Pre-Insulated Aluminum Panel Insulated Ductwork Aluminio Gofrado

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRE-INSULATED ALUMINIUM Panel Insulated Ductwork Aluminio Gofrado

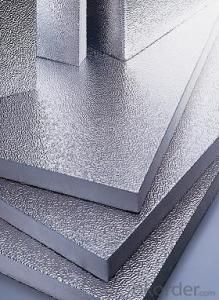

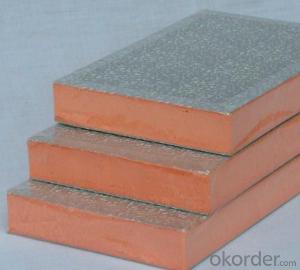

1.Structure of PRE-INSULATED ALUMINIUM Panel Insulated Ductwork Aluminio Gofrado

Air ductwork supply is pre-insulated aluminum panels constructed of both aluminum and Poly-isocyanurate. The sandwich panels are comprised of expanded Poly-isocyanurate rigid foam board, faced on both sides by aluminum foil.Ducting is the key part of any central air-conditioning system. It is similar in function to the arteries and veins in the human body as it helps in regulating the temperature in a building. The material used for making ducts for air-conditioning is constantly evolving in order to satisfy the demand for higher thermal efficiency, eco-friendliness, and increased energy savings. Many different materials and systems such as magnetite composite, PVC and so on have been developed as alternatives to the galvanized sheet metal used traditionally. But pre-insulated ducting materials is by far the most popular ducting system in use today. It is essentially a panel made with an insulating material such as PIR (Polyisocyanurate), PUR (Polyurethane) or Phenolic foam material sandwiched in between two layers of aluminium foil. Such a foam panel is easier than traditional galvanized sheet metal to manipulate for complex designs and lighter than its predecessors for installation. These qualities in addition to the fact that it has a much higher thermal efficiency than galvanized sheet metal make it an ideal material for fabricating Airconditioning ducts in harsh climates like the Gulf. Its application has been gradually extended to every type of air distribution system: industrial and commercial.

For construction of air ducting in HVAC systems, the Polyisocyanurate (PIR), PUR (Polyurethane) and/or Phenolic foam panel with 45kg/m3 density, coated with 80/80µm thick embossed aluminum foil have two panel types:

The air ducts fabricated using ALU 80/80 panels can be installed in plants:

with air speed up to 15m/s

with pressure up to 1000Pa

indoor

The air ducts fabricated by using ALU 80/200 panels can be installed in plants:

with air speed up to 35m/s

with pressure 1750Pa

outdoor

2.Main Features of PRE-INSULATED ALUMINIUM PANELS Insulated Ductwork Aluminio Gofrado:

Air Duct Panel / Pre-insulated Duct Panel / HVAC Duct Panel :

HVAC Aluminum Foil Duct Board

1. Be used for HVAC Duct system;

2. BS 476 Part 6&7 Class 0.

3. Low thermal conductivity.

3. PRE-INSULATED ALUMINIUM Insulated Ductwork Aluminio Gofrado

Images

Our embossed aluminum sheet/Coil series include:

1.diamond embossed aluminum sheet/Coil

2.orange peel embossed aluminum sheet/Coil

3.stucco embossed aluminum sheet/Coil

4. PRE-INSULATED ALUMINIUM Insulated Ductwork Aluminio Gofrado

Specification

Air-conditioning Areas Exposed to weather

Thickness of panels 20 Mm 30 Mm

Thickness of aluminum 80/80 Microns 80/200 Microns

Density of the foam 44-48 Kg/m3 42-48 Kg/m3

Finishing of aluminum Embossed Embossed

Dimension Length: 4meter Width: 1.2meter

Note: Both sides of the aluminum foil are lacquered with a 3g/m2 weatherproof and ultraviolet ray protection polyester lacquer.

Certificate: FORM A, CO ,FORM E ,FORM B ,MTC, SGS and ROHS(client paid for it), MTC

Surface Quality: without any dent, scratches, oiliness , oxidation .

Chemicial composite and Machinary Property: Meet with GB/T, JIS,ENAW, ASTM standard

Month Capacity: 5000MT/month

exporting port: Tianjin, Shanghai

payment: TT or LC at sight

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long for your delivery time?

Commonly 30 working days can be served. If you need the products urgently, we can shorten the delivery time into 20 days.

3. Where the Panels can't be used?

As extractors in the kitchen, as chimneys for smoke or chemical laden smoke

As transportation for solids

Outside temperature range -35ºC and +110ºC

Air speed >15m/s for 20mm thick panel and >35m/s for 30mm thick panel

when the negative or positive pressure inside the duct is: 20mm thick panel >1000Pa and 30mm thick panel >1750Pa

- Q:Development prospect of aluminium foil

- Introduction of several key aluminium foil products(I) air conditioning foilThe air conditioner foil is a special material for the heat exchanger fin of an air conditioner, and an early air conditioner foil is a plain foil. In order to improve the surface properties of the plain foil, an anticorrosive inorganic coating and a hydrophilic organic coating are applied before forming to form hydrophilic foil. Hydrophilic foil accounts for 50% of the total amount of air conditioning foil, and its use ratio will be further improved. There is also a hydrophobic foil, so that the fin surface has hydrophobic function, prevent condensation water adhesion. Because of the hydrophobic foil, the technology of improving surface defrosting needs to be studied further, and the actual production is very little.The thickness of the air conditioner foil is 0.1mm to 0.15mm. With the development of technology, air-conditioning foil has further thinning trend, Japan's leading product thickness of 0.09mm. In the thin state, aluminium foil to have excellent formability, microstructure and mechanical properties of metallurgical defects must be uniform, less small anisotropy, and high strength, good ductility, uniform thickness, good flatness. Air conditioning foil specifications and alloy is relatively single, suitable for mass production, but its market season is strong, for air-conditioning foil professional manufacturers, it is difficult to solve the peak season demand and off-season demand almost no contradiction.Due to strong market demand, in recent years, China's air-conditioning foil production capacity and technology level unceasing enhancement, has formed a large and small, high and low production of air foil enterprise group, some large enterprises such as China aluminum, Bohai aluminum products quality has reached the international advanced level. Because of the excessive domestic production capacity, the market competition is extremely fierce.

- Q:I want to burn a complex pattern into a round piece of wood (about 1quot; diameter), but I'm not sure how to create a templateI've tried cutting a hole in some aluminum, and then torching the wood through the shape I cutIt worked decently, but it's difficult to make precise cuts in the aluminum-especially with small shapesIs there a better material I could use as a template? If not, what should I use to make complex cuts in the aluminum?

- A Comforter is smaller than a Quilt or blanket and usually stuffed with feathersA Duvet is a cover for a comforterQuilts are/were made from left overfabric.That was pieced togetherI think you know what a blanket is.

- Q:I need to know what it is made of and fast for scienceSome sites are say it is tin and some aluminumIs it tin+aluminumtin foil? PLEASE HELP FAST!!!!!! : )PS- And I know this is a stupid question, and you might be thinking quot;duhquot; but I need to be positive and sure this is the right answerA link would help A LOT too: ) Thanks again! You guys rock!!!

- Yeah I can for heroin get Imodium,, it deals with the diarrhea and it has an ingredient that comes from the opiate plant get a bunch of gatoraid or a drink like that,,, you need to stay fully hydrated if you can get hold of anything like xanex, valium,etcit will help you because it's almost impossible to sleep for daysYou legs are going to cramp up basically it's like having the flu x 100 for a week, and then months to sleep right take vitamins if you are kicking heroin it will last about a week,,, but with the stuff I listed at at least you won't feel like you wish you would die for pills it all depends on what and how much and for how long.,,,, anything less than about 40mg a day of oxy 99% will be in your head,,,, even it you are around the 60mg do the same as for heroin but it won't be even close to how bad it is,,,, the hard part is really wanting to stop,,, that's 100% of what will get you through themGood luck withdrawls are an addict worse nightmare,,,, if you are hooked bad you will wish you never heard the word opiate ps: you are doing something that you will thank yourself for the rest of your life,,,, and I'm an anti drug freak,,, I've kicked heroin and methadone,, thanks to a drunk driver and doctors taking too long to figure it out so good luck,, you really are doing the right thing,,, if you can't do it on your own,, which about 60% don't,, and if you are really strung out bad get into a methadone clinic,, it makes it far easier and you control it

- Q:how long do you think it would take lemon juice to eat through a sheet of tin foil?

- Aluminum foil? I've had lasagna and rigatoni both eat through a baking pan (you know, those cheap foil ones for turkey that are like a nickel around thanksgiving)It only took like 3 days in the fridgeI don't think tomatoes are as acidic as lemons and the pan was heavier than foil (but not that much more)So I'm gonna say about 3 days.

- Q:so im getting a 2010 kx250f and i want to make it look good so should i paint the frame and if so what color

- I would just leave it bare aluminum, I use a scotch brite pad on mine everytime I wash the bike and the frame always looks brand newPainting the frame will leave it looking like the old steel frames in a few rides, even powder coating won't last foreverI personally think the bare aluminum is a nice look.

- Q:mkay so i bought a hookah.how do i light the cole's?with a lighter, match, what?and i dont get how it burns the hookah when you put the hookah in the bowl, put aluninum foil on it covering the bowl (make little wholes in the foil, and put the cole on top.i dont get how it lights the hookah?and how long does it take the light the hookah?thanks guys.

- It depends what kind of coals you buyIf you buy the quick light ones or whatever you can use a lighter and it'll start sparking and light itselfBut if you don't get the quick light ones you can just put it on the stoveI always put them on the stove, even the quick light ones I don't really understand what you mean by the second partBut you put the aluminum foil over the bowl after you put the tabacco in the bowl (make sure the shiny side is facing the tabacco) and then you poke holes in the foil and put the coal(s) on topThe heat from the coal goes through the wholes and reflects off of the shiny side of the foil and hits the tabaccoDoes that help at all?

- Q:you know wash a salmon after fishing ? i don't know how can i do't because today whent my firs fishing day and?

- OK, here is the thingAll insulation can be a fire hazardThe R rating on fiberglass, however, is much better than woolAnd it is easier to lay downI would go with an R13 Fiberglass, just make sure that when you do lay it down that you wear a mask over the mouth and nose, and get some painter's sleeves to cover your armsDo not scratch yourself as the glass will get into your skin and you could cut yourselfAfter you are done, make sure that you first that a very hot shower for about 10-15 minutes, and then switch it straight to cold, this way it allows your body to sweat out the glass and then the cold shower will shut your pores back up to insure that the glass won't get back inGood luck.

- Q:I have been looking at crafts that use old chip bags to make new things out of (bags, purses, wallets.) Pretty much all the ones I have looked at have a laminated look to them and also in the instructions at some point they say to laminate the old bagsHow is this done? Do you have to bring them to some store or shop and have someone else do it for you or is there a way you can do it at home? Thanks!

- YES! Its ok for anyone to sleep or camp outdoorsThough since she is under 18 it is best if she went with many other people and there was at least one adult aroundJust make sure you have food, tent, rain gear, sleeping bag, cooking supplies, cold and hot weather stuff, and waterYou could call the campground you are staying at and ask what they recomand that you bring

- Q:1.why is the earth not perfectly round? 2.what are some of the more common element composing the earth? 3.what cause the interior of the earth to be hot and how hot is it? 4.what is covection?what are some other example of convection beside hot soup?5.what is the relation between rising and sinking material in the earth's interior and subduction and riping?6.when it is summer in Autralia , what season is it in new york? it is april in Paris7.what is a precession?what are some of its possible consequence.8.what is the mid-atlantic ridge? 9.would a year on the planet neptune be longer or shorter than on earth year?

- Try asking this question over in math and science

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-Insulated Aluminum Panel Insulated Ductwork Aluminio Gofrado

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords