Prepainted Steel Coils/Manufacture Anticorrosion Parts of Cars (PPGI)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Detailed Specifications of Prepainted Steel Coils/Manufacture Anticorrosion Parts of Cars (PPGI)

| Product | Prepainted Steel Coils/Manufacture Anticorrosion Parts of Cars (PPGI) |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Applications of Prepainted Steel Coils/Manufacture Anticorrosion Parts of Cars (PPGI):

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

.Manufacture anticorrosion, industrial and roof boarding,roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils.

.Corrosion resistant parts of cars.

.Food storage, meat and aquatic products’ freezing and processing equipment.

.The equipments to store and transport materials, and packing implements.

3. Image :

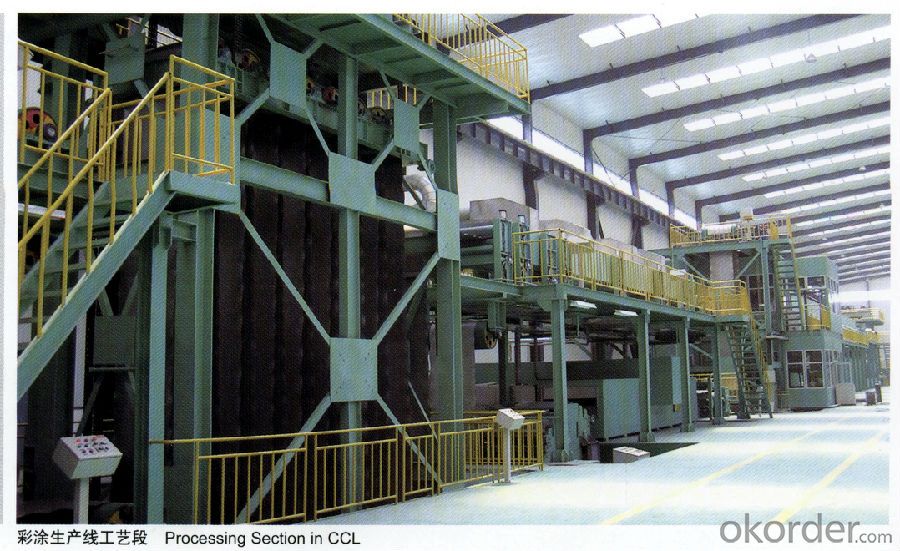

production Line:

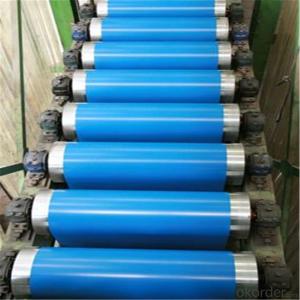

production show:

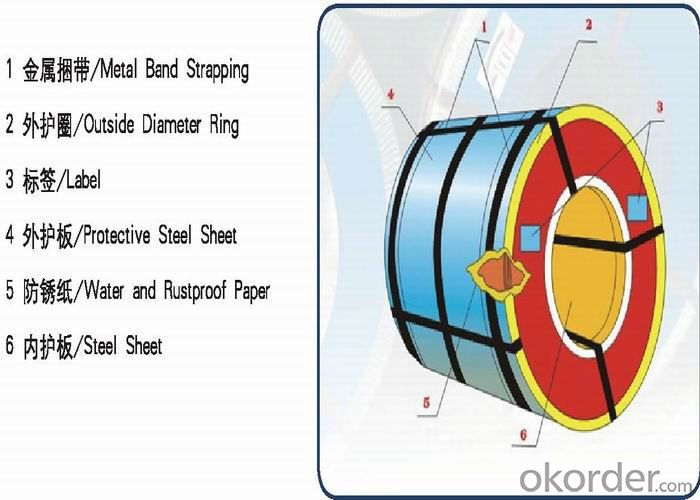

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1Year for the whole light. Warranty is based on correct storage, installation, using and mainten anc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as so on as possible.

- Q:What are the different methods of joining steel coils?

- There are several methods of joining steel coils, including welding, using mechanical fasteners, and adhesive bonding. Welding is a common technique that involves melting and fusing the edges of the coils together using heat. Mechanical fasteners, such as bolts or screws, can also be used to secure the coils together. Additionally, adhesive bonding involves using a strong adhesive to bond the coils together. Each method has its own advantages and considerations depending on the specific application and requirements.

- Q:What are the common defects in steel coils?

- Some common defects in steel coils include surface defects like scratches, rust, and pits, as well as internal defects like cracks, laminations, and non-uniform thickness. Other defects may include coil set, which is a curvature in the coil, and edge wave, which is a distortion along the edges of the coil.

- Q:I moved into a house which has a steel front door.When I touch the door it feels very cold to the touch in the winter.There is a storm door also and the weather stripping looks good.Cold air from the door is entering the lower level.The house is about 20 yrs old.

- Now a days crime has increased a lot, so we have to take protection and when the protection came to our house there came steel doors. The best ever protection in our houses. Source - www.scoop.it/t/qualitas-steel-doors

- Q:who are the 7 best steel guitar players ever?

- 1.Jerry Byrd 2. Buddy Emmons 3. Jimmy Day 4. LLoyd Green 5. Pete Drake 6. Hal Ruggs 7. Welbon Myrik

- Q:I'm in the process of buying a new car, and wondering if there are more benefits from Aluminum tire rims over Steel. Aluminum wheels cost more, but you'd think that steel would last longer. Are Aluminum wheels just for looks?

- If you got money to waste get the aluminum. Practicality is the steel wheels.

- Q:Can steel coils be bent or shaped?

- Yes, steel coils can be bent or shaped due to their flexibility and malleability.

- Q:Does anyone have any idea where I could get a necklace that has the British Steel by Judas Priest logo?

- Bristish Steel...ROCKS!!! Ebay is a good suggestion but if its something custom like that you could always bring in a drawing or picture to a jeweler and they can source it for you ;) I did something similar and the jeweler actually made it custom for me.... just a suggestion :) Good Luck!

- Q:What are the main factors that affect the paint adhesion on steel coils?

- The main factors that affect paint adhesion on steel coils include surface preparation, cleanliness, and the presence of contaminants such as oil, grease, or rust. Other factors include the quality of the paint itself, the application method, and the curing process. Additionally, the type of steel and its surface condition can also influence paint adhesion.

- Q:How are steel coils used in the production of doors and windows?

- Steel coils are vital components in the production of doors and windows due to their strength and versatility. These coils are typically made from high-quality steel and are used in various stages of the manufacturing process. Firstly, steel coils are used to create the frame of the doors and windows. The coils are unrolled and cut into specific lengths, depending on the desired dimensions of the frame. The steel is then bent and shaped into the required frame design, ensuring that it is strong and durable. Next, the coils are used to produce the panels or glass holders for the doors and windows. The steel is cut and formed into the desired shape, and then it is either welded or attached to the frame. This ensures that the doors and windows have a sturdy structure and can handle the weight and pressure of the glass or panels. Additionally, steel coils are also used to create the hinges and other hardware components of the doors and windows. The coils are cut and shaped into the necessary parts, ensuring that they are strong enough to support the movement and functionality of the doors and windows. Furthermore, steel coils can be used for decorative purposes. They can be embossed or coated with different finishes to enhance the appearance of the doors and windows. This allows for a wide range of design options, enabling manufacturers to create doors and windows that suit various architectural styles and preferences. In summary, steel coils play a significant role in the production of doors and windows. They are used to create the frame, panels, hinges, and other hardware components, ensuring strength, durability, and functionality. Additionally, they can be used for decorative purposes, allowing for customization and aesthetic appeal.

- Q:Got small (.177) bb gun for fun with my son...From the manual:'Steel shot will fire at a higher velocity then lead shot with with the same muzzle energy. As a result, more caution is required when using steel shot because of a greater hazard of ricochet. Lead, because of its lower velocity, usually has less penetrating power and is less likely to ricochet.'Are you agree with that? ;)

- steel is made of iron mainly (and carbon) its density is 7.86 g/cm? approximately. and lead has density=11.4 g/cm?. so, if have same volume and shape steel will have less mass and thus will have greater velocity for same muzzle energy. I agree the manual. for more information on ricochet

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Steel Coils/Manufacture Anticorrosion Parts of Cars (PPGI)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords