PVC Waterproofing Membrane with Polyester Scrim Layer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Membrane with Polyester Scrim Layer

Product Description of PVC Waterproofing Membrane with Polyester Scrim Layer:

PVC waterproofing membrane is an excellent high-quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti aging agent, and stabilizer and other processing aids through extrusion and molding. As the highly recommended product by the Ministry of Construction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low-temperature performances, good resistance to weathering and root

penetration, and long service life.

Features of PVC Waterproofing Membrane with Polyester Scrim Layer:

1.Long service life and weathering resistance; and the materials can be used for 30 years on the roof and 50 years underground.

2. High tensile strength, great elongation, and small size change during heat treatment.

3. Good low temperature flexibility and adaptability to environmental temperature changes.

4. Good resistance to root penetration. It can be made for green roofs.

5. Excellent resistance to puncture and impact.

6. Convenient for construction (can be welded), solid and reliable, and Eco-friendly.

7. Strong resistance to chemical corrosion, suitable for special occasions.

8. Good plasticity, convenient and quick corner detail treatment. Easy maintenance and low cost.

9.After 2,000 hours of manual weathering verification

Classification of PVC Waterproofing Membrane with Polyester Scrim Layer:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Membrane with Polyester Scrim Layer:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Membrane with Polyester Scrim Layer:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Membrane with Polyester Scrim Layer:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

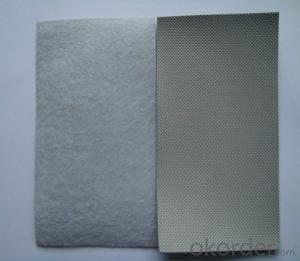

Images of PVC Waterproofing Membrane with Polyester Scrim Layer:

FAQ of PVC Waterproofing Membrane with Polyester Scrim Layer:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q:Can a waterproofing membrane be used for residential swimming pools?

- Indeed, residential swimming pools can benefit from the use of a waterproofing membrane. These membranes are frequently employed in construction to safeguard against water infiltration and can be utilized on diverse surfaces including concrete, tile, and metal. By forming a barrier, they effectively prevent water from permeating the pool structure, thereby preserving its integrity and averting leaks. Furthermore, waterproofing membranes afford protection against other types of harm such as corrosion and deterioration resulting from chemicals or adverse weather conditions. Consequently, it is crucial to choose a top-notch waterproofing membrane specifically designed for swimming pool applications in order to guarantee long-lasting safeguarding and durability.

- Q:Can waterproofing membranes be used on concrete surfaces?

- Concrete surfaces can indeed benefit from the use of waterproofing membranes. These membranes are specifically designed to create a barrier against water penetration. They are often employed on concrete surfaces to safeguard them against water damage. Typically, these membranes are composed of rubber, PVC, or bitumen and can be applied to the concrete surface either in a liquid or sheet form. Once applied, the membrane forms a strong and continuous waterproof layer that effectively prevents water from seeping into the concrete. This proves to be particularly advantageous in areas that frequently come into contact with water, such as basements, bathrooms, or outdoor concrete structures. By preventing water-related issues such as cracking, spalling, or mold growth, waterproofing membranes effectively prolong the lifespan of concrete surfaces.

- Q:Can a waterproofing membrane be used in bathrooms or showers?

- Yes, a waterproofing membrane can be used in bathrooms or showers. Waterproofing membranes are specifically designed to prevent water penetration and protect the underlying surfaces from moisture damage. They are commonly used in wet areas like bathrooms and showers to ensure long-lasting waterproofing and prevent water leakage.

- Q:Can a waterproofing membrane be used on roofs with slope?

- Roofs with slope can use a waterproofing membrane. It is commonly applied on sloped roofs to add an extra layer of protection against water infiltration. The membrane is typically placed beneath the roofing materials and acts as a barrier to stop water from seeping into the roof structure. This is particularly crucial for sloped roofs as water runoff is faster and may lead to leaks or damage. The waterproofing membrane is designed to be flexible and is able to adapt to the roof's slope without compromising its effectiveness. Moreover, it also enhances the roof's durability and lifespan by preventing moisture-related problems like rot or mold growth.

- Q:Can a waterproofing membrane be used for bridges and overpasses?

- Yes, a waterproofing membrane can be used for bridges and overpasses. Waterproofing membranes are commonly used in infrastructure projects to protect the structures from water damage and extend their lifespan. They create a barrier against moisture, preventing water infiltration and protecting the underlying materials from corrosion and deterioration. By applying a waterproofing membrane to bridges and overpasses, it helps ensure their durability and structural integrity.

