Printing Tinplate Coils With Prime Quality for 0.26mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Printing Tinplate Coils With Prime Quality for 0.26mm

1.Structure of Description

Printing Tinplate Coils With Prime Quality for 0.26mm is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

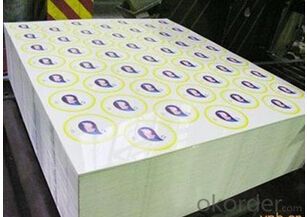

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.31

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. Can you provide the printing surface for tinplates?

Yes, we can, with difference color design.

- Q:How does tinplate impact the ease of opening and closing packaging?

- Tinplate, due to its durability and flexibility, positively impacts the ease of opening and closing packaging. It provides a sturdy and secure enclosure, ensuring that the package remains intact during transportation and storage. Additionally, tinplate's smooth surface allows for effortless opening and closing, making it convenient for consumers to access the contents of the packaging.

- Q:What are the main applications of tinplate in the automotive industry?

- Tinplate is commonly used in the automotive industry for various purposes, including the production of fuel tanks, oil filters, and battery casings. The main applications of tinplate in the automotive sector are primarily due to its properties, such as corrosion resistance, durability, and formability. These qualities make tinplate an ideal material for ensuring the safety and longevity of automotive components.

- Q:What are the challenges faced in the recycling of tinplate?

- One of the main challenges in the recycling of tinplate is the separation of tin from the steel base. Tinplate consists of a thin layer of tin coated on steel, and separating these materials requires specialized equipment and processes. Additionally, the presence of other contaminants, such as paint or coatings, can further complicate the recycling process. Proper sorting and cleaning of tinplate waste is necessary to ensure efficient recycling and minimize the loss of valuable materials.

- Q:Can tinplate be used for packaging fragile items?

- Yes, tinplate can be used for packaging fragile items. Tinplate is a durable material that provides excellent protection against impact and external factors, making it suitable for packaging delicate and fragile items.

- Q:How does tinplate perform in high humidity environments?

- Tinplate performs well in high humidity environments due to its excellent corrosion resistance properties. The tin coating on the steel substrate acts as a protective barrier, preventing moisture from reaching the metal surface and causing rust or corrosion. This makes tinplate a reliable and durable packaging material, especially for food and beverage products, in humid conditions.

- Q:How does tinplate perform in terms of moisture barrier properties?

- Tinplate demonstrates excellent moisture barrier properties due to its inherent corrosion resistance and the presence of a thin tin coating on its surface. This coating acts as a protective barrier, preventing moisture from penetrating the tinplate and maintaining the integrity of the packaged product.

- Q:What are the advantages of using tinplate for automotive components?

- One advantage of using tinplate for automotive components is its high corrosion resistance. Tinplate is coated with a thin layer of tin, which acts as a protective barrier against moisture and oxidation, ensuring the longevity of the components. Additionally, tinplate offers excellent formability, allowing for complex shapes and designs, which is crucial in the automotive industry. Lastly, tinplate is lightweight yet strong, contributing to improved fuel efficiency and overall vehicle performance.

- Q:What are the main challenges in tinplate labeling?

- The main challenges in tinplate labeling include ensuring the label adheres well to the curved surface of the tinplate, maintaining label durability and resistance to moisture and other external factors, achieving accurate and consistent placement of the label, and ensuring the label does not peel or bubble over time.

- Q:How is tinplate used in the construction industry?

- Tinplate is commonly used in the construction industry for various applications. It is primarily utilized for roofing and cladding purposes due to its durability, corrosion resistance, and aesthetic appeal. Tinplate sheets are often employed in the construction of warehouses, industrial buildings, and residential structures as a protective outer layer. Additionally, tinplate can be used for decorative purposes, such as wall panels or ceiling tiles, adding a sleek and modern look to buildings.

- Q:How does tinplate perform in terms of heat transfer?

- Tinplate performs poorly in terms of heat transfer due to its low thermal conductivity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Printing Tinplate Coils With Prime Quality for 0.26mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords