Pvc High quality Ball Valve from China Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Ball Valve Description:

Threaded ball valve is closed is a ball, ball around the center line of the body as a rotation to achieve a kind of open and close the valve.

Ball valve in the line is mainly used for cutting, distribution, and change the flow direction of medium. Two type ball valve, three type ball valve, is widely used in recent years a new type of valve, the valve average installation. And ball valve is a kind of ball valves, threaded pipe connection is screwed connection, and flanged ball valves, welded ball valve, etc.

2. Main Features of the Ball Valve:

• Small flow resistance;

• Simple structure

• Small volume, light weigh

• Small volume, light weigh

• Easy to operate, open and close quickly, facilitate remote contro

• Easy maintenance, sealing ring, which generally remove easy to change

• Full open or full close, sphere and valve seat sealing surface and the dielectric isolation, medium through does not cause the valve sealing surface erosion.

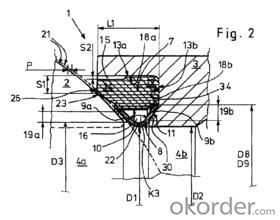

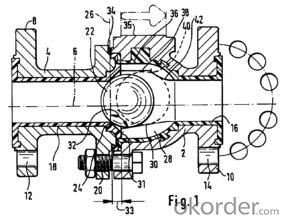

3. Images

4. Ball valve Specification

5.FAQ

1. What's are the characteristics of ball valve?

The distinct feature of a ball valve is the sealing surfaces between the gate and seats are planar, so ball valves are often used when a straight-line flow of fluid and minimum restriction is desired. The ball valve faces can form a wedge shape or they can be parallel.

2. What is the work principle of ball valve ?

The ball valve faces can form a wedge shape or they can be parallel. Ball valves are primarily used to permit or prevent the flow of liquids, but typical ball valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, ball valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Ball valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q:What are the uses and differences of gate valves, butterfly valves, ball valves and other valves?

- The use of the same difference, you can see the shape

- Q:Which direction is the valve? Which direction is it?

- Ball valve: handle and Guan Daocheng 90 degrees for the pass, 180 degrees to open (ie in line with the direction of the pipe open)The gate: clockwise, counterclockwise.

- Q:What are mine valves?

- You want to see what works on the use of what media, in the choice of what type of valve is more appropriate. Shanghai HuquanValve manufacturers, veteran enterprises, trustworthy.

- Q:Can other valves be used instead of 10?

- An elbow, an outer wire, screw down the joint of the hose, the elbow is joined together.

- Q:What does the "Z45T-16" valve mean?

- Z - gate valve4 - flange connection5 - Dark pole, stem non lifting (gate valve structure)T - copper alloy, valve sealing face code16 - pressure code, 1.6MPaMaterial code for grey cast iron valves of nominal pressure less than or equal to PN16 shall be omitted in model preparation.May refer to JB/T 308 valve model compilation method

- Q:Is there any problem with connecting the geothermal valves with other geothermal pipes?

- Material is the same, the fuse will not cause shrinkage when you can use

- Q:What are the main equipments for valve production?

- I know these gate valves, globe valves, plug valves, ball valves, butterfly valves, needle valves, diaphragm valves, check valves, and throttle valves

- Q:1) the valve plate, valve gate valve, the difference (my personal understanding is that if it is on the ball, called the valve, if the valve is called the gate, is actually a meaning in different valve called, please help me understand it right?)2) valve clack. What's the spool?3) the valve seat is welded inside the valve, or is it directly installed inside without welding?4) when opening the valve, if the valve seat is not welded, then, under the pressure of the medium, why not open the seat?.5) excuse me, pressure self sealing (my personal understanding is that when the valve is closed, the valve plate and valve seat depend on the pressure of the media, and they fit together to seal the effect

- 1. can be understood that way2, check valves, stop valves, and throttle valves are called valves3., welding, thread, and there is a cylindrical indentation, as well as plastic deformation press in4, without opening, there is a sphere or other block, open the moment, the pressure will come down, the media through the channel, attack or blocked by the ball, huh, huh5, the pressure self tight refers to the middle flange, where the greater the pressure, the more reliable sealing, within a certain rangeWhen the cut-off valve diameter is less than 150, the medium is low, the inlet is higher and the outlet diameter is greater than 200Some of them are self locking by thread, and some of the globe valves are equipped with locking devices

- Q:Valve difference

- Valve difference, or you should ask the classification of valves, valve classification, there are several sub methods, some according to the model, and some are by use, then each kind of valve is divided into several categories and models. Take the trap for example, it is a kind of valve, and then it is divided into steam traps, air traps, float traps, and so on. If you really want to know the difference between the valve you search the Internet under the classification of the valve, there are a lot of articles, or you directly to the trap inside www.ssfmsh find an article on the valve type article, can not give you a specific address, is not allowed here. You work hard, go find kazakhstan. I hope my answer will be helpful to you.

- Q:Yongde jiekelong valves and valves of the good faith

- Interior decoration is the most cost-effective brand, switches, sockets, Zhejiang, Yongkang, France and Germany electrical appliances. Plumbing valve, Zhejiang, Yongde, Yongkang letter. Bathroom accessories Fujian Nanan Jomoo bathroom.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pvc High quality Ball Valve from China Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products