- Q:Can a waterproofing membrane be applied to both interior and exterior surfaces?

- Both interior and exterior surfaces can benefit from the application of a waterproofing membrane. Its main objective is to safeguard against water infiltration and shield the underlying surfaces. Regardless of whether it is used indoors or outdoors, the membrane serves the same purpose of establishing a barrier against moisture. Basements and crawl spaces commonly utilize interior waterproofing membranes to prevent water from seeping into the building interior. On the other hand, exterior waterproofing membranes are typically applied to the outside walls and foundations to guard against water penetration from rain, groundwater, and other external sources. Both types of membranes are engineered to be long-lasting, adaptable, and water-resistant, ensuring the durability and structural soundness of the surfaces they are applied to.

- Q:How thick should a waterproofing membrane be?

- The thickness of a waterproofing membrane is influenced by various factors, including the type of membrane, specific application, and desired level of protection. Typically, the thickness of a waterproofing membrane can range from 0.5mm to 4mm. For waterproofing applications below ground, like basements or foundations, it is generally recommended to use a thicker membrane to provide better defense against water infiltration and potential hydrostatic pressure. In these cases, a membrane thickness of approximately 2mm to 4mm is commonly utilized. Conversely, for above-ground applications such as roofs or balconies, a thinner membrane is often sufficient. A thickness of 0.5mm to 2mm is typically satisfactory in creating a reliable waterproofing barrier. It is important to understand that the thickness alone does not solely determine the effectiveness of a waterproofing membrane. Other factors, such as the material's composition, quality, and installation techniques, also significantly contribute to ensuring a long-lasting and efficient waterproofing solution. Therefore, consulting with a professional waterproofing expert or manufacturer is essential in order to determine the appropriate thickness based on the specific requirements and conditions of the project.

- Q:Is a waterproofing membrane resistant to hydrochloric acid or other corrosive substances?

- Waterproofing membranes are designed to resist water penetration and are commonly used as a barrier against moisture. However, it is important to understand that the resistance of a waterproofing membrane to hydrochloric acid or other corrosive substances may vary depending on the specific material used. Some waterproofing membranes, like those made from bituminous or rubberized asphalt materials, have a higher resistance to chemicals such as hydrochloric acid. These membranes are often utilized in industrial settings where exposure to corrosive substances is frequent. They are specifically engineered to endure the effects of these substances and offer long-lasting protection. On the contrary, other types of waterproofing membranes, such as those composed of polyvinyl chloride (PVC) or high-density polyethylene (HDPE), may have a lower resistance to corrosive substances like hydrochloric acid. These membranes are typically employed in less demanding applications where chemical exposure is not a significant concern. Regardless, it is essential to refer to the manufacturer's specifications and guidelines when assessing the resistance of a particular waterproofing membrane to hydrochloric acid or other corrosive substances. The manufacturer can provide detailed information on the membrane's chemical resistance properties and offer guidance on its suitability for specific applications involving corrosive substances.

- Q:Is a waterproofing membrane resistant to mold and mildew growth?

- Yes, a waterproofing membrane is resistant to mold and mildew growth. This is because waterproofing membranes are specifically designed to create a barrier against moisture, preventing water from seeping through and causing mold and mildew to grow. By effectively sealing off the area, these membranes eliminate the conditions necessary for mold and mildew to thrive, such as dampness and moisture. However, it is important to note that while the membrane itself is resistant to mold and mildew growth, it does not guarantee complete protection against these issues. Proper installation, regular maintenance, and ensuring proper ventilation are also crucial in preventing mold and mildew growth in the long term.

- Q:Can a waterproofing membrane be used for concrete bridge decks?

- Concrete bridge decks can indeed benefit from the use of a waterproofing membrane. This type of membrane is a thin material layer that gets applied to the surface of the bridge deck. Its purpose is to prevent water infiltration and safeguard the concrete against deterioration caused by moisture. The membrane is designed to be both flexible and durable, creating a barrier against water while still allowing for the bridge deck's natural movement and expansion. Generally, it is applied in multiple layers and can be either hot-applied or cold-applied, depending on the specific project requirements. By implementing a waterproofing membrane on concrete bridge decks, the service life of the structure can be significantly extended. This is because it helps prevent water damage, reduces the need for frequent repairs and maintenance, and improves the overall structural integrity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Waterproofing Membrane with Polyester Scrim Layer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords