PVC Waterproof Rolling Membranes For Roof With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

The P series waterproofing membrane is a heatweldable membrane produced with an integral polyester reinforcement for high strength,for use in a Magical Stone's solution system. Its excellent performance of resistance to plasticizer extraction and migration, extend the product's life and more friendly to environment.

Application Scope

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc

Features and Benefits:

l High Strength

l Hot-air welded seams for long-term performance

l Proven membrane performance

l Excellent resistance to plasticizer extraction and migration performance.

Advantagee

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

9.Excellent Quality+ Competitive Cost+ High Productivity +Brand Management +Good Customer Service

10.Strong tensile strength, high elongation, excellent anti-extreme weather property, suitable for exposed projects with long lifetime and good anti-aging property, can be welded firmly, outstanding root penetration resistance, simple and fast construction without pollution, great plasticity and fast treatment with corners and details, etc.

Actually, for all the features listed like above, I’m sure every waterproofing manufacturer would like to use them for the description of their products. But whether surely their products can live up the standards and fill your requirements, it’s a question.

Packaging:

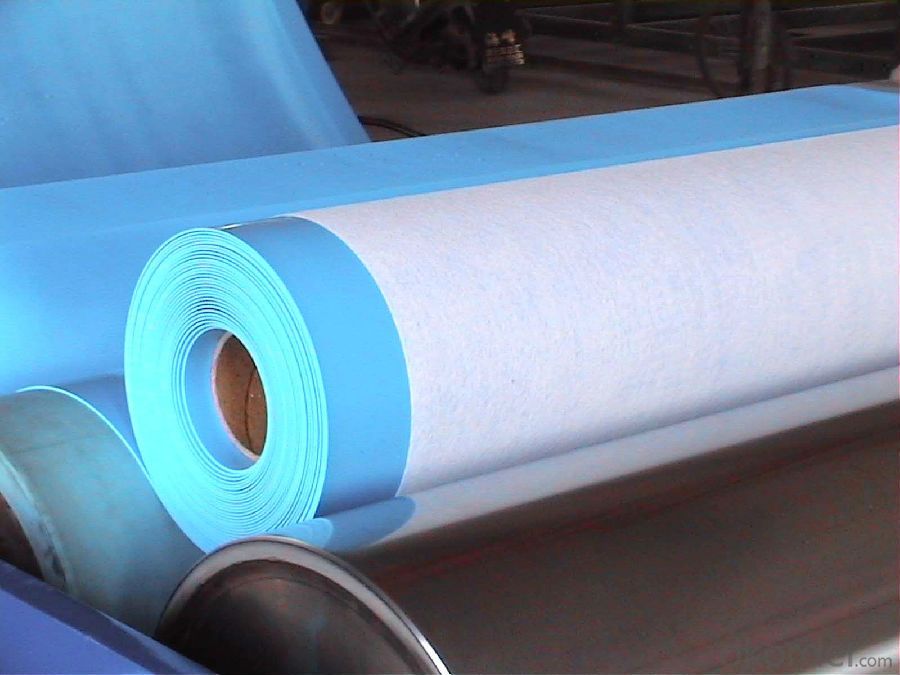

The rolls of P series waterproofing membrane are wrapped in a protective film and strapped to a wood pallet. The P series waterproofing membrane lengths of 15m, 20m, 25m, widths of 1.03m, 2.05m and thicknesses of 1.20mm, 1.50mm, 1.80mm, 2.00mm or customized according to customers requirements.

Technical Parameters

Item | Index | ||||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

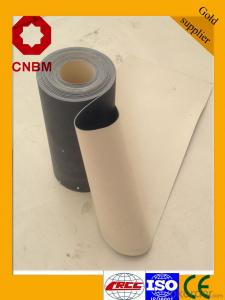

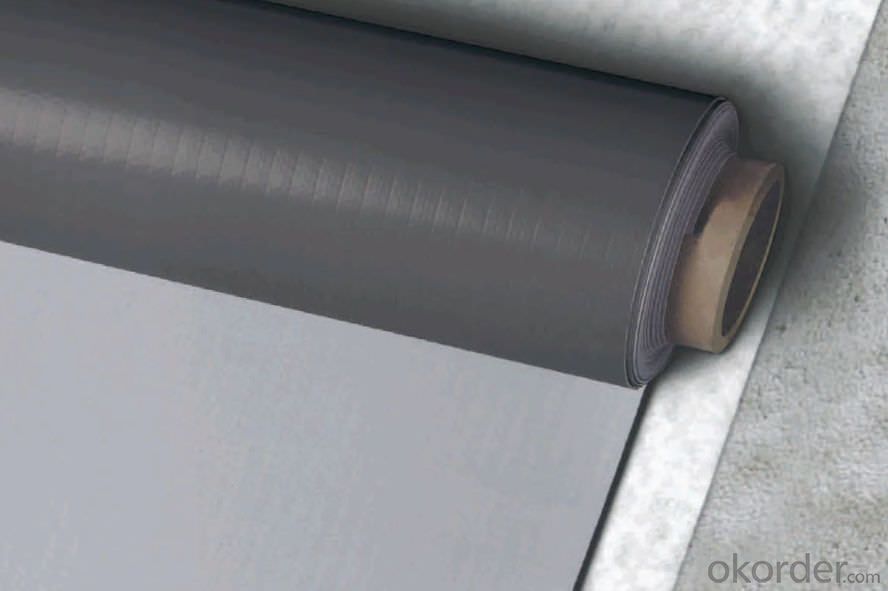

product show

FAQ

Q: What's the de6abf1fe186f8d58506cbcfe46eed814d.jpglivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q:Are waterproofing membranes resistant to punctures?

- Yes, waterproofing membranes are designed to be resistant to punctures. These membranes are typically made from durable materials such as polyvinyl chloride (PVC), thermoplastic olefin (TPO), or ethylene propylene diene terpolymer (EPDM), which are known for their strength and ability to withstand external pressures. Additionally, waterproofing membranes are often reinforced with polyester or fiberglass to further enhance their puncture resistance. However, it is important to note that while waterproofing membranes are designed to be highly resistant to punctures, they may still be susceptible to damage if subjected to sharp objects or excessive force. Therefore, it is essential to handle and install these membranes with care to maintain their integrity and effectiveness.

- Q:Can a waterproofing membrane be used for fire pit areas?

- No, a waterproofing membrane should not be used for fire pit areas. While waterproofing membranes are designed to prevent water penetration, they are not designed to withstand the high temperatures and potential fire hazards associated with fire pits. Fire pit areas require specific fire-resistant materials that can withstand the heat generated by the fire and prevent any potential fire accidents. It is important to use appropriate materials that are specifically designed for fire pit areas to ensure safety and prevent any potential damage.

- Q:Can a waterproofing membrane be used for highway or road projects?

- Highway or road projects can benefit from the utilization of a waterproofing membrane. These membranes are frequently employed in road construction to safeguard the underlying layers against water damage. Serving as a barrier, they effectively ward off water infiltration, thus averting the deterioration of the road structure. Application of these membranes is typically done on areas of high water exposure such as bridge decks, tunnels, and retaining walls. By preventing water from seeping into the road, the waterproofing membrane aids in prolonging its lifespan by mitigating moisture-related issues like cracks, potholes, and erosion. Furthermore, it enhances the road structure's durability and strength, bolstering its resistance against environmental elements. Ultimately, the integration of a waterproofing membrane in highway or road projects delivers long-term protection and ensures the endurance of the infrastructure.

- Q:Can a waterproofing membrane be used for plant rooms?

- Indeed, plant rooms can benefit from the utilization of a waterproofing membrane. These rooms frequently accommodate machinery and equipment that necessitate safeguarding against water and moisture. Employing a waterproofing membrane can effectively avert water-related harm to both the plant room and its enclosed equipment. By establishing a protective barrier, the membrane effectively prohibits the infiltration of water into the walls, floors, and ceilings of the plant room. This becomes particularly crucial in regions prone to water leaks or condensation. Waterproofing membranes are meticulously engineered to endure diverse environmental circumstances, guaranteeing enduring protection for plant rooms.

- Q:Are waterproofing membranes resistant to gasoline?

- Yes, waterproofing membranes are generally resistant to gasoline. Most waterproofing membranes are designed to be chemically resistant and can withstand exposure to various chemicals, including gasoline. However, it is important to note that the level of resistance can vary depending on the specific type of membrane and its composition. Some membranes may offer better resistance to gasoline than others. Additionally, prolonged exposure to gasoline can still potentially damage or degrade the membrane over time, so it is always recommended to take necessary precautions and avoid prolonged exposure to harsh chemicals.

- Q:Can a waterproofing membrane be used for parking garage ramps and driveways?

- Indeed, parking garage ramps and driveways can benefit from the utilization of a waterproofing membrane. Due to their constant exposure to water, moisture, and various environmental factors, these areas are susceptible to structural degradation over time. Nonetheless, the application of a waterproofing membrane establishes a barrier that effectively obstructs water infiltration, safeguarding the underlying concrete or asphalt from deterioration. Consequently, this practice prolongs the lifespan of the ramps and driveways, diminishes maintenance expenditure, and amplifies overall durability. Moreover, the implementation of a waterproofing membrane also deters water from permeating the subterranean parking zones, thereby averting potential water-related harm and ensuring a secure and dry environment for both vehicles and pedestrians.

- Q:DTM.E polyester composite waterproofing membrane, cheaper than the asphalt membrane?

- Ouwei Jianke DTM.E polyester composite waterproofing membrane is the company according to GB50207-2002 "roofing quality acceptance norms", GB50108-2008 "underground engineering waterproof technical specifications", GB50208-2002 "underground waterproofing project quality acceptance norms" and Other waterproof engineering design Widely used in a new type of waterproof material,

- Q:Can a waterproofing membrane be used for a fountain waterproofing system?

- Yes, a waterproofing membrane can be used for a fountain waterproofing system. Waterproofing membranes are designed to provide a barrier against water penetration and are commonly used in various applications, including fountains. They can effectively protect the structure and prevent water leakage, ensuring the durability and functionality of the fountain.

- Q:Can a waterproofing membrane be used for swimming pool coping?

- No, a waterproofing membrane cannot be used for swimming pool coping. Coping refers to the material used to cover the top edges of the pool walls and is typically made of concrete, stone, or tile. It is primarily used to provide a finished look and protect the pool structure from water damage. On the other hand, a waterproofing membrane is a material applied to the surface of a structure, such as a basement or roof, to prevent water infiltration. While both serve the purpose of water protection, they are designed for different applications and are not interchangeable.

- Q:Does a waterproofing membrane require any specific surface preparation?

- Specific surface preparation is necessary prior to the installation of a waterproofing membrane. The quality and condition of the surface play a significant role in determining the success and effectiveness of the membrane. To begin with, the surface must be thoroughly cleaned and devoid of any dirt, debris, oil, grease, or loose particles. This can be accomplished by utilizing a pressure washer, scrub brush, or appropriate cleaning agents. Additionally, any existing coatings or sealants must be eliminated to ensure proper adhesion of the membrane. Furthermore, the surface should be even and smooth. Any uneven areas, cracks, or holes need to be repaired and leveled prior to applying the membrane. This can be achieved by filling the cracks or holes with a suitable filler or patching compound and smoothing it out to establish a uniform surface. Moreover, it is imperative that the surface is completely dry. Moisture can compromise the adhesion and effectiveness of the waterproofing membrane. Therefore, it is essential to ensure the surface is fully dry before commencing the installation. This may involve allowing the surface to air dry or employing appropriate drying methods such as fans or dehumidifiers. In addition to these general surface preparations, specific types of waterproofing membranes may entail additional requirements. For instance, certain membranes may necessitate the application of a primer on the surface before installation. It is crucial to adhere to the manufacturer's instructions and recommendations for the specific membrane being used. Overall, proper surface preparation is vital for the accomplishment of a waterproofing membrane installation. It guarantees optimal adhesion, durability, and performance of the membrane, ultimately preventing water penetration and safeguarding the underlying structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Waterproof Rolling Membranes For Roof With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords