Pre-stressed Concrete Floor Slabs Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-stressed Concrete Floor Slabs Making Machine

1. Structure of Pre-stressed Concrete Floor Slabs Making Machine:

Products of this series (non-circular and circular cored) are the ideal machines for making building materials on constructions of large span and heavy load bearing in factories, schools, hospitals, shopping centers, office building and homes.

Our hollow core slab machines have the advantages of reasonable design, easy operation, convenient maintenance and long working life. Slab length can be achieved to 4.2m to 18m; width of 600mm, 900mm and 1200mm; thickness of 120mm, 150mm, 180mm, 200mm, 250mm, 300mm, 380mm.

The hollow core slab machines are working on the long-line table, tensioning the high-strength and low-relaxation steel strand first, and using the pushing work method to form the concrete hollow core slab. The slabs which being formed have the advantages of smooth surface and high-density structure.

2. Main Features of Pre-stressed Concrete Floor Slabs Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

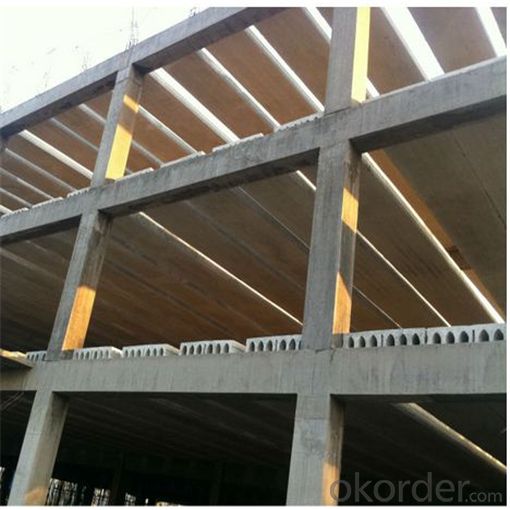

3. Pre-stressed Concrete Floor Slabs Making Machine Images:

4. Pre-stressed Concrete Floor Slabs Making Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q:I'm not very fond of walking on the treadmill for half an hour or going to the gym and using those big, scary machines. O.oBut I really want to lose weight and stay healthy, just without all that metal tearing me apart. What kinds of exercises are best for losing weight without the use of machines?

- I go on walking trails.

- Q:Like Skynet from Terminator, there is a word they use besides quot;self aware.quot; A little help?

- Bird okorder /

- Q:i need help w/ a science question lol....:] help please! thnx! o and also, the 1st question is more important, but if u know this one, it would help too: How is friction a factor in outer space?

- rather some what we do is actual extravagant and likely isn't activities we do interior the destiny as they are going to be called asinine and wasteful. i imagine such issues because the internet will make the great united states of america state out of date, if truth be told its out of date now, any united states of america more suitable than Portugal will probably split into smaller countries. there'll be extra decentralization and emphasis on close by-ness, and we would properly be placed lower back in our gardens for far of what we eat on a on a daily basis foundation, even severe tech indoor all 12 months gardens with tiny robotic pollinators, i imagine some English crew of chaps actual made robotic bees many years in the past. 3-d printers would made stuff out of superior biodegradable plastics derived from cotton or algae. and robotic prostitutes will cater to each and each of the deviants, and if truth be told each body. no longer advantageous what human beings will actual do, yet those issues would replace the way we artwork. there is resistance in this regard, although that is idea that folk would take care of to get a lot of what we deem college preparation from homestead, you may already pay interest to three lectures on podcast.

- Q:Framework for oil well drilling machinery?

- Derrick

- Q:Such as in terms of construction equipment like a crane, what is the maximum amount of weight that can be lifted by any existing machine?

- A crane's limitation is defined as metre-tonnes, because it is the moment that creates the limitation of the crane lift. A crane does the same amount of work to lift 50 tonnes at 10 metres as it does to lift 100 tonnes at 5 metres. That being said; I believe the largest single lift was perfromed by one of forty-two Lampson Tranis Lift IIs in Corpus Christi TX. The actual load was 1000 tonnes. And this just happens to be a MOBILE unit, on top of everything else!

- Q:Presented here are selected transactions for Snow Company for 2012.Jan. 1Retired a piece of machinery that was purchased on January 1, 2002. The machine cost $66,300 on that date and had a useful life of 10 years with no salvage value.June 30Sold a computer that was purchased on January 1, 2009. The computer cost $31,200 and had a useful life of 5 years with no salvage value. The computer was sold for $12,480.Dec. 31Discarded a delivery truck that was purchased on January 1, 2007. The truck cost $53,000 and was depreciated based on an 8-year useful life with a $6,300 salvage value.Journalize all entries required on the above dates, including entries to update depreciation, where applicable, on assets disposed of. Snow Company uses straight-line depreciation. (Assume depreciation is up to date as of December 31, 2011.)

- Jan. 1 Retired a piece of machinery that was purchased on January 1, 2002. The machine cost $66,300 on that date and had a useful life of 10 years with no salvage value. After 10 years the machinery is fully depreciated. Dr Accumulated Depreciation--Machinery 66,300 Cr Machinery 66,300 June 30 Sold a computer that was purchased on January 1, 2009. The computer cost $31,200 and had a useful life of 5 years with no salvage value. The computer was sold for $12,480. Six months of depreciation has accumulated since the beginning of the year. 31,200 / 5 x 6/12 = $3,120 to update depreciation Dr Depreciation Expense--Computer 3,120 Cr Accumulated Depreciation--Computer 3,120 31,200 / 5 x 3 1/2 = 21,840 total accumulated depreciation at time of sale Dr Cash 12,480 Dr Accumulated Depreciation--Computer 21,840 Cr Computer 31,200 Cr Gain on Sale of Computer 3,120 Dec. 31 Discarded a delivery truck that was purchased on January 1, 2007. The truck cost $53,000 and was depreciated based on an 8-year useful life with a $6,300 salvage value. (53,000 - 6,300) / 8 = $5,837.50 to update depreciation Dr Depreciation Expense--Truck 5,837.50 Cr Accumulated Depreciation--Truck 5,837.50 5,837.50 x 6 = 35,025 total accumulated depreciation at time of sale Dr Accumulated Depreciation--Truck 35,025 Dr Loss on Disposal 17,975 Cr Truck 53,000

- Q:what are working men and women who oporate machinery called?

- Machine operators

- Q:I am planning to setup a juice processing unit and therefore need help and info on the plant and machinery either on turnkey basis or upfront selling along with technology transfer.

- I okorder

- Q:plz help! its my homework :P ugh. thanks guys xD

- The Oxford American Writer's Thesaurus does not mention any antonyms. The opposite of a machine might be human labor. Did you mean synonym? (meaning similar) ... If so, apparatus ,hardware, gear, mechanism, gadgetry, tool, engine

- Q:Do engineering technicians get to invent and patent ideas within large companies, or is this typically reserved for the mechanical engineers?

- Anyone can patent machinery. The question is, will a company be willing to pay a technician to spend his time inventing? Probably not. As a prior post indicated, the responsibility for solving the porblem, at least theoretically, usually belongs to the engineer. In good engineering teams, the problems are solved by more than one person. To that end if the idea is patented, everyone's contirbution should be documented. It usually comes down to a company's willingness to risk the cost of a patent on the potential payback. Fo that sort of risk assessment, they want to undertsand the magnitude of the gamble. Engineers are pretty good at detailing what the risks are and getting the approval for patents.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-stressed Concrete Floor Slabs Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords