internal defects are detected by analyzing the induced current's variations. Radiographic testing (RT) is additionally utilized to inspect the steel billet's internal structure. X-rays or gamma rays are directed towards the billet, and the resulting radiographic image reveals voids, cracks, or inclusions. Dye penetrant testing and visual inspection can be used to detect superficial and near-surface defects. These methods involve applying liquid or dye to the billet's surface, which seeps into cracks or surface irregularities, making them visible under specific lighting conditions. Overall, a combination of these non-destructive testing methods ensures the quality and integrity of steel billets. They effectively detect any internal defects that could compromise the billet's structural integrity and performance.

- Q:What are the different types of steel billet handling equipment?

- There are several different types of steel billet handling equipment used in various stages of the steel production process. These equipment are designed to efficiently move and transport steel billets, which are semi-finished metal products used for further processing. 1. Overhead Cranes: Overhead cranes are commonly used in steel mills and foundries for the handling and transportation of steel billets. These cranes have a high lifting capacity and can move billets from one location to another within the facility. 2. Mobile Cranes: Mobile cranes are versatile and can be used for handling steel billets in both indoor and outdoor environments. They are equipped with hydraulic systems for lifting and maneuvering heavy loads. 3. Forklifts: Forklifts are commonly used in warehouses and storage facilities to handle steel billets. They have forks at the front that can be raised and lowered to lift and move the billets. 4. Grab Buckets: Grab buckets are used for handling bulk materials, including steel billets. They have a bucket-like structure that can be opened and closed to grab and release the billets. These are often used in ports and shipping yards for loading and unloading billets from ships. 5. Conveyor Systems: Conveyor systems are used for continuous movement of steel billets along a predefined path. They can be used to transport billets between different stages of the production process or to load and unload them from trucks or trains. 6. Roller Tables: Roller tables are used for transferring steel billets from one conveyor or machine to another. They typically consist of a series of rollers that allow for smooth and controlled movement of the billets. 7. Magnetic Lifters: Magnetic lifters use an electromagnetic field to lift and transport steel billets. They are particularly useful when handling ferrous materials, as the magnetic force allows for secure gripping and easy movement. 8. Palletizers: Palletizers are used to stack and organize steel billets on pallets. They can automatically arrange the billets in a specific pattern, making them suitable for storage or transportation. Each type of equipment has its own advantages and is used in specific applications based on the requirements of the steel production process. The selection of the appropriate handling equipment depends on factors such as the size and weight of the billets, the distance they need to be transported, and the specific needs of the facility.

- Q:Can steel billets be used in the production of railway tracks?

- Certainly! Steel billets have the capability to be utilized in the fabrication of railway tracks. Known as semi-finished goods, steel billets are commonly employed in the production of a wide range of steel items, including railway tracks. Due to the heavy weight and movement of trains, railway tracks necessitate remarkable strength and durability. Steel billets, typically composed of carbon steel or alloy steel, offer the required strength and structural integrity indispensable for railway tracks. These billets can undergo further processing and shaping through hot rolling or alternative manufacturing methods to transform into rails. Once the final rails are ready, they are installed onto the railway tracks, providing a safe and smooth surface for the movement of trains. Consequently, steel billets are an indispensable raw material in the manufacturing of railway tracks.

- Q:What are the main factors affecting the fatigue strength of steel billets?

- The main factors affecting the fatigue strength of steel billets include the material composition and quality, the presence of surface defects or imperfections, the applied stress levels, the frequency or rate of the applied cyclic loading, and the temperature conditions during the fatigue process.

- Q:How are steel billets shaped into other forms?

- Steel billets are shaped into other forms through a process called hot rolling. Hot rolling involves passing the steel billet through a series of heated rollers that compress and shape the billet into the desired form. First, the steel billet is heated to a high temperature in a furnace. This heat treatment makes the steel more malleable and easier to shape. Once the billet reaches the desired temperature, it is fed into a rolling mill. In the rolling mill, the billet is passed through a series of rollers that apply pressure and force to shape the steel. These rollers can have various shapes and sizes depending on the desired outcome. As the billet passes through the rollers, it is gradually shaped into the desired form, such as sheets, bars, or beams. The rolling process not only shapes the steel but also improves its mechanical properties. It refines the grain structure, enhances the strength and toughness, and removes any internal defects. This makes the steel more suitable for various applications, such as construction, automotive, and machinery. After the hot rolling process, the steel is often further processed through cold rolling, which involves passing it through cold rollers to refine its surface finish and dimensions. Additionally, other secondary operations like cutting, bending, and welding may be performed to further shape the steel into the desired end product. Overall, hot rolling is a crucial process in shaping steel billets into other forms. It allows for the production of a wide range of steel products, each with its specific shape, size, and mechanical properties, meeting the diverse needs of industries worldwide.

- Q:How do steel billets contribute to the aerospace industry?

- The aerospace industry heavily relies on steel billets as they serve as the essential raw material for producing various components and structures used in aircraft. These semi-finished metal forms, created through continuous casting, play a crucial role in the manufacturing process. Once formed, the steel billets undergo further processing using techniques like forging, machining, and heat treatment to transform them into different aerospace components. This allows for the customization of billets into specific forms like engine parts, landing gear components, structural frames, and other critical elements. Utilizing steel billets in the aerospace industry offers numerous advantages. Firstly, steel is renowned for its strength, durability, and exceptional mechanical properties, making it an ideal material for applications that prioritize safety and reliability, such as in the aerospace sector. Steel billets can withstand extreme conditions like high temperatures, pressure, and stress, making them suitable for critical parts that need to perform under demanding circumstances. Moreover, steel billets provide cost-effectiveness and versatility in manufacturing. Steel is readily available and comparatively more affordable than other metals used in aerospace applications. Additionally, the ability to shape and process steel billets into various forms and sizes allows for flexibility in designing and producing aerospace components, ensuring they meet specific requirements and standards set by aircraft manufacturers. Another significant contribution of steel billets to the aerospace industry is their compatibility with advanced manufacturing technologies. Steel can be easily machined, welded, and joined, facilitating the integration of complex features and structures in aerospace components. This compatibility with modern manufacturing techniques allows for the production of lightweight yet robust parts, enhancing overall fuel efficiency and aircraft performance. In conclusion, steel billets are indispensable in the aerospace industry as they provide the crucial raw material for manufacturing critical components and structures used in aircraft. Their high strength, durability, cost-effectiveness, and compatibility with advanced manufacturing technologies make steel billets an essential element in constructing safe, reliable, and efficient aerospace systems.

- Q:How do steel billets contribute to the manufacturing of construction supplies?

- Steel billets play a crucial role in the manufacturing of construction supplies. These billets are semi-finished products that are typically obtained through the process of continuous casting or ingot casting. They are essentially long, rectangular-shaped bars of steel that serve as the raw material for various construction products. One of the primary ways steel billets contribute to the manufacturing of construction supplies is through the production of reinforced bars, commonly known as rebars. Rebars are used extensively in the construction industry to provide strength and structural integrity to concrete structures such as buildings, bridges, and roads. By using steel billets, manufacturers can produce rebars of different sizes and lengths to meet specific construction requirements. Additionally, steel billets are also used in the production of various other construction supplies such as wire rods, pipes, and structural sections. Wire rods, for example, are used in the manufacturing of wire mesh, nails, and other reinforcing materials. Steel billets are also utilized to produce pipes that are widely used in plumbing, drainage systems, and infrastructure projects. Furthermore, structural sections made from steel billets are utilized to create beams, columns, and other load-bearing components in construction projects. The use of steel billets in the manufacturing of construction supplies ensures the final products possess excellent strength, durability, and resistance to corrosion. This is crucial for construction materials as they need to withstand various environmental factors and heavy loads. The versatility of steel billets allows manufacturers to produce a wide range of construction supplies that can meet the specific needs and requirements of different construction projects. In summary, steel billets are instrumental in the manufacturing of construction supplies. They serve as the raw material for producing rebars, wire rods, pipes, and structural sections, all of which are essential components in construction projects. The use of steel billets ensures that these construction supplies possess the necessary strength, durability, and resistance to corrosion, making them suitable for a wide range of construction applications.

- Q:Can steel billets be used in the production of aerospace components?

- Indeed, the utilization of steel billets is feasible for the manufacturing of aerospace components. These semi-finished steel products can undergo further processing to attain an assortment of shapes and sizes. Notably, their application is widespread across industries such as aerospace, automotive, and construction. Within the aerospace sector, steel billets serve as the foundation for fabricating shafts, gears, and structural parts. Nevertheless, it is imperative to acknowledge that the steel variant employed in aerospace must adhere to stringent criteria encompassing strength, durability, high-temperature resistance, and corrosion resistance. Consequently, steel billets employed in aerospace production necessitate supplementary treatments such as heat treatment, machining, and surface finishing to attain the desired properties and dimensions. Overall, while the utilization of steel billets is feasible for aerospace component manufacturing, it is crucial to ensure that the steel material and manufacturing processes conform to the stipulated specifications and standards to guarantee safety and performance within the aerospace industry.

- Q:How do steel billets contribute to the manufacturing of medical equipment?

- Steel billets are a crucial component in the manufacturing of medical equipment as they are used to create various parts and components, such as surgical instruments, implants, and medical devices. The high-strength and durability of steel make it ideal for ensuring the reliability and longevity of these critical medical tools. Additionally, steel billets can be easily molded and shaped into the desired form, allowing manufacturers to create intricate and precise designs necessary for medical equipment.

- Q:What are the different types of steel billet rolling techniques?

- There are several different types of steel billet rolling techniques, including hot rolling, cold rolling, and continuous casting.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q275 Square Steel Billets factory sale directly

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